Bed mud in-situ repair particle, preparation method, usage method and application thereof

An in-situ repair and particle technology, applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve the problems of reduced repair efficiency, slow growth, and damage to covering materials, so as to improve utilization efficiency and prolong release Oxygen time, the effect of simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

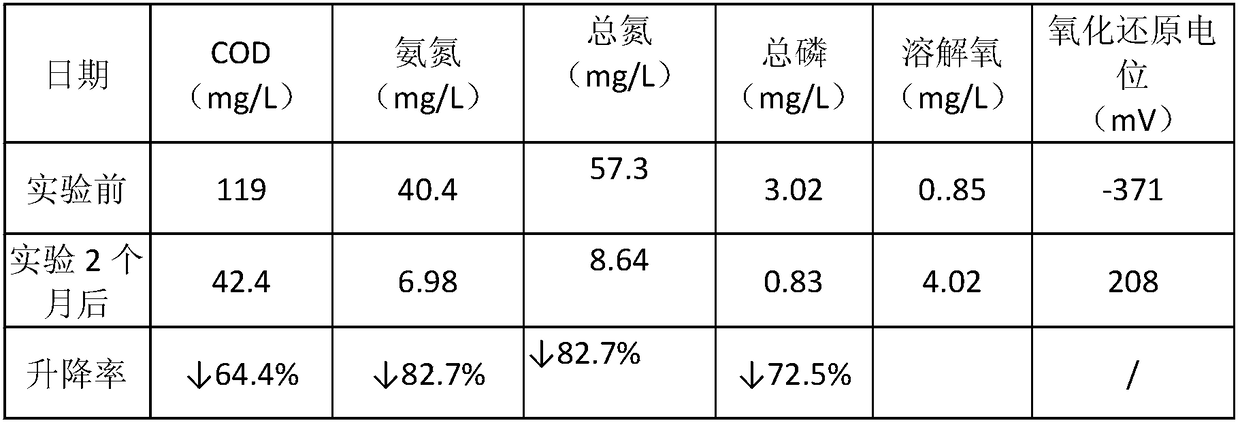

Examples

Embodiment 1

[0036] The present invention is realized through the following technical scheme, a kind of sediment in-situ restoration granules, comprising the following components by weight: 0.02-0.03 parts by weight of polyvinyl alcohol, 2-3 parts by weight of oxygen release agent, and 2-4 parts by weight of zeolite powder 1 to 1.5 parts by weight of ferrous sulfate, and 0.5 to 1.5 parts by weight of bentonite.

[0037] It should be noted that through the above improvements, the use of remediation particles for water remediation can directly act on the polluted part, effectively improve the dissolved oxygen level at the sediment-water interface, the oxidation-reduction potential and the physiological activity of microorganisms in the sediment, and promote the self-purification of the water body. the progress of the process;

[0038]Ferrous sulfate has flocculation performance in the underwater environment, and can play a role in locking phosphorus. At the same time, after the granular mate...

Embodiment 2

[0041] This embodiment is further optimized on the basis of the above embodiments. The oxygen release agent is in powder form, and the mesh size of the oxygen release agent ranges from 100 mesh to 300 mesh.

[0042] The oxygen release agent is calcium peroxide.

[0043] The bentonite is in powder form, and the mesh number of the bentonite is 100 mesh.

[0044] Calcium peroxide is preferably used as the commonly used oxygen release agent due to its environmental friendliness, high oxygen release efficiency, and low price.

[0045] It should be noted that, through the above improvements, after calcium peroxide contacts with water, there are the following two decomposition methods:

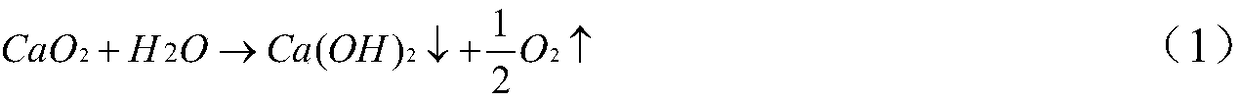

[0046]

[0047] CaO 2 +2H 2 O→Ca(OH) 2 ↓+H 2 o 2 (2)

[0048] The application in environmental remediation is mainly to use equation (1) to use it as calcium peroxide as an oxygen release agent to strengthen aerobic bioremediation.

[0049] Calcium peroxide also has a strong ability to ox...

Embodiment 3

[0057] This embodiment is further optimized on the basis of the above embodiments, a method for preparing sediment in-situ repair particles, which specifically includes the following steps:

[0058] Step S1: preparing a polyvinyl alcohol solution; specifically, the polyvinyl alcohol solution is prepared from polyvinyl alcohol and water, and the mass percent concentration ranges from 1% to 3%.

[0059] Step S2: Weigh and mix the raw materials; specifically, the following steps are included:

[0060] Step S21: weighing raw materials: weighing 2-3 parts by weight of calcium peroxide, 1-1.5 parts by weight of ferrous sulfate, 2-4 parts by weight of zeolite powder, 1-2 parts by weight of polyvinyl alcohol solution, and 0.5-1.5 parts by weight of bentonite share;

[0061] Step S211: dividing the weighed zeolite powder into three equal parts;

[0062] Step S22: Mix calcium peroxide and an equal part of zeolite powder evenly, gradually add 2 / 3 parts by weight of polyvinyl alcohol so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com