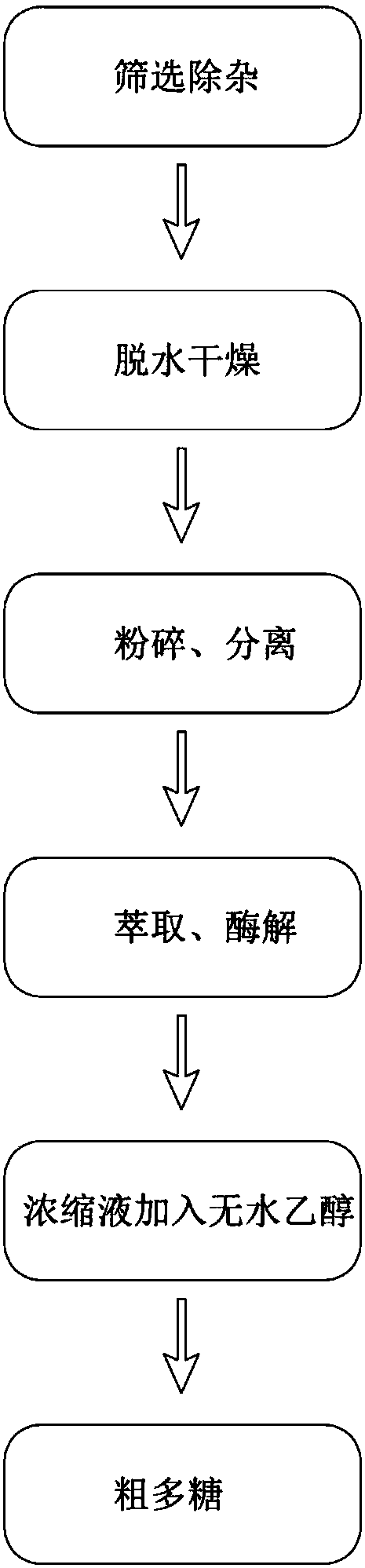

Extraction process of lycium barbarum polysaccharide

An extraction process, Lycium barbarum polysaccharide technology, applied in the field of biological extraction and separation, can solve the problems of polysaccharide degradation, polysaccharide bioactivity destruction, low yield, and long time consumption, and achieve high extraction efficiency, short extraction time, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

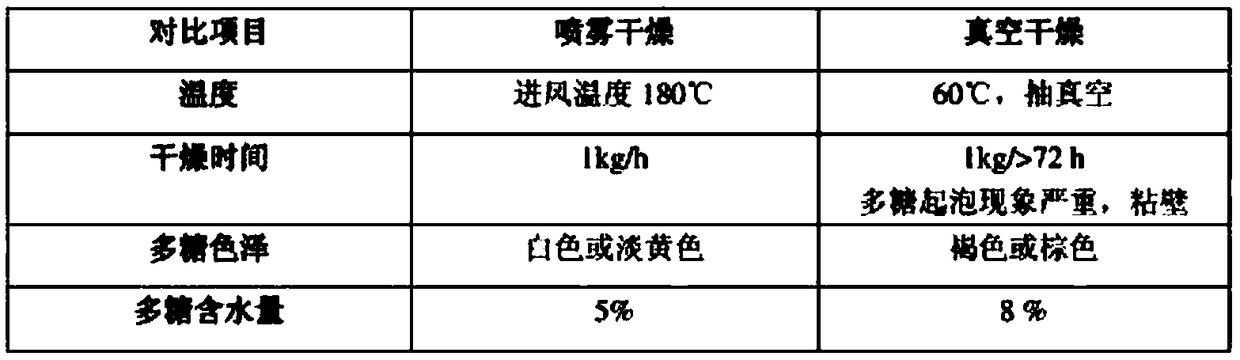

Method used

Image

Examples

Embodiment 1

[0039] Screen 100g of high-quality wolfberry fruits produced in Zhongning, Ningxia, and place them in vacuum-drying at 50°C for 24 hours, crush the dried wolfberry fruits through a coarse particle crusher, and then separate the pulp powder and wolfberry seeds through a three-stage sieve; crush and sieve at room temperature Conditions are carried out, the wolfberry powder is added to petroleum ether for extraction, the defatted powder is vacuum-dried at 60°C to constant weight; the defatted powder is added to a compound enzyme solution for extraction, the compound enzymes are cellulase and papain, and the compound enzyme configuration method is: 0.1mol / L citric acid and sodium citrate solution is configured as a Ph6 buffer solution, cellulase and papain are dissolved in the buffer to obtain a compound enzyme solution, and the degreasing powder is added to the compound enzyme solution for leaching, and the temperature must be lowered to 45°C in advance, and then leaching Incubat...

Embodiment 2

[0041] Screen 100g of high-quality wolfberry fruits produced in Zhongning, Ningxia, and place them in vacuum-drying at 50°C for 24 hours, crush the dried wolfberry fruits through a coarse particle crusher, and then separate the pulp powder and wolfberry seeds through a three-stage sieve; crush and sieve at room temperature Conditions are carried out, the wolfberry powder is added to petroleum ether for extraction, the defatted powder is vacuum-dried at 60°C to constant weight; the defatted powder is added to a compound enzyme solution for extraction, the compound enzymes are cellulase and papain, and the compound enzyme configuration method is: 0.1mol / L citric acid and sodium citrate solution is configured as a Ph8 buffer solution, cellulase and papain are dissolved in the buffer to obtain a compound enzyme solution, and the defatted powder is added to the compound enzyme solution for leaching, and the temperature must be lowered to 45°C in advance, and then leaching Keep warm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com