Silk-fibroin multilayer composite micro-needle and preparation method thereof

A silk fibroin, multi-layer composite technology, used in microneedles, needles, other medical devices, etc., to achieve good biocompatibility, no irritation, allergic reactions, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

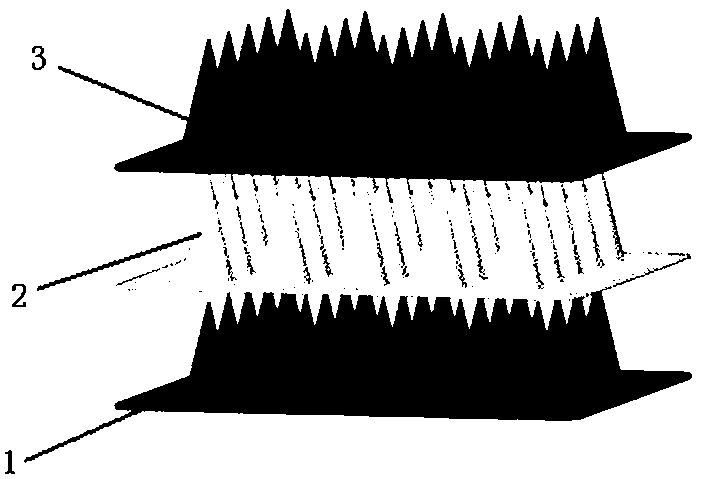

[0025] See attached figure 1 , which is a schematic diagram of a structural decomposition model of a multi-layer composite needle wall microneedle provided in this embodiment; from the inside to the outside, there are microneedle base layer 1, microneedle slow-release intermediate layer 2 and microneedle quick-release shell 3 , the specific steps of its preparation are as follows:

[0026] 1. Preparation of silk fibroin solution: place silkworm silk in a sodium carbonate-sodium bicarbonate buffer solution, treat it at 98-100°C for 30 minutes, then wash it with deionized water, repeat the above operation three times, and perform degumming treatment. The silk fibroin obtained after degumming and drying was dissolved in a 9.3M lithium bromide solution at a bath ratio of 1:10 at 60°C, and dialyzed for three days to obtain a silk fibroin solution.

[0027] 2. Preparation of microneedle base layer: Mix silk fibroin solution and doxorubicin hydrochloride solution at a mass ratio of ...

Embodiment 2

[0033] 1. Preparation of silk fibroin solution: place silkworm silk in sodium carbonate-sodium bicarbonate buffer solution, treat it at 98-100°C for 30 minutes, then wash it with deionized water, repeat the above operation three times for degumming, degumming and drying The dried silk fibroin was dissolved in a 9.3M lithium bromide solution at a bath ratio of 1:10 at 60°C, and dialyzed for three days to obtain a silk fibroin protein solution;

[0034] 2. Preparation of microneedle base layer: Prepare insulin solution, blend silk fibroin solution and insulin solution in step 1 at a mass ratio of 100:1, and apply 3 mg silk fibroin dry weight per 15*15 array on PDMS (polydimethylsiloxane mould) on the mold, after vacuum defoaming under the condition of vacuum degree less than 90 kPa, dry at constant temperature and humidity, temperature 26°C, relative humidity: 59, dry for 21 hours. The dried microneedle sheet was clamped with the tip facing down, immersed in 75 v / v% ethanol for ...

Embodiment 3

[0039] 1. Preparation of silk fibroin solution: place silkworm silk in sodium carbonate-sodium bicarbonate buffer solution, treat it at 98-100°C for 30 minutes, then wash it with deionized water, repeat the above operation three times for degumming, degumming and drying The dried silk fibroin was dissolved in a 9.3M lithium bromide solution at a bath ratio of 1:10 at 60°C, and dialyzed for three days to obtain a silk fibroin protein solution;

[0040] 2. Preparation of the microneedle base layer: Prepare an epidermal growth factor (EGF) solution, blend the silk fibroin solution in step 1 with the EGF solution at a mass ratio of 500:1, and mix 3.1 mg silk fibroin dry weight per 15* 15 arrays were applied on the PDMS (polydimethylsiloxane mold) mold, and after vacuum degassing under the vacuum condition of less than 90 kPa, they were dried at constant temperature and humidity at 24°C, relative humidity: 56%, and dried for 15 hours. The dried microneedle sheet was clamped with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com