Preparation method and application of nanometer titania thin film

A nano-titanium dioxide, thin film technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as easy cracking and uneven film surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

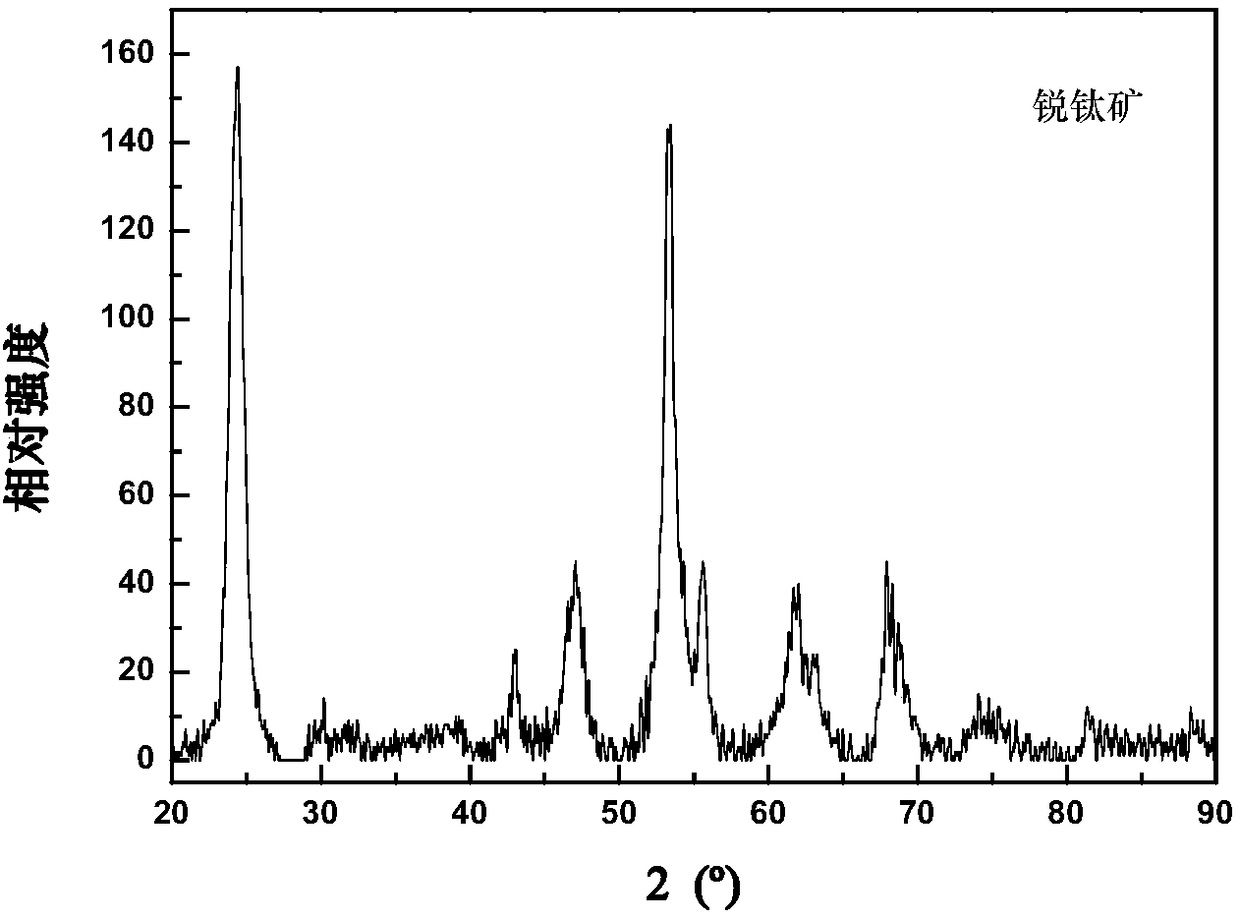

[0030] The invention provides a kind of preparation method of nano titanium dioxide film, comprises the following steps:

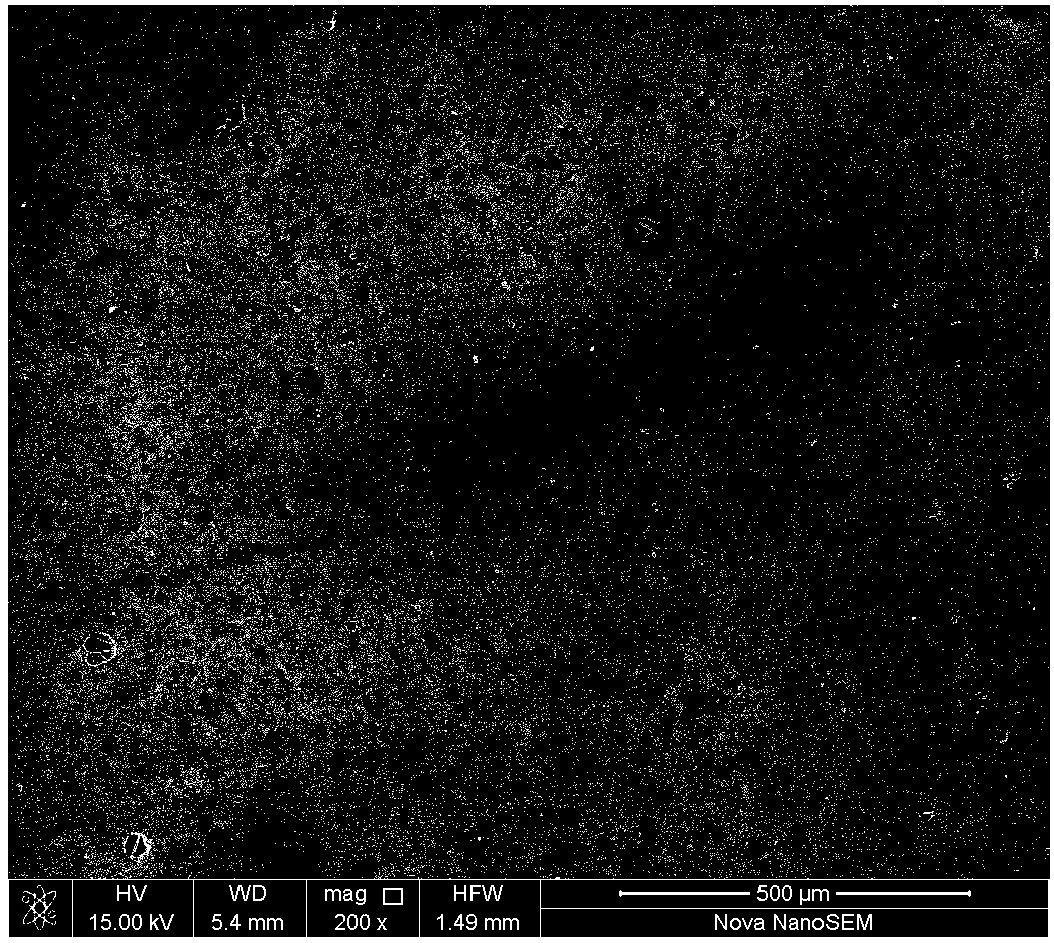

[0031] (1) The substrate is sequentially polished by sandpaper, cleaned with absolute ethanol and electropolished to obtain a pretreated substrate;

[0032] (2) The inhibitor is mixed with water and absolute ethanol to obtain an inhibitor solution, which is added dropwise to the absolute ethanol solution of titanium alkoxide, and then mixed with polyethylene glycol 2000 to obtain TiO 2 coating sol;

[0033] (3) the pretreatment substrate that described step (1) obtains is immersed in the TiO that described step (2) obtains 2 Pull coating in the coating sol to obtain nano-titanium dioxide film precursor;

[0034] (4) drying and annealing the nano-titanium dioxide film precursor obtained in the step (3) successively to obtain a nano-titanium dioxide film;

[0035] There is no time limit for steps (1) and (2).

[0036] In the invention, the substrate is p...

Embodiment 1

[0064] (1) Cut the aluminum alloy into a size of 10×10×3 mm by wire cutting. The surface is polished step by step with 200#, 400#, 600#, 800#, 1000# sandpaper until the surface scratches are basically in one direction, then ultrasonically cleaned with alcohol for 20 minutes, and dried for later use. A perchloric acid alcohol solution with a mass concentration of 20% was prepared, and the polished aluminum alloy was electrolytically polished using the perchloric acid alcohol solution. The electropolishing uses a 20V DC power supply, and the polishing time is 60s. After electropolishing, ultrasonically clean with deionized water and alcohol for 20 minutes respectively, and dry for later use.

[0065] (2) Measure 15 mL of tetrabutyl titanate, add 30 mL of absolute ethanol, record it as solution A, put it on a magnetic stirrer and stir for 30 min. Then measure 3mL of concentrated nitric acid and 4mL of deionized water, add them to 15mL of absolute ethanol, and record it as solut...

Embodiment 2

[0074] (1) Cut the aluminum alloy into a size of 10×10×3 mm by wire cutting. The surface is polished step by step with 200#, 400#, 600#, 800#, 1000# sandpaper until the surface scratches are basically in one direction, then ultrasonically cleaned with alcohol for 20 minutes, and dried for later use. A perchloric acid alcohol solution with a mass concentration of 20% was prepared, and the polished aluminum alloy was electrolytically polished using the perchloric acid alcohol solution. Electropolishing uses a 20V DC power supply, and the polishing time is 80s. After electropolishing, ultrasonically clean with deionized water and alcohol for 20 minutes respectively, and dry for later use.

[0075] (2) Measure 20 mL of tetrabutyl titanate, add 40 mL of absolute ethanol, record it as solution A, put it on a magnetic stirrer and stir for 40 min. Then measure 5mL of concentrated nitric acid and 6mL of deionized water, add them to 20mL of absolute ethanol, and record it as solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com