High-temperature high-pressure preparation method of zinc selenide polycrystalline bulk material

A high temperature and high pressure, zinc selenide technology, applied in the direction of polycrystalline material growth, chemical instruments and methods, crystal growth, etc., to achieve the effect of shortening the preparation cycle and sintering time, simple process flow, and optimizing optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

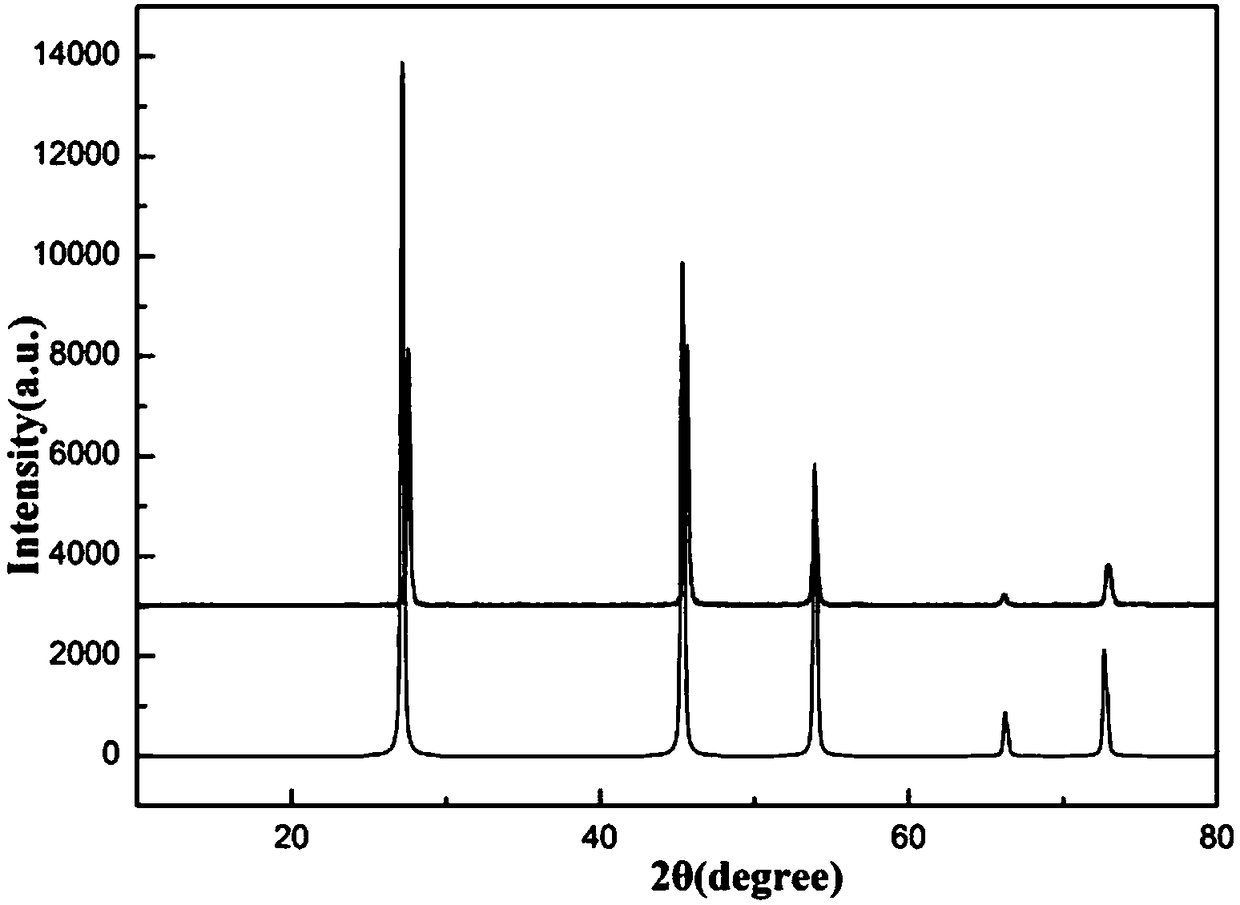

[0028] Fully mix the analytically pure selenium powder (Se) with a particle size of 1 to 5 microns and the zinc powder (Zn) with a particle size of 1 to 5 microns at a molar ratio of 1:1, use a hydraulic press to form the powder, and then put the sample into the synthesis chamber ;The graphite heat pipe is used in the assembly chamber, pyrophyllite is used as the insulation material, and hexagonal boron nitride is used to protect the chamber. The synthesis pressure is 3.0GPa, the synthesis temperature is 1300K, and the heat preservation and pressure holding time is 15 minutes. After the heating is stopped, the sample is naturally cooled to After decompression at room temperature, the specific X-ray diffraction results of zinc selenide prepared under this condition are shown in figure 1 , the transmission energy spectrum results are shown in Figure 6 .

Embodiment 2

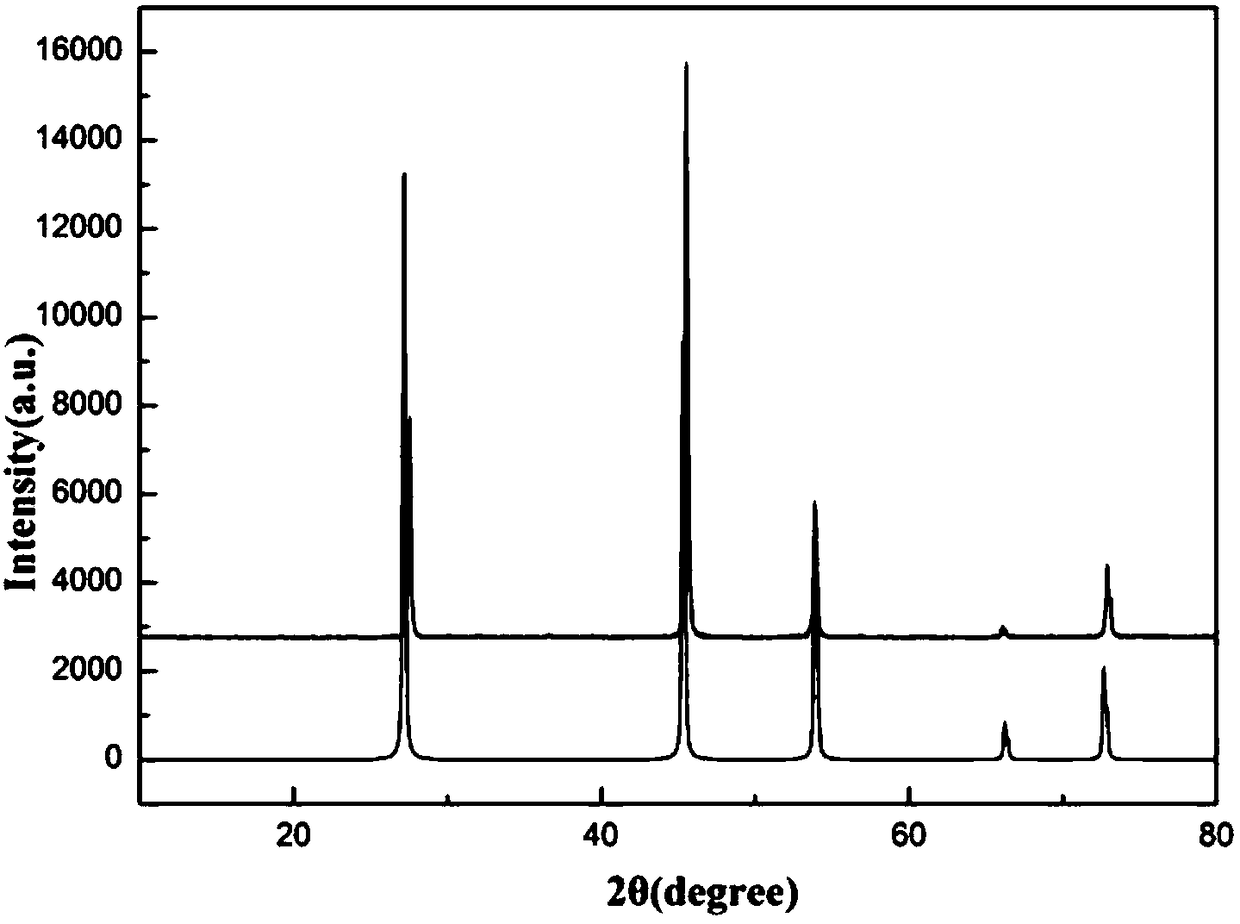

[0030] Using the same raw materials as in Example 1, mixed according to the molar ratio of 1: 1, the powder sample was compressed and formed using the same assembly as in Example 1, the synthesis pressure was 3.0GPa, the synthesis temperature was 1300K, and the pressure holding time was 30 minutes. After the heating was stopped, the sample was naturally cooled to room temperature and then the pressure was released. Under this condition, pure phase zinc selenide was prepared. Combining the above two examples, it can be known that increasing the time can improve the crystallinity of zinc selenide. For specific X-ray diffraction results, see figure 2 , the transmission energy spectrum results are shown in Figure 7 .

Embodiment 3

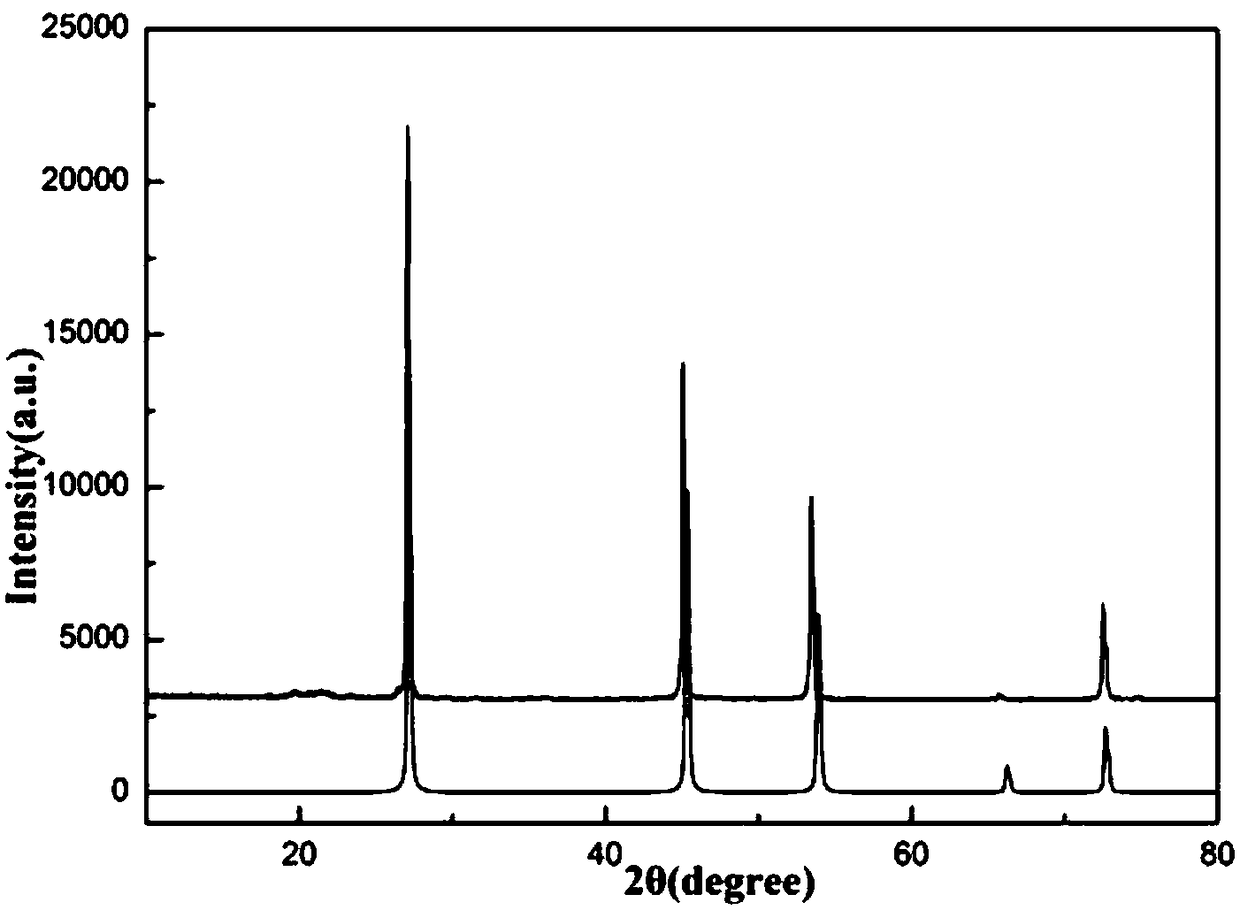

[0032] Using the same raw materials as in Example 1, mixed according to the molar ratio of 1:1, the powder sample was pressed and formed using the same assembly as in Example 1, the synthesis pressure was 3.0GPa, the synthesis temperature was 1500K, and the holding time was 30 minutes. After the heating was stopped, the sample was naturally cooled to room temperature and then the pressure was released. Under this condition, zinc selenide with higher purity was synthesized. For specific X-ray diffraction results, see image 3 , the transmission energy spectrum results are shown in Figure 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com