Silk fibroin hydrogel

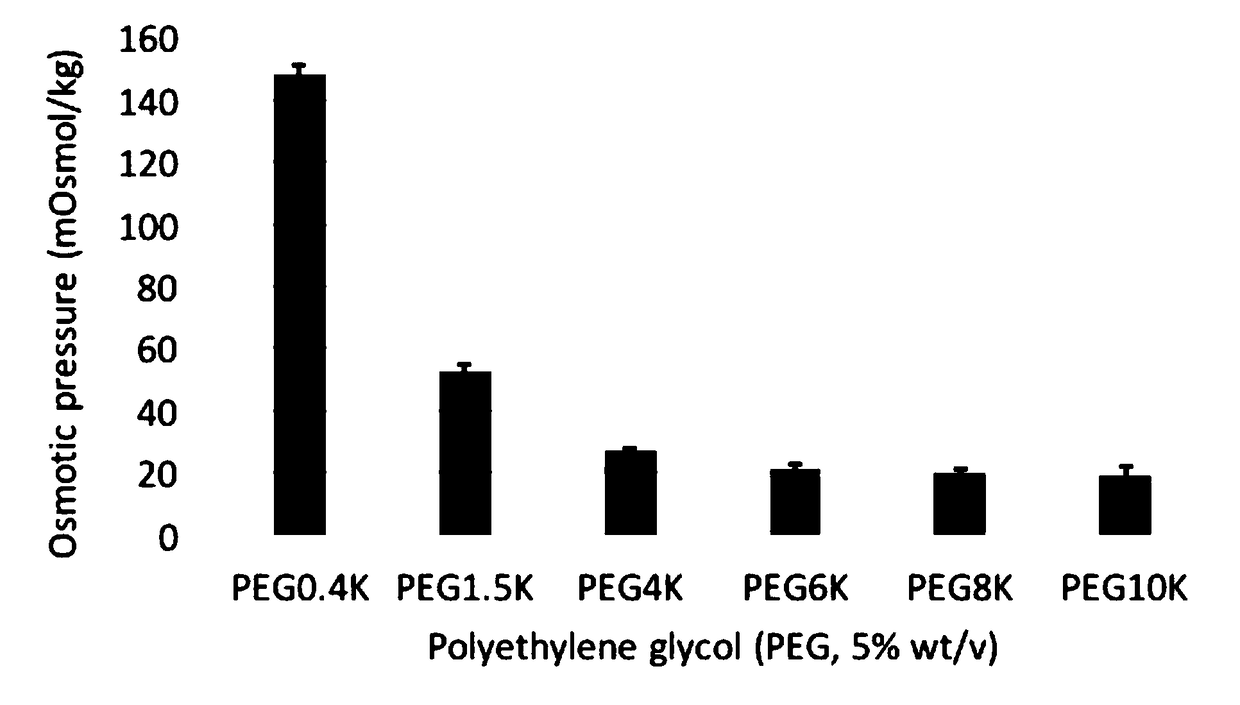

A technology of silk fibroin and hydrogel, which is applied in the fields of medical science, prosthesis, tissue regeneration, etc., can solve the problem of poor biocompatibility, high osmotic pressure of small molecular weight polyethylene glycol, and inability to reflect the biological phase of silk fibroin. Capacitance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides an experimental process and results of the effect of different molecular weight polyethylene glycols on cell proliferation, as follows:

[0041] S1. Refrigerated P2 human bone marrow mesenchymal stem cells were inoculated into T175 cell culture flasks, and cultured in DMEM medium containing 10% FBS and 1% double antibody. When the cells expanded to cover 80% of the bottom of the culture flask, they were washed twice with PBS, digested with 2 mL of 0.25% trypsin, and added 4 mL of cell culture medium to terminate the digestion. Centrifuge, resuspend in cell culture medium, and count.

[0042] S2, 5000 cells / well were seeded in a 24-well cell culture plate, and cultured in DMEM medium containing 10% FBS and 1% double antibody for 12 hours.

[0043] S3. Discard the supernatant, add culture solutions containing different molecular weights and a mass concentration of 5% polyethylene glycol, and continue to cultivate. When culturing for 1 day, 2 days...

Embodiment 2

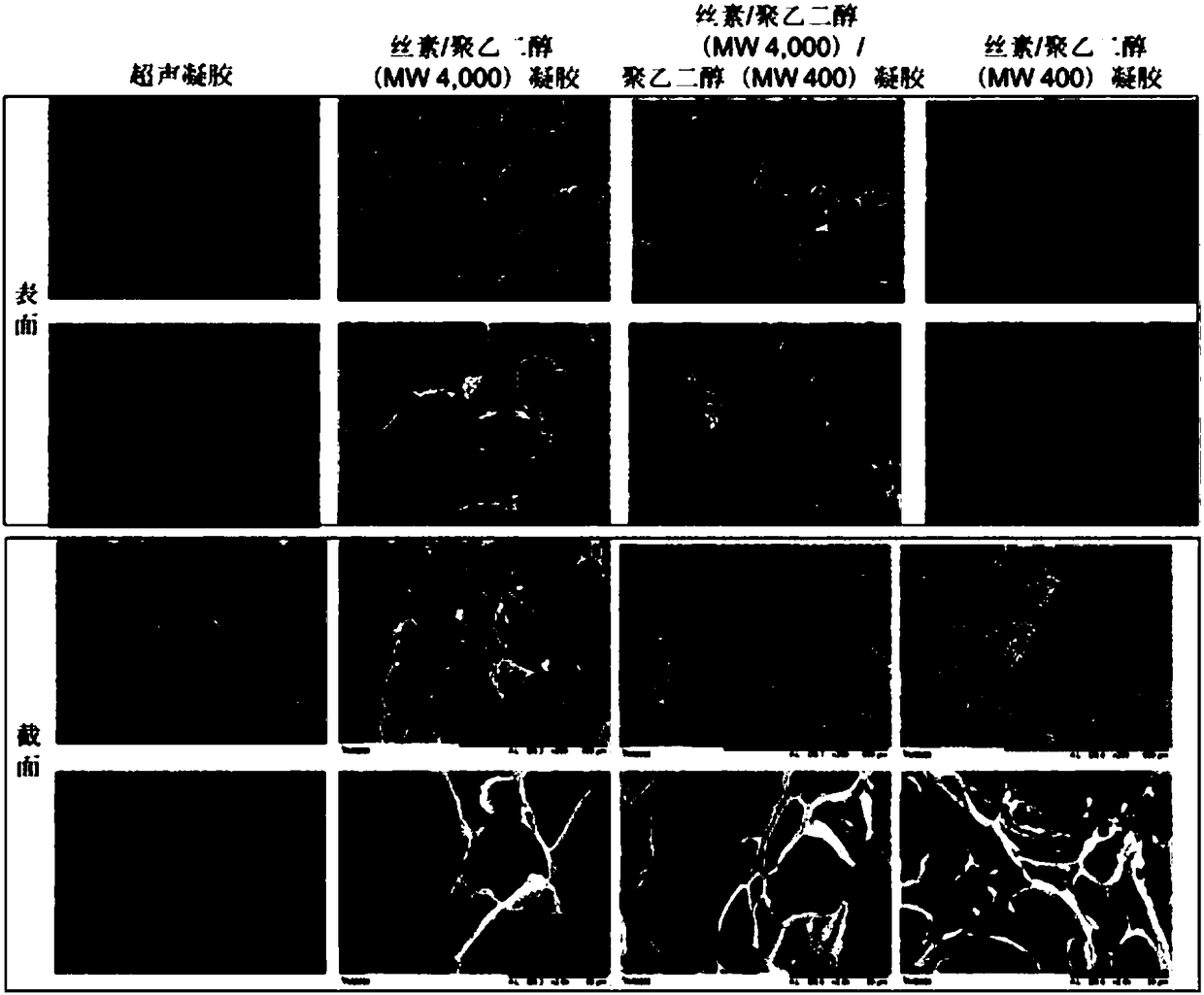

[0055] This example provides a silk fibroin hydrogel prepared by different molecular weight polyethylene glycols and their combinations, and uses scanning electron microscopy to study the three-dimensional structure of the hydrogel to detect the effects of different molecular weight polyethylene glycols on silk fibroin. Influence of protein gel structure. Specific steps are as follows:

[0056] S1. Cut silkworm cocoons into pieces and weigh 100 grams, boil in 40L of 0.02M sodium carbonate aqueous solution for 30 minutes to remove sericin, then repeatedly wash with deionized water for 3 times, put into fume hood after washing Dry and set aside.

[0057] S2. Weigh 10 grams of degummed silk, place it in 40 mL of 9.3 M lithium bromide solution, and treat it at 60° C. for 4 hours. Place in a dialysis device and dialyze against deionized water for 48 hours, and centrifuge to remove insoluble particles.

[0058] S3. Dilute the regenerated silk fibroin solution obtained in S2 to a ...

Embodiment 3

[0071] This example provides a silk fibroin solution that acts on a large molecular weight polyethylene glycol while adding small molecule polyethylene glycol to promote silk fibroin to form a hydrogel. The results of the gelation speed are compared, specifically as follows step:

[0072] S1. Cut silkworm cocoons into pieces and weigh 100 grams, boil in 40L of 0.02M sodium carbonate aqueous solution for 30 minutes to remove sericin, then repeatedly wash with deionized water for 3 times, put into fume hood after washing Dry and set aside.

[0073] S2. Weigh 10 grams of degummed silk, place it in 40 mL of 9.3 M lithium bromide solution, and treat it at 60° C. for 4 hours. Place in a dialysis device and dialyze against deionized water for 48 hours, and centrifuge to remove insoluble particles.

[0074] S3. Adding high molecular weight polyethylene glycol to the silk fibroin solution obtained in step S2, wherein the mass ratio of silk fibroin to polyethylene glycol is 1:1.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com