A Confined Tube Grouting Pile Suitable for Underground Chloride Erosion Environment

A cast-in-place pile and environmental technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of endangering the bearing capacity and various performances of the pile body, threatening the safety of the superstructure, affecting the quality of the pile body, etc. The effect of good salt erosion performance, reasonable structure combination and stable bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

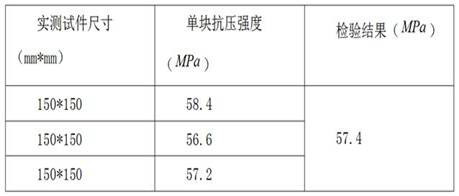

[0032] Production process and implementation effect performance test of constrained pipe grouting piles suitable for underground chloride erosion environment

[0033] 1. Production process of constrained tubular piles for underground chloride erosion environment

[0034] (1) Preparation of fiber-reinforced cement-based composite constrained tube

[0035] 1) The powder material is prepared according to the ratio of fiber content to 5% of the mass percentage of cement. The polymer emulsion accounts for 10% of the powder material, the amount of water reducer accounts for 1% of the powder material, and the water-cement ratio is 0.3. Stir Preparation of fiber-reinforced cement-based composite slurry. The cement is P.O 52.5 Portland cement, the organic fiber is polypropylene fiber, the polymer emulsion is styrene-butadiene latex, and the water reducer is polycarboxylic acid.

[0036] 2) According to the design parameters of outer diameter, wall thickness and pipe length of φ500*22...

Embodiment 2

[0053] Embodiment 2. is basically the same as Example 1, and the difference is that the fiber content accounts for 8% of the cement, the polymer emulsion accounts for 15% of the powder material, the superplasticizer accounts for 2% of the powder material, and the water The gray ratio is 0.40.

[0054] The organic fiber adopts polyacrylonitrile fiber, ultra-high molecular weight polyethylene fiber, polyvinyl alcohol fiber, polyester fiber or polyoxymethylene fiber, and there is no substantial difference in performance. The polymer emulsion adopts styrene-butadiene latex, acrylate emulsion, vinyl acetate emulsion or ethylene-vinyl acetate copolymer emulsion. The water reducing agent adopts polycarboxylic acid, naphthalene series or aliphatic high-efficiency water reducing agent.

Embodiment 3

[0055] Embodiment 3. is basically the same as Example 1, and the difference is that the fiber content accounts for 5% of the cement, the polymer emulsion accounts for 5% of the powder material, the superplasticizer accounts for 1.5% of the powder material, and the water The gray ratio is 0.25.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com