Carbon-metal oxide composite coated lithium battery ternary positive electrode material and preparation method thereof, and lithium battery

A positive electrode material and oxide technology, which is applied in battery electrodes, electrical components, secondary batteries, etc., can solve problems affecting electrochemical activity, improve electronic conductivity and ion diffusion coefficient, increase electronic conductivity, and reduce side effects. The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028]In another typical embodiment of the present application, a method for preparing a carbon-metal oxide composite-coated lithium battery ternary positive electrode material is provided, the preparation method comprising: mixing MOFs with a ternary positive electrode material matrix, A mixture is formed; in a nitrogen atmosphere or an inert atmosphere, the mixture is sintered at 300-800° C. to obtain a carbon-metal oxide composite-coated lithium battery ternary cathode material. Furthermore, the above-mentioned sintering temperature is preferably 600-750°C.

[0029] MOFs (Metal-Organic Frameworks, metal-organic framework materials) are organic-inorganic hybrid materials with intramolecular pores formed by the self-assembly of organic ligands and metal ions or clusters through coordination bonds. MOFs-derived hybrid micro-nanostructures exhibit enhanced performance compared to their respective counterparts due to the synergistic effect between different components, which is ...

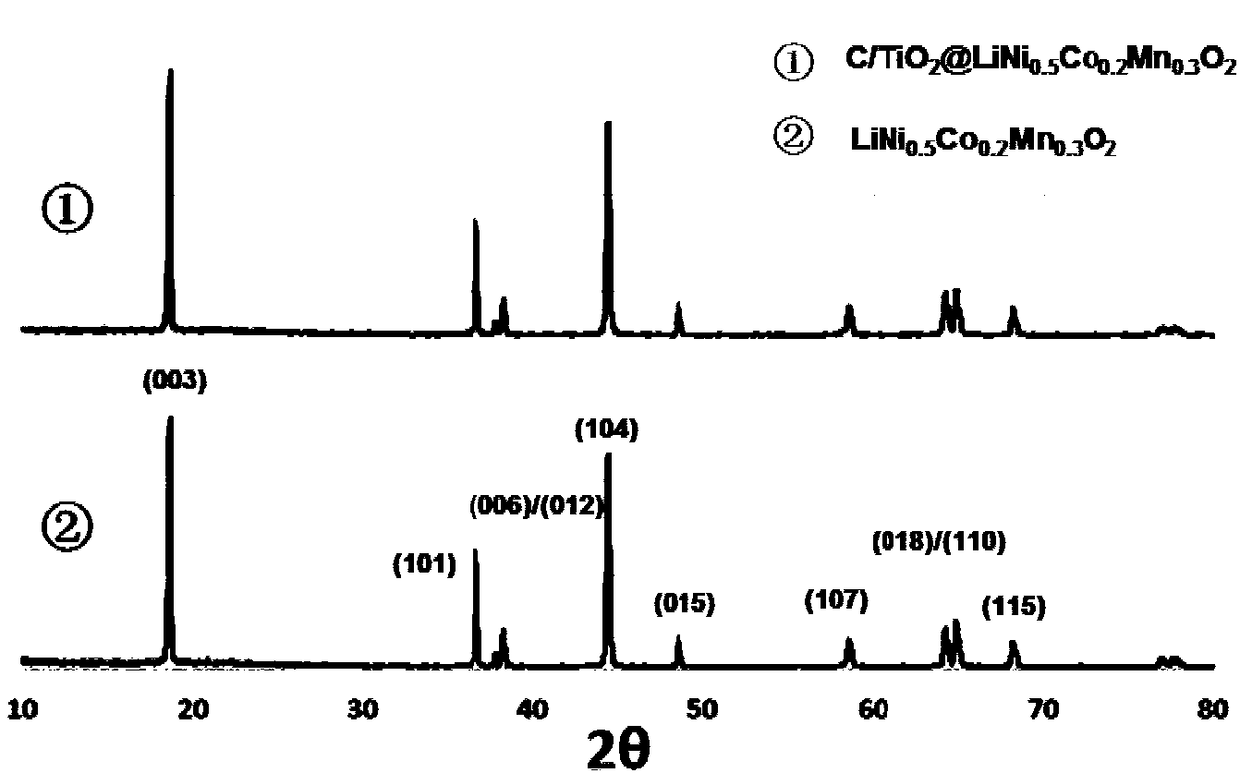

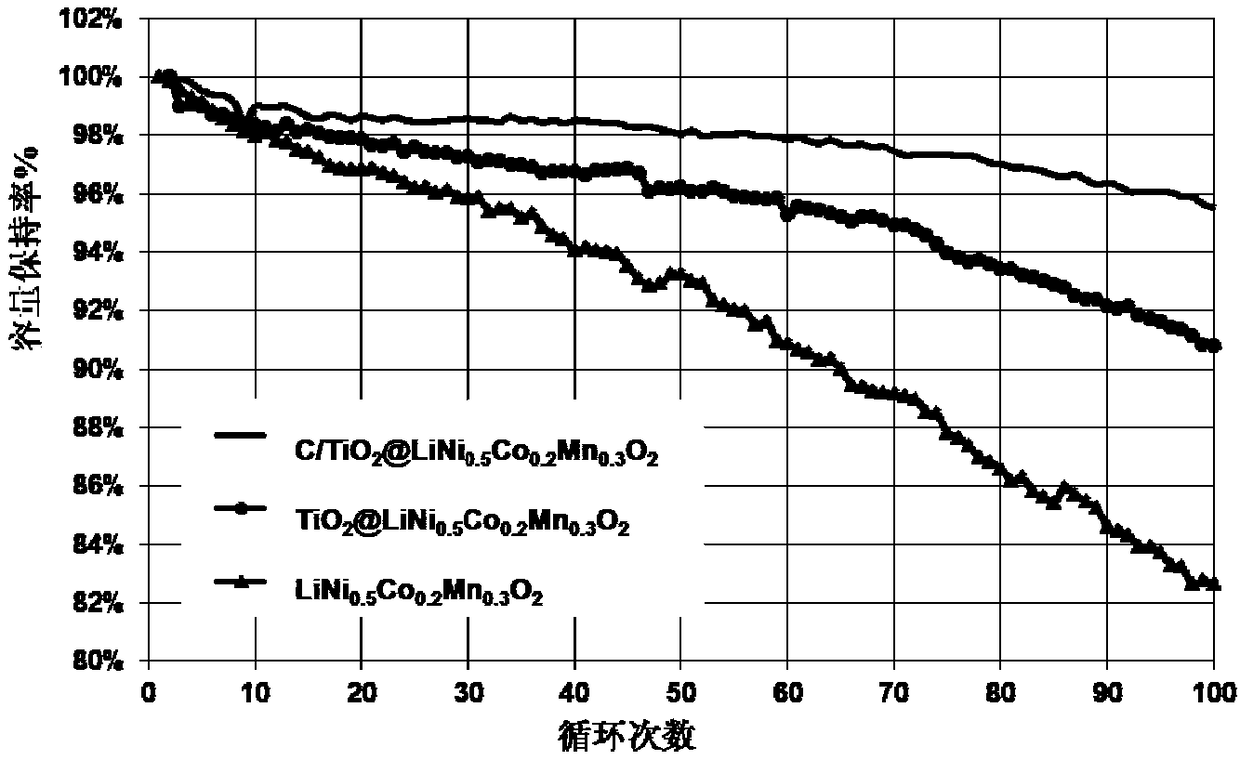

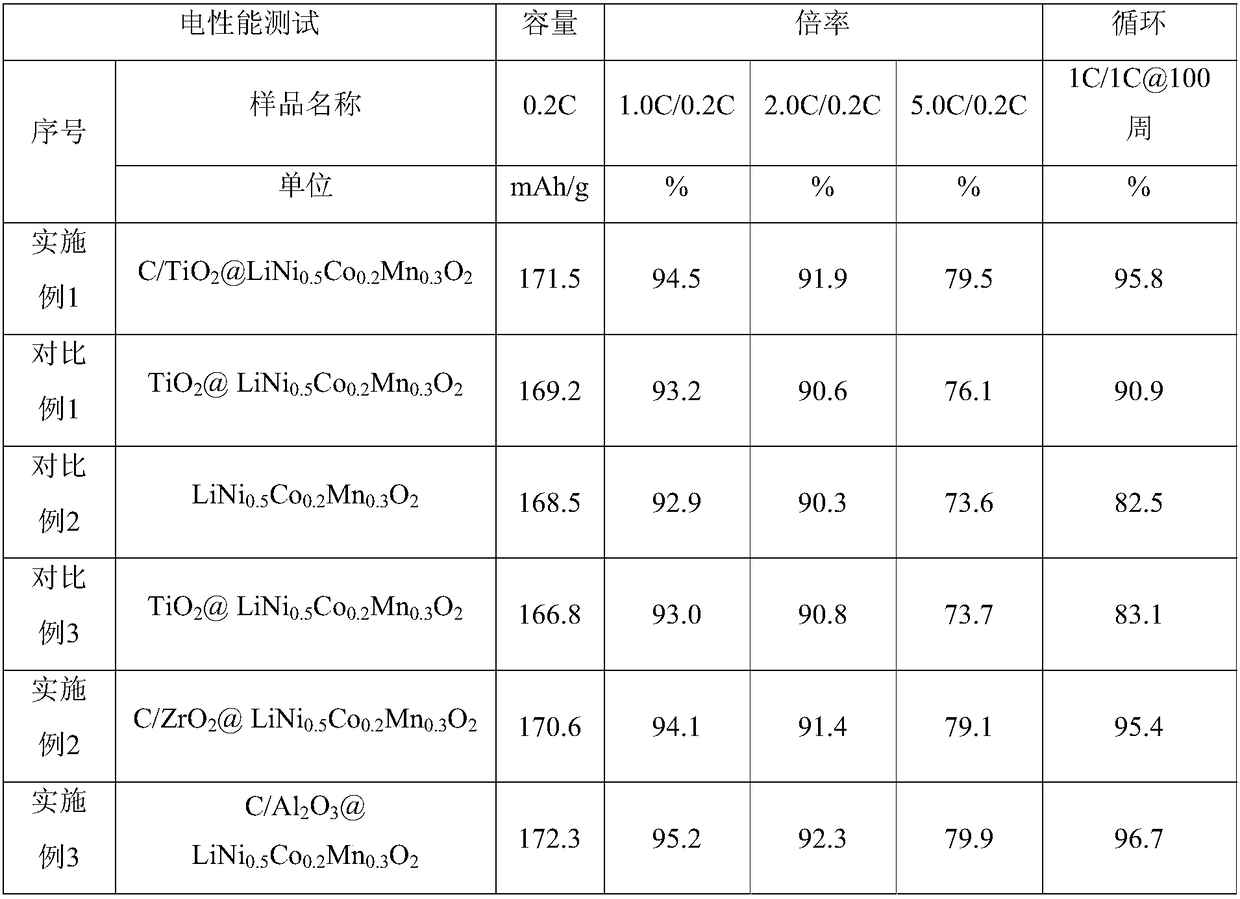

Embodiment 1

[0044] Preparation of Precursor Ni by Hydroxide Co-precipitation 0.5 co 0.2 mn 0.3 (OH) 2 , and then combine the precursor with Li 2 CO 3 Mix evenly according to the molar ratio of Li to metal 1:1.05, sinter at 950°C for 10 hours in an air atmosphere, crush, and pass through a 300-mesh sieve to obtain LiNi 0.5 co 0.2 mn 0.3 o 2 .

[0045] Preparation of Ti-MIL-125 by solvothermal method: dissolve the organic ligand phthalic acid in a mixed solvent of DMF and methanol, and mix it uniformly by ultrasonic to obtain a transparent mixed solution, add tetrabutyl titanate to the mixed solution, and continue to mix evenly by ultrasonic After that, it was added to a polytetrafluoroethylene-lined stainless steel reactor at 150°C for 48 hours, solid-liquid separation, washing, and drying in a vacuum oven at 50°C for 24 hours to obtain carbon and metal Ti oxide precursor Ti-MIL-125.

[0046] According to metal oxide and LiNi 0.5 co 0.2 mn 0.3 o 2 The mass ratio of 2.0%: 1 wei...

Embodiment 2

[0057] Preparation of Precursor Ni by Hydroxide Co-precipitation 0.5 co 0.2 mn 0.3 (OH) 2 , and then the precursor with Li 2 CO 3 Mix evenly according to the molar ratio of Li to metal 1:1.05, sinter at 950°C for 10 hours in an air atmosphere, crush, and pass through a 300-mesh sieve to obtain LiNi 0.5 co 0.2 mn 0.3 o 2 .

[0058] Solvothermal preparation of UiO-66: 1,4-phthalic acid (H 2 BDC) and ZrCl 4 Dissolve in DMF at room temperature, mix evenly and seal to obtain a mixed solution, add the above mixed solution into a polytetrafluoroethylene-lined stainless steel reactor at 120°C for 24 hours, separate the solid from the liquid, wash the solid with DMF, and then dry the solid at room temperature. The carbon and metal Zr oxide precursor UiO-66 was obtained.

[0059] According to the same sequence as in Example 1, the mass ratio of the metal oxide to the metal oxide was 2.0%: 1 and the above-mentioned UiO-66 and LiNi 0.5 co 0.2 mn 0.3 o 2 Add deionized water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com