Algae inhibitor, method for producing algae inhibitor and algae inhibition method

A manufacturing method and inhibitor technology, applied in the direction of herbicides and algicides, botany equipment and methods, chemicals for biological control, etc., can solve the problems of insufficient inhibition of algae, achieve efficient use, high solubility High, the effect of inhibiting algae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] Regarding the preparation of the binder, the "natural product-derived polymer" and the "non-environmental polluting substance" are preferably prepared by dispersing or dissolving them in water in a slurry state.

[0082] In addition, when the "non-environmental pollutant" and the gelling agent are used together, it is preferable that the gelling agent is also prepared in advance as an aqueous solution (or fine dispersion) and then mixed with each other.

[0083] In either case, it is preferred to dry it afterwards, and if it does not form granules or flakes (if necessary), it is pulverized to make it into granules or flakes after drying, and the obtained material is used as a core agent (or core agent ingredients).

[0084] From the viewpoint of enclosing the medicinal ingredient inside the core dosage form and allowing the medicinal ingredient present inside the core dosage form to be released slowly, it is preferable to dissolve the medicinal ingredient in "natural pr...

Embodiment 1

[0127] [Research on core agent]

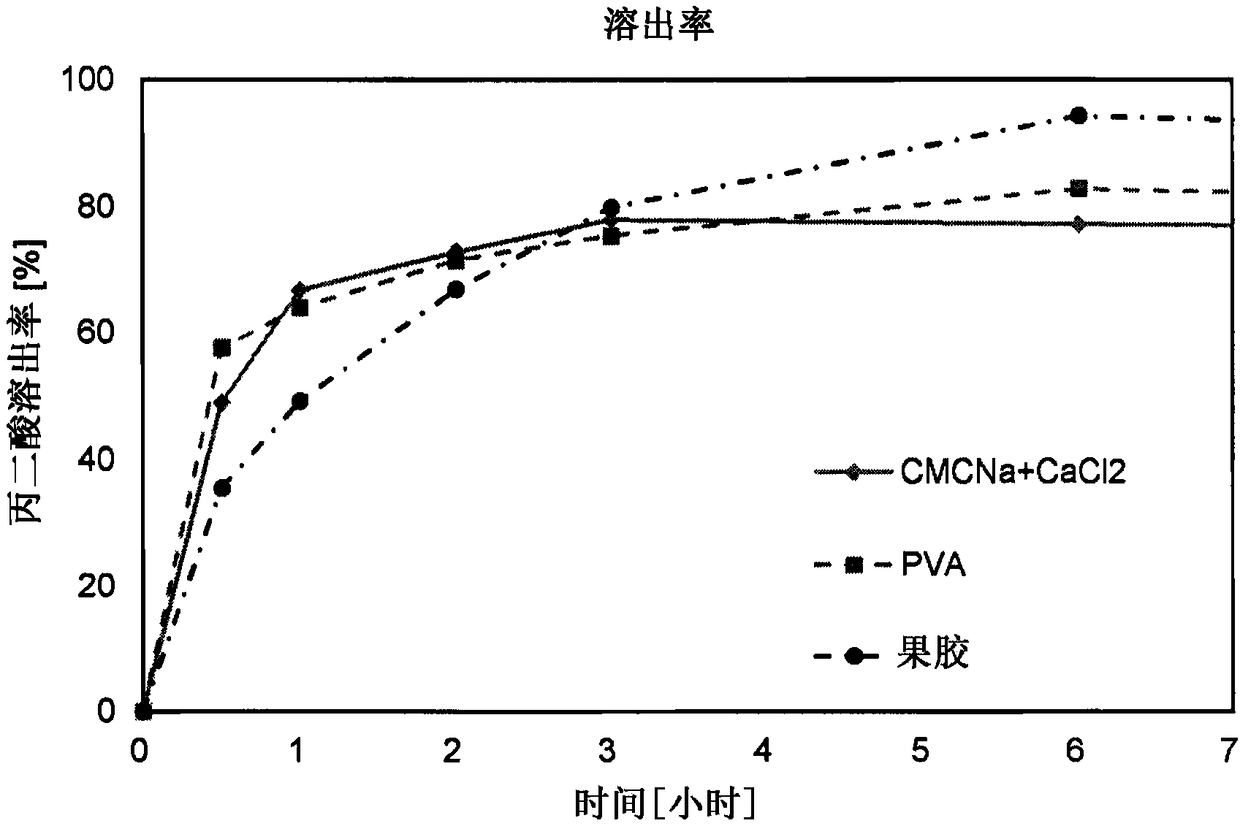

[0128] Add the following various binders to the active ingredient consisting of lysine hydrochloride and malonic acid to make an algae inhibitor. As "non-environmental polluting substances", sodium carboxymethyl cellulose (CMCNa) as a salt of carboxymethyl cellulose is used; calcium chloride (CaCl 2 ); As the "polymer derived from natural products", the core agent was made using pectin, which is a polysaccharide, and polyvinyl alcohol (PVA) which is neither "polymer derived from natural products" nor "non-environmental pollutant". Research.

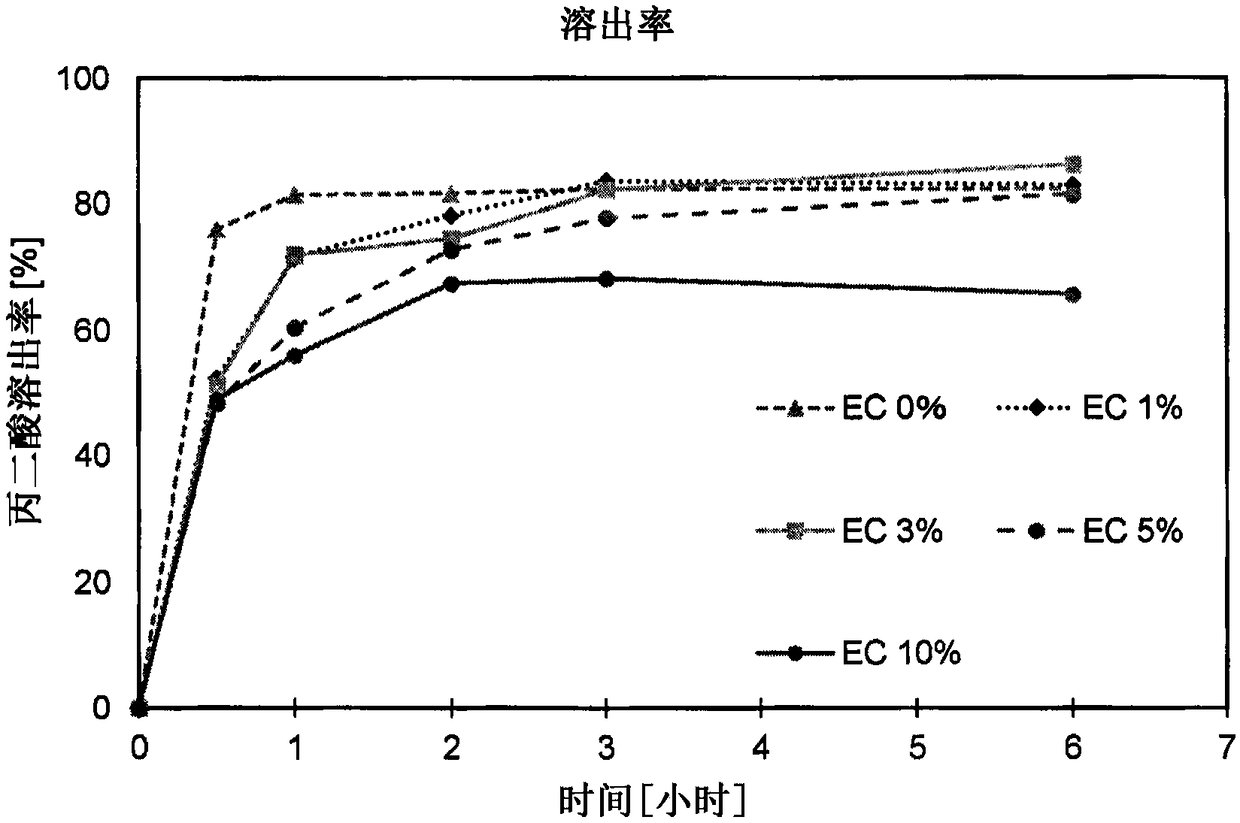

[0129] The composition of the algae inhibitor contained 35% by mass of lysine hydrochloride, 35% by mass of malonic acid, 28% by mass of the binder, and 1% by mass of the coating agent based on the entire algae inhibitor.

[0130] As a coating agent, ethylcellulose (EC) was used.

[0131] Lysine hydrochloride and malonic acid are mixed, and carboxymethylcellulose sodium (CMCNa) and calcium chloride (Ca...

Embodiment 2

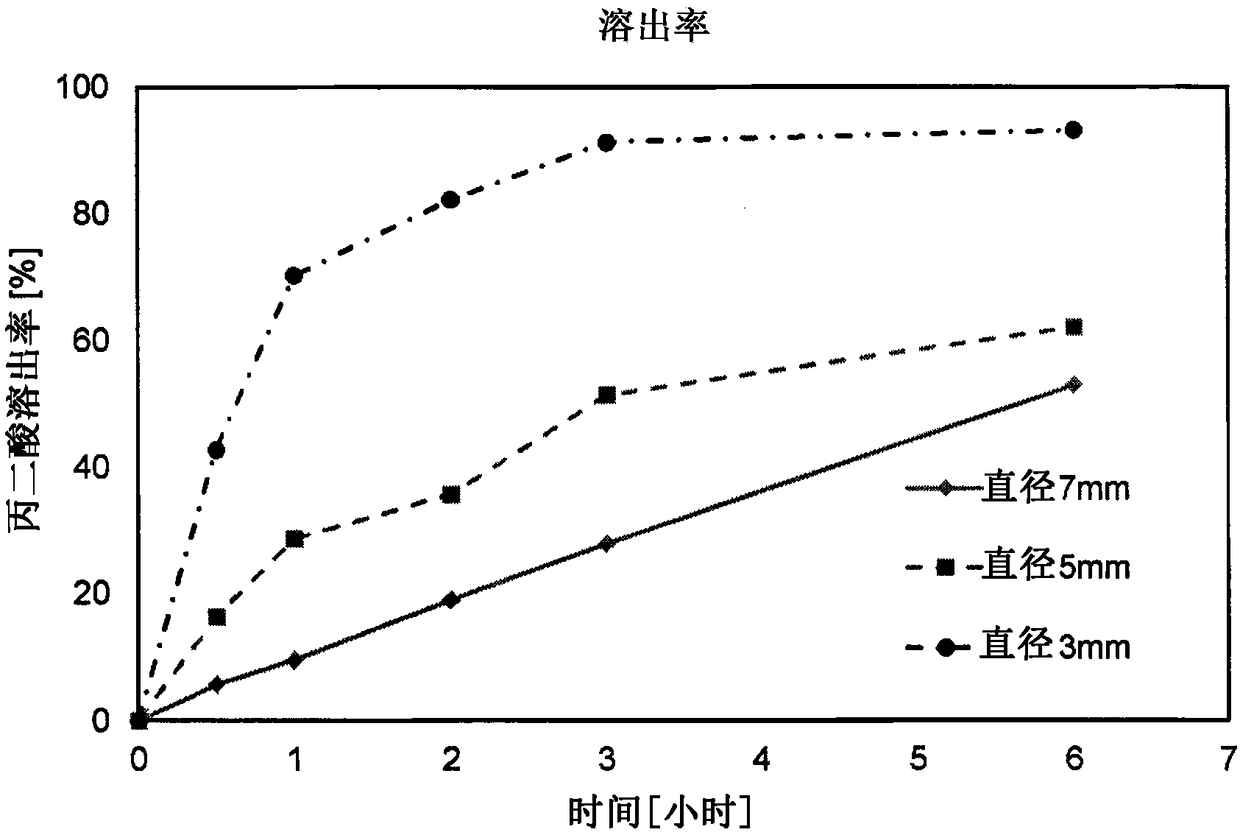

[0144] [Research on particle size of algae inhibitor]

[0145] Next, the algae inhibitor was made into granules, and the change in the dissolution rate of the medicinal ingredient was studied when the particle size was changed.

[0146] CMCNa and calcium chloride were added to lysine hydrochloride and malonic acid and granulated, and the granulated flaky drug was coated with EC as a coating agent to produce an algae inhibitor. Regarding the composition of the algae inhibitor, 34% by mass of lysine hydrochloride, 34% by mass of malonate, 15% by mass of CMCNa, 15% by mass of calcium chloride, and 1% by mass of the entire algae inhibitor % by mass, moisture content is 1% by mass.

[0147] In addition, algae inhibitors with particle diameters of about 7 mm, 5 mm, and 3 mm were prepared.

[0148] And, the dissolution rate of malonic acid per hour was measured by the same procedure and method as in Example 1.

[0149] The results are shown in figure 2 . The larger the particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com