Preparation and application of double-metal phosphide and carbon nanotube composite material

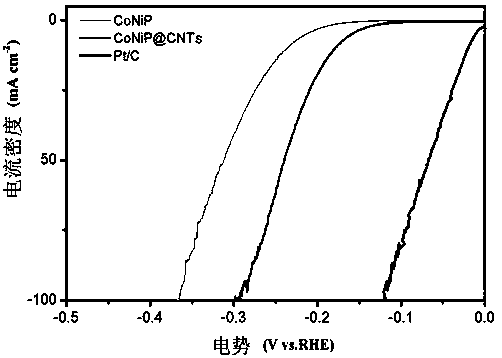

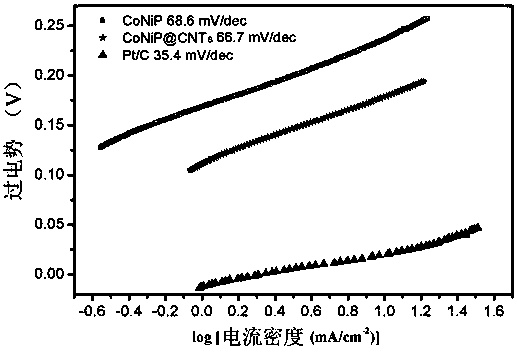

A carbon nanotube and composite material technology, which is applied in the field of preparation of bimetallic phosphide carbon nanotube composite materials, can solve the problems of difficult preparation, carbon nanotubes cannot be phosphide phase composite, etc., and achieves good application prospects and good electrochemical performance. Effects of stability and catalytic activity, good hydrogen evolution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Treatment of carbon nanotubes: Take 1-3 g of multi-walled carbon nanotubes and put them in a round bottom flask, add 50-120 mL of concentrated nitric acid. Then condense and reflux for 5 hours in a collector-type constant temperature heating magnetic stirrer, and the temperature is controlled at 120°C. The obtained product was washed with deionized water, dried at 60°C, and set aside;

[0030] (2) Preparation of CoNiP@CNTs material: Weigh Co(NO 3 ) 2 ·6H 2 O and Ni(NO 3 ) 2 ·6H 2O each 0.3g, put into a beaker, then add 15ml of water, and magnetically stir for 15min to make it fully dissolved; then add 0.01g of the carbon nanotubes treated above, ultrasonically until the carbon nanotubes are dispersed; then add 0.31g of white phosphorus, 5ml The ethanol was stirred evenly and put into the reaction kettle, and the reaction kettle was put into a constant temperature drying oven, and hydrothermally reacted at 200°C for 20h. After the completion of the hydrotherma...

Embodiment 2

[0033] (1) Treatment of carbon nanotubes: same as in Example 1;

[0034] (2) Preparation of CoNiP@CNTs material: Take 0.4g of white phosphorus in a beaker, add 15 ml of water and heat until the white phosphorus melts; then add 0.02g of the treated carbon nanotubes, stir for 15 minutes to mix the white phosphorus and carbon nanotubes uniform. Weigh Co(NO 3 ) 2 ·6H 2 O and Ni(NO 3 ) 2 ·6H 2 O each 0.2g, put into another beaker, add 10ml ethylene glycol, stir until completely dissolved; then mix the solutions in the two beakers and stir for 10 min, then put into the reaction kettle and put the reaction kettle into a constant temperature In a dry box, hydrothermally react at 200°C for 24h. After the hydrothermal treatment, the solution was vacuum filtered with circulating water, and the product was washed twice with ether and water respectively. The washed material is dried in a vacuum freeze-drying oven, and then ground to obtain CoNiP@CNTs material;

[0035] (3) Hydroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com