Preparation method and application of segmented copolymer semiconductor nanowire with spiral structure

A technology of block copolymers and helical structures, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, nanotechnology for materials and surface science, etc., can solve the problems of high difficulty in preparation, control of nanowires, and no gas sensing applications and other problems, to achieve the effect of low requirements on equipment and process conditions, good repeatability, and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment prepares PPI (-DMAENBA)-b-P3HT nanowire and organic field effect transistor sensor based on it as follows:

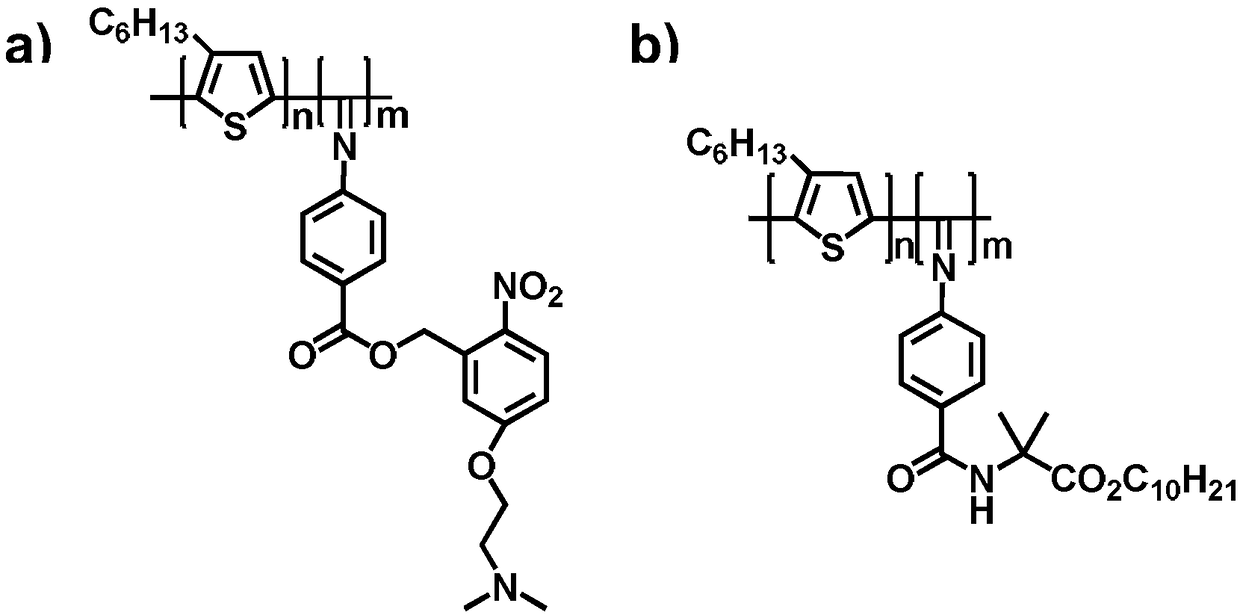

[0038] (1) PPI(-DMAENBA)-b-P3HT is dissolved in o-dichlorobenzene to form a solution A with a concentration of 2mg / mL, and PMMA is dissolved in chlorobenzene to form a solution B with a concentration of 130mg / mL; Mix well with solution B to form a blend solution, in which the mass ratio of PPI(-DMAENBA)-b-P3HT to PMMA is 1:80, or 1:60, or 1:40. The molecular structural formulas of PPI(-DMAENBA)-b-P3HT and PPI-b-P3HT are as follows figure 1shown.

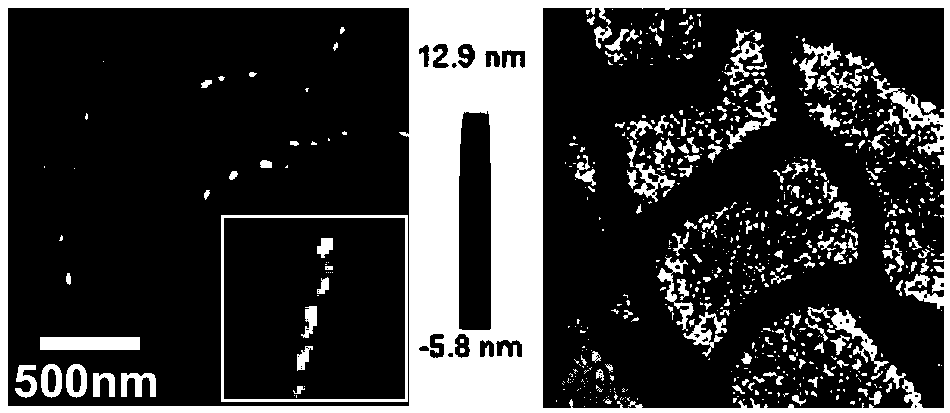

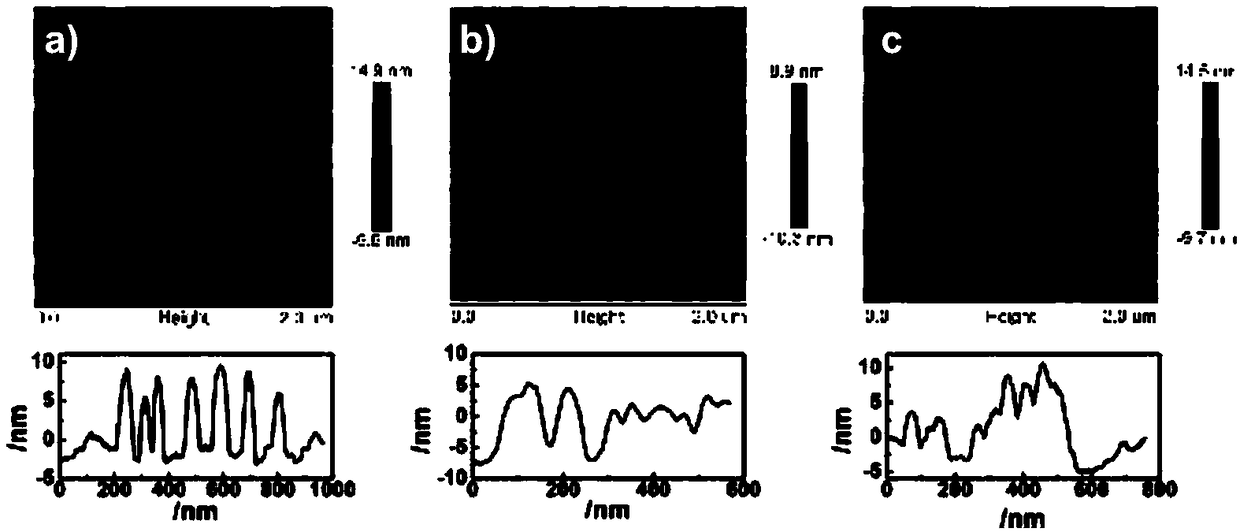

[0039] (2) The n-type silicon wafer is cleaned as a substrate after being heated in a concentrated sulfuric acid-hydrogen peroxide mixed solution; by the spin coating method, the blended solution is spin-coated on the substrate at a speed of 2000 rpm and vacuum-dried at room temperature for 12 hours, thereby On the substrate, a double-layer film with PMMA film as the bottom layer and PPI(-DMAENB...

Embodiment 2

[0048] In this embodiment, helical structure nanowires and organic field effect transistor sensors based on the same method as in Example 1 were prepared, the only difference being that PPI(-DMAENBA)-b-P3HT was replaced with PPI-b-P3HT. The properties of the obtained helical nanowires and sensors are similar to those of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com