Black phosphorene as well as preparation method and application thereof

A technology of black phosphorene and black phosphorus, which is applied in the field of black phosphorene and its preparation, can solve the problems of difficult industrial production, difficult control of crystal size, and low output, and achieve the effects of short time, anti-oxidation, and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

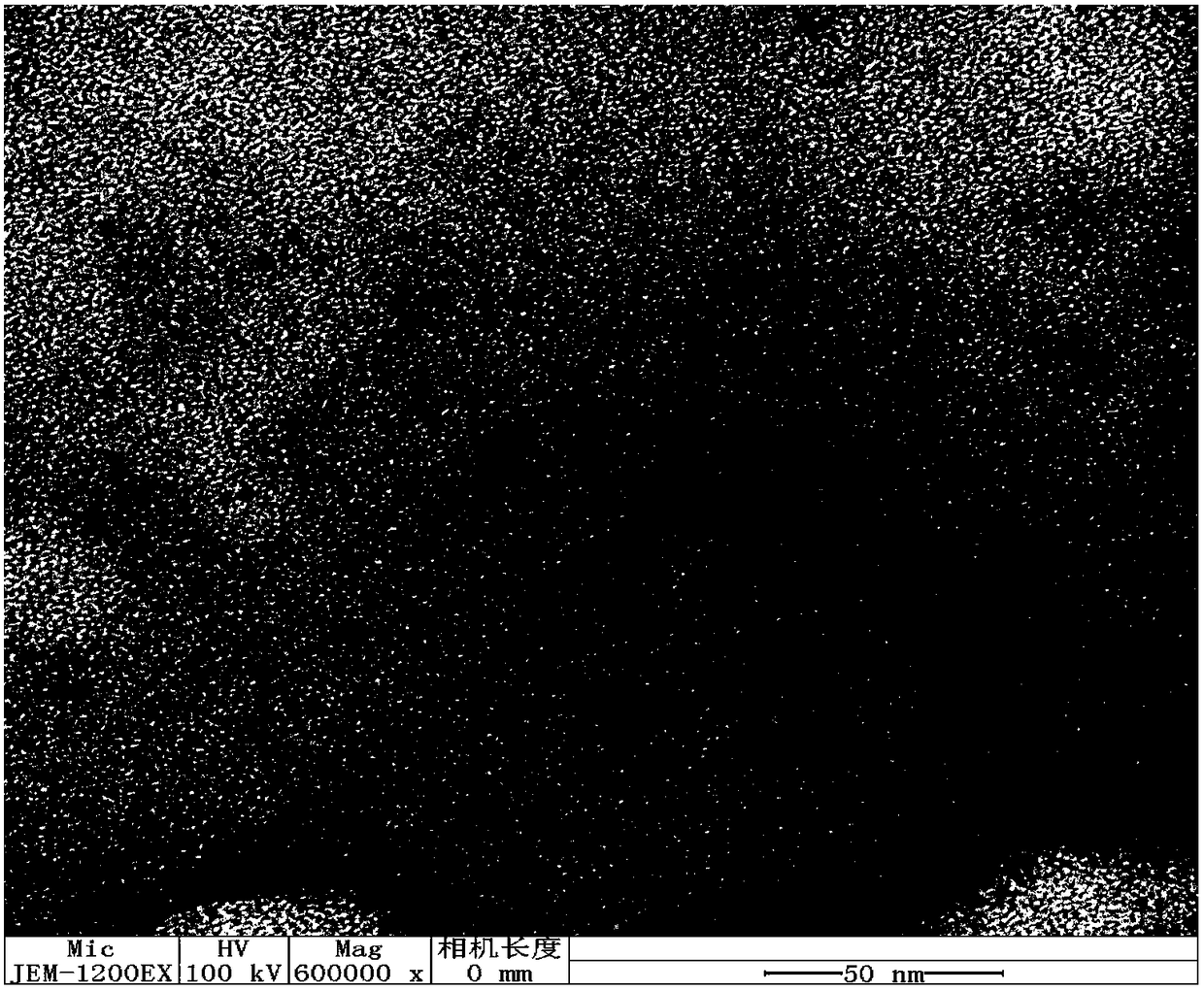

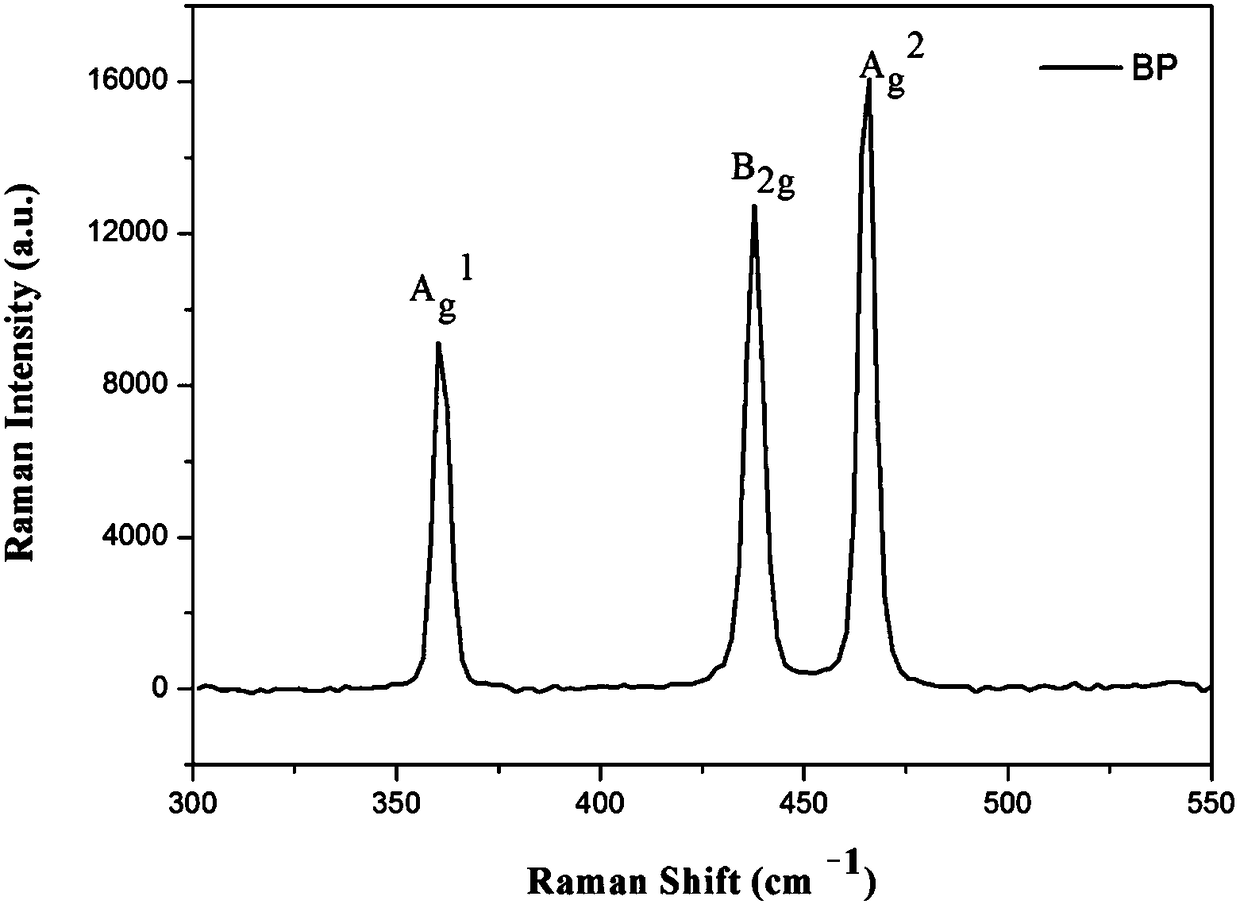

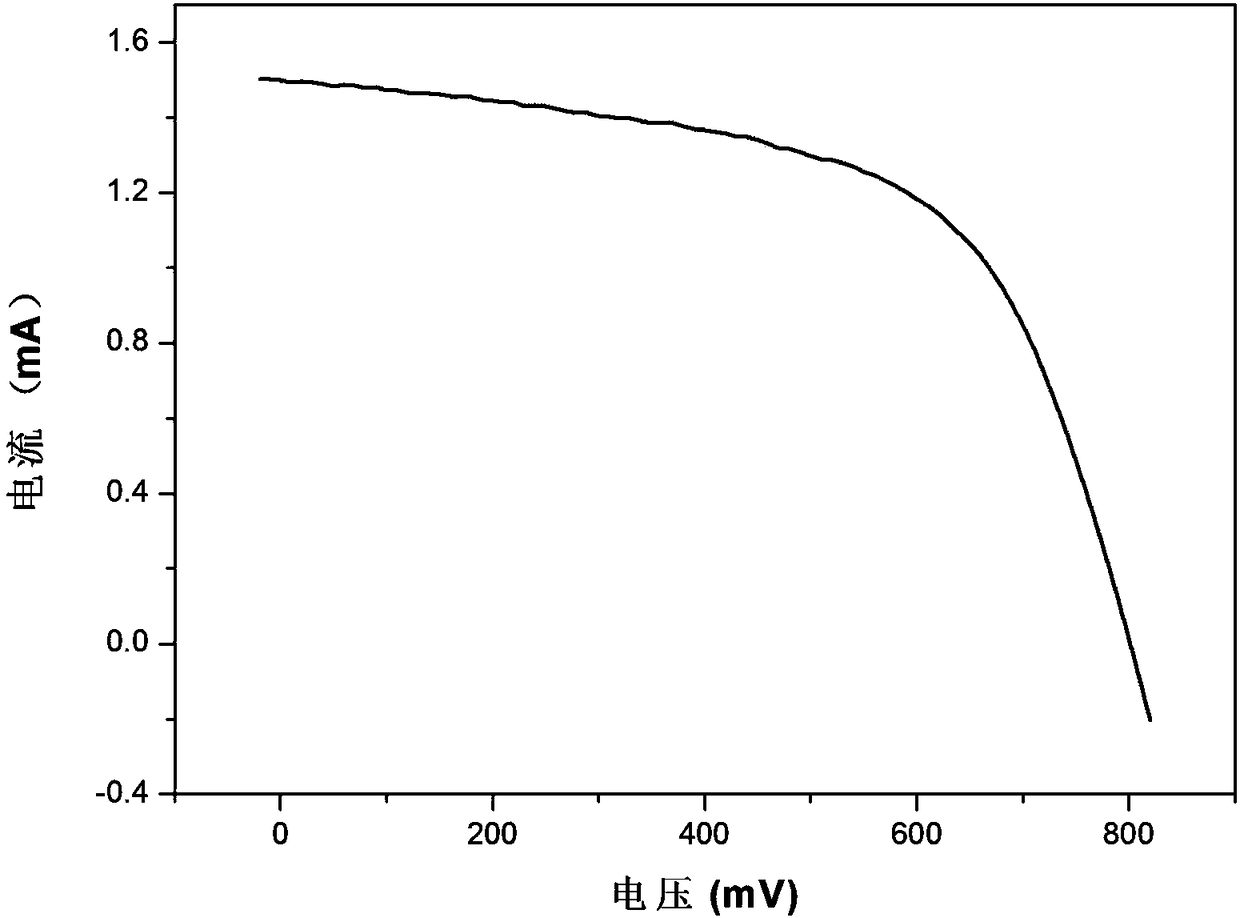

[0030] A preparation method of black phosphorene of the present invention includes the following steps: respectively weighing 5 mg of analytically pure block black phosphorous; placing the weighed sample in a mortar and grinding for 3 minutes, and this process is carried out in a glove box. The ground black phosphorus is dissolved in 15ml of N-methylpyrrolidone. The concentration ratio of the sample to N-methylpyrrolidone is about 1:3. It is placed in the ultrasonic cell crusher. The power of the ultrasonic cell crusher is set to 500W. , The crushing time is 2s, the temperature is 10℃, the working interval is 3s, and the working time is 20min. Start ultrasound. This process should be carried out in the ice field; centrifuge the obtained solution, where the centrifuge speed is 7000r / min, The centrifugation time is 20 minutes and the temperature is 12 degrees; take the supernatant after centrifugation, continue the centrifugation of the obtained supernatant, and continue centrifug...

Embodiment 2

[0034] A preparation method of black phosphorene of the present invention includes the following steps: respectively weighing 4 mg of analytically pure block black phosphorous; placing the weighed sample in a mortar and grinding for 4 minutes, and this process is carried out in a glove box. The ground black phosphorus is dissolved in 14ml of N-methylpyrrolidone, and the concentration ratio of the sample to N-methylpyrrolidone is about 1:3.5. It is placed in the ultrasonic cell crusher, and the power of the ultrasonic cell crusher is 600W. The crushing time is 2s, the temperature is 11℃, the working interval is 3s, and the working time is 25min. Start ultrasound. This process should be carried out in the ice field. Centrifuge the obtained solution, where the centrifuge speed is 7500r / min, The centrifugation time is 20 minutes and the temperature is 12 degrees; take the supernatant after centrifugation, continue the centrifugation of the obtained supernatant, and continue centrifu...

Embodiment 3

[0037] A method for preparing black phosphorene of the present invention includes the following steps: respectively weighing 5 mg of analytically pure block black phosphorous; placing the weighed sample in a mortar and grinding for 5 minutes, and this process is carried out in a glove box. The ground black phosphorus is dissolved in 20ml of N-methylpyrrolidone, and the concentration ratio of the sample to N-methylpyrrolidone is about 1:4. It is placed in the ultrasonic cell crusher, and the power of the ultrasonic cell crusher is 700W. The crushing time is 2s, the temperature is 12℃, the working interval is 3s, and the working time is 20min. Start ultrasound. This process should be carried out in the ice field. Centrifuge the obtained solution, where the centrifuge speed is 8000r / min, The centrifugation time is 20 minutes and the temperature is 12 degrees; take the supernatant after centrifugation, continue centrifuging the supernatant obtained, and continue centrifuging the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com