A kind of paint with formaldehyde purification function and preparation method thereof

A formaldehyde purification and functional technology, applied in the field of air purification, can solve problems such as unsatisfactory formaldehyde removal effect, inability to achieve elimination, and inability to continue, so as to eliminate the risk of secondary pollution, enhance the ability to remove formaldehyde, and the preparation process. Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

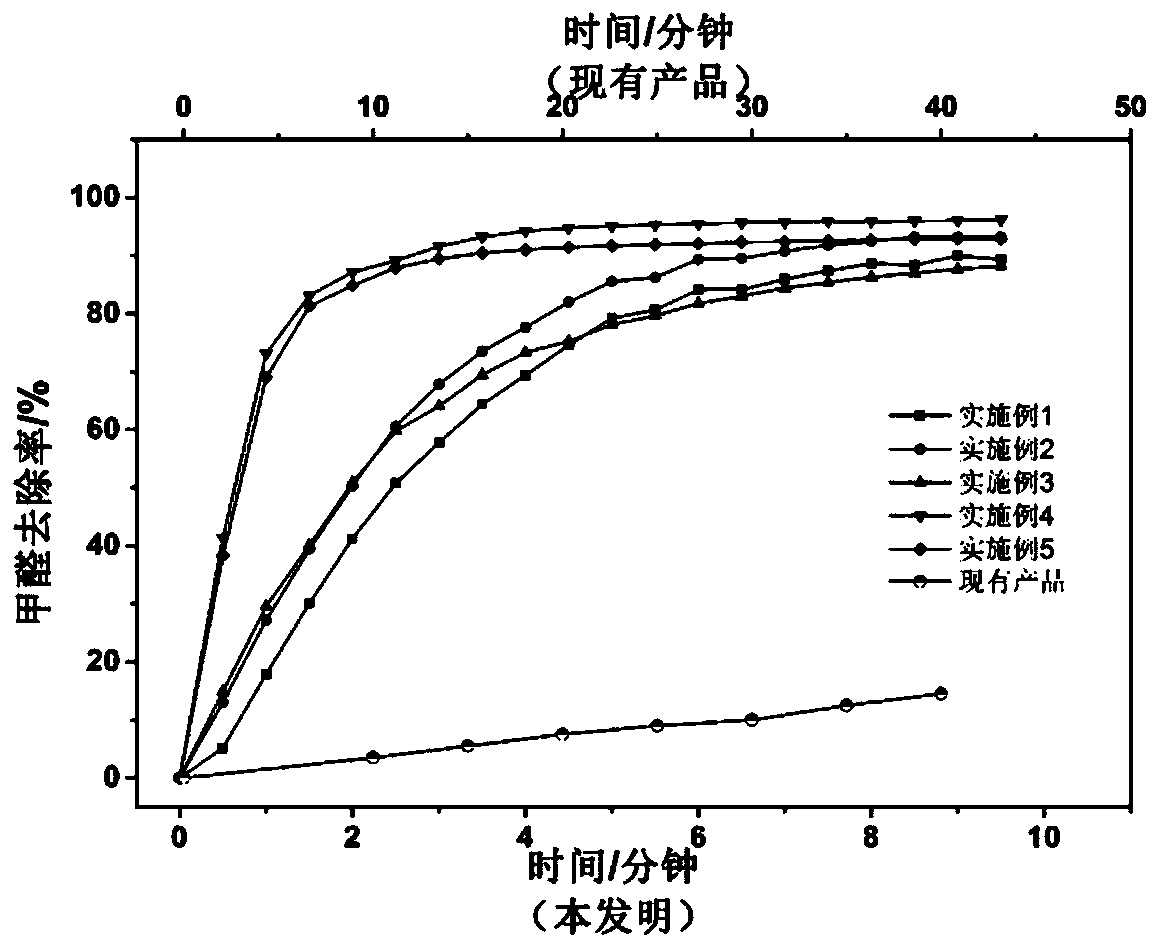

[0032] Embodiment 1: Preparation of coating with formaldehyde purification function.

[0033] 1) Add 1g of polyvinylpyrrolidone to 500g of deionized water, stir mechanically at 80°C to dissolve the polyvinylpyrrolidone, then add 1g of polyacrylamide, continue stirring at constant temperature to dissolve the polyacrylamide, and obtain solution A;

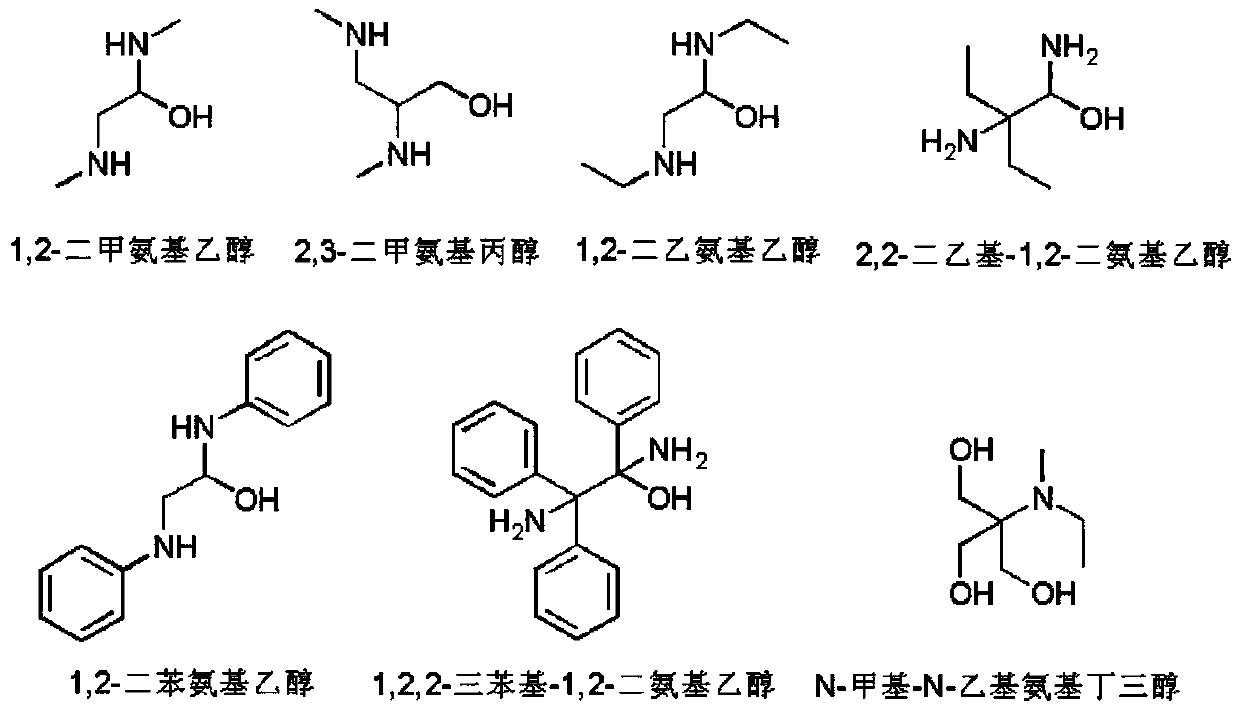

[0034] 2) Mix 1g of titanium dioxide, 1g of tin dioxide, 1g of silicon dioxide, 2g of magnesium oxide, 1g of activated carbon, 1g of sodium carbonate and 4g of 1,2-dimethylaminoethanol to obtain mixture B;

[0035]3) Add the mixture B obtained in step 2) to the solution A obtained in step 1), and disperse evenly by means of mechanical stirring to obtain mixture C, which is filtered through a 200-mesh filter to obtain a formaldehyde scavenger;

[0036] 4) Add the formaldehyde scavenger obtained in step 3) to 1.8kg of water-based silicone acrylic resin, disperse at a speed of 1500rpm, add 30g of emulsified silicone oil during the dispe...

Embodiment 2

[0037] Embodiment 2: Preparation of coating with formaldehyde purification function.

[0038] 1) Add 13g of polyvinylpyrrolidone into 6.5kg of absolute ethanol, stir mechanically at 60°C to dissolve the polyvinylpyrrolidone, then add 10g of polyethylene oxide, and continue stirring at constant temperature to dissolve the polyethylene oxide to obtain solution A;

[0039] 2) Mix 7g of titanium dioxide, 6g of tin dioxide, 5g of silicon dioxide, 6g of magnesium oxide, 13g of activated carbon, 9g of sodium bicarbonate and 42g of 1,2-diethylaminoethanol to obtain mixture B;

[0040] 3) Add the mixture B obtained in step 2) to the solution A obtained in step 1), and disperse evenly by means of mechanical stirring to obtain mixture C, which is filtered through a 300-mesh filter to obtain a formaldehyde scavenger;

[0041] 4) Add the formaldehyde scavenger obtained in step 3) to 5.5kg of water-based acrylic resin, disperse at a speed of 1000rpm, add 400g of polydimethylsiloxane during ...

Embodiment 3

[0042] Embodiment 3: Preparation of coating with formaldehyde purification function.

[0043] 1) Add 2g of polyvinylpyrrolidone into 1.6kg of deionized water, stir magnetically at 25°C to dissolve the polyvinylpyrrolidone, then add 2g of polymethacrylic acid, and continue stirring at a constant temperature to dissolve the polymethacrylic acid to obtain solution A;

[0044] 2) Mix 4g of titanium dioxide, 4g of tin dioxide, 4g of silicon dioxide, 3g of magnesium oxide, 3g of activated carbon, 2g of sodium sulfite and 10g of 1,2,2-triphenyl-1,2-diaminoethanol to obtain mixture B;

[0045] 3) Add the mixture B obtained in step 2) to the solution A obtained in step 1), and disperse evenly by means of magnetic stirring to obtain mixture C, which is filtered through a 200-mesh filter to obtain a formaldehyde scavenger;

[0046] 4) Add the formaldehyde scavenger obtained in step 3) to 5kg of water-based epoxy resin, disperse at a speed of 1200rpm, add 25g of polyoxypropylene glyceryl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com