Nitrogen and phosphorus co-doped carbon coated MoO3-x and preparation method thereof

A co-doping, carbon-coated technology, applied in active material electrodes, electrical components, electrochemical generators, etc., can solve the problem that electrospinning cannot be mass-produced, the preparation of spinning slurry is complicated, and the electrochemical stability is insufficient. problems, to achieve the effect of loose experimental conditions, improved purity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention relates to a nitrogen-phosphorus co-doped carbon-coated MoO 3-x The preparation method comprises the following steps:

[0026] (1) Add phosphomolybdic acid to deionized water, and stir evenly to obtain a phosphomolybdic acid solution with a concentration of 1 to 2.5 mg / ml;

[0027] (2) Add N-methylimidazole to the phosphomolybdic acid solution, the molar ratio of the added N-methylimidazole to step (1) phosphomolybdic acid is 3:1, stir for 7-12h, and obtain a yellow precipitate;

[0028] (3) After the yellow precipitate of step (2) is centrifuged to obtain the separated product, the separated product is washed 3-5 times to remove impurities with a mixed solution of hexanaphthene and ethanol, and the reaction product is obtained, wherein the mixture of hexanaphthene and ethanol is The volume ratio is (2-5):1.

[0029] (4) Vacuum drying the reaction product obtained in step (3) for 7-10 hours at a drying temperature of 40-70° C. to obtain a dry product.

...

Embodiment 1

[0033] 1) Add 100 mg of phosphomolybdic acid to 40 mL of deionized water, and stir evenly to obtain a phosphomolybdic acid solution with a concentration of 2.5 mg / mL;

[0034] 2) Add 12.4 mg of N-methylimidazole to the phosphomolybdic acid solution, stir for 7 hours, and obtain a yellow precipitate;

[0035] 3) centrifuging the yellow precipitate to obtain a centrifuged product, washing the centrifuged product 3 times with a mixed solution of cyclohexane and ethanol to remove impurities, and obtaining a reaction product; wherein the volume ratio of cyclohexane and ethanol is 3:1;

[0036] 4) vacuum drying the reaction product obtained in step 3) at 50° C. for 7 hours to obtain a dried product;

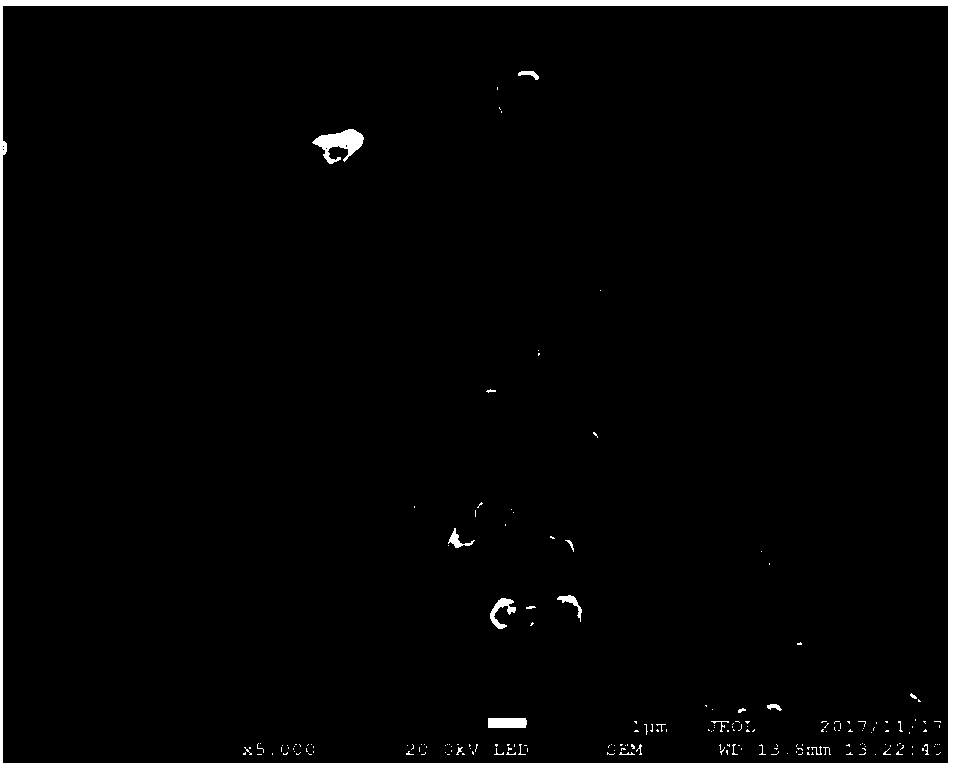

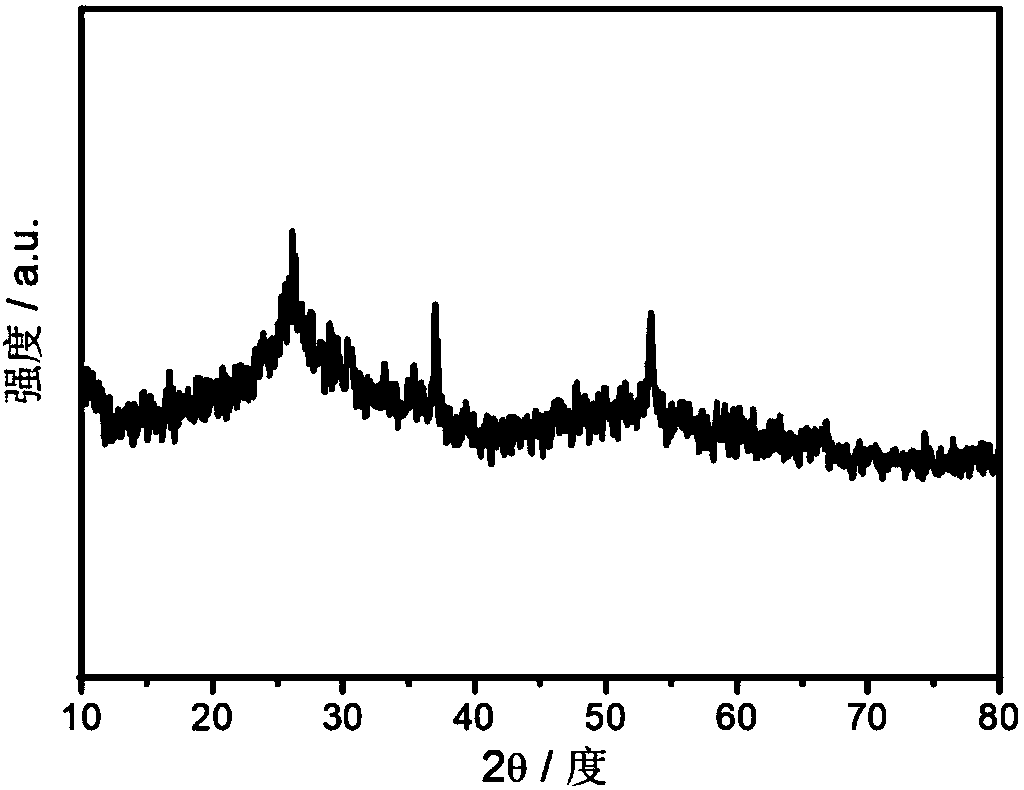

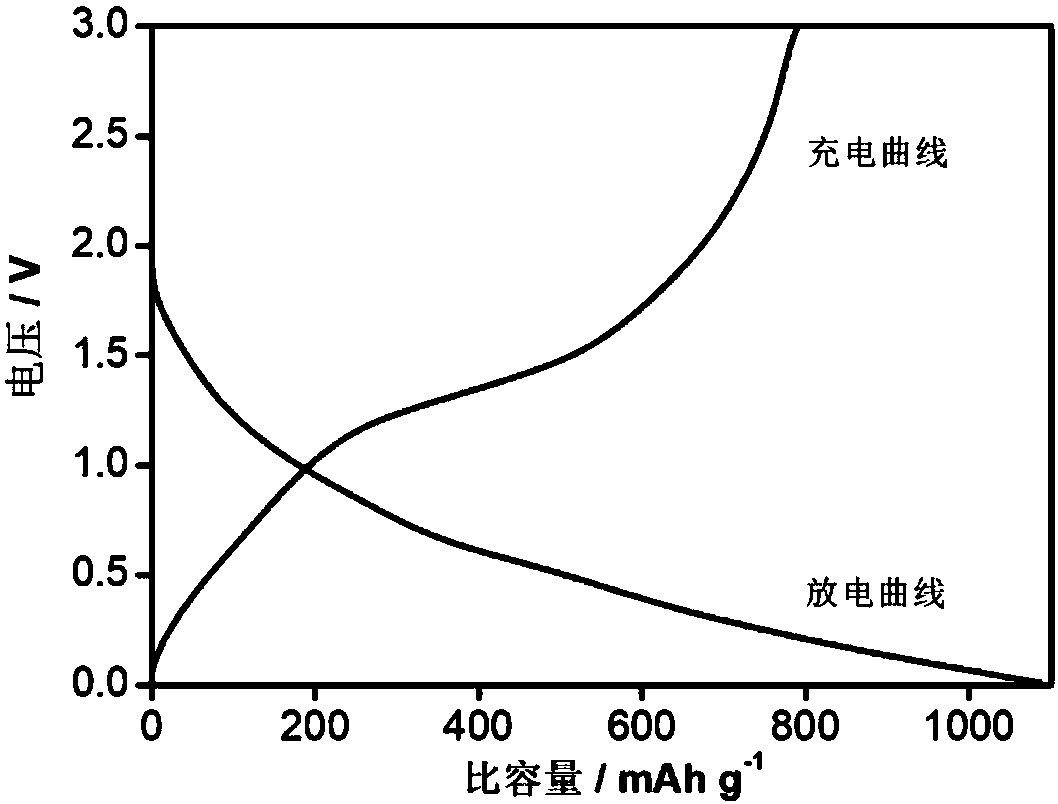

[0037] 5) Calcining the dried product of step 4) in an argon atmosphere for 2 hours at a calcination temperature of 400°C to obtain nitrogen and phosphorus co-doped carbon-coated MoO 3-x nanomaterials.

[0038] Nitrogen and phosphorus co-doped carbon-coated MoO prepared by the data o...

Embodiment 2

[0040] 1) Add 100 mg of phosphomolybdic acid to 50 mL of deionized water, and stir evenly to obtain a phosphomolybdic acid solution with a concentration of 2 mg / mL;

[0041] 2) Add 12.4 mg of N-methylimidazole to the phosphomolybdic acid solution, stir for 12 hours, and obtain a yellow precipitate;

[0042] 3) centrifuging the yellow precipitate to obtain a centrifuged product, washing the centrifuged product 5 times with a mixed solution of cyclohexane and ethanol to remove impurities, and obtaining a reaction product; wherein the volume ratio of cyclohexane and ethanol is 3:1;

[0043] 4) vacuum drying the reaction product obtained in step 3) at 50° C. for 8 hours to obtain a dry product;

[0044] 5) Calcining the dried product of step 4) in an argon atmosphere for 2 hours at a calcination temperature of 400°C to obtain nitrogen and phosphorus co-doped carbon-coated MoO 3-x nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com