A method for purifying phenolic organic wastewater with cellulose/hectorite hybrid composite material

A composite material and cellulose technology, applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc., to achieve the effect of overcoming easy agglomeration, high removal rate, high removal rate and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) Preparation of hectorite nanomaterials:

[0046]1-A) Dissolve 100mmol of lithium fluoride in 200ml of water, then add 400mmol of magnesium hydroxide, stir at 40-50°C for 2-3h to obtain the first mixed solution;

[0047] 1-B) the first mixed solution is added dropwise in the silica sol (being the SiO of 20%wt 2 water dispersion, SiO in water dispersion 2 The molar weight is 800mmol), stirred at 35-40°C to form a homogeneous mixture, then heated and refluxed for 16-18h to obtain a hectorite dispersion;

[0048] 1-C) Cool the hectorite dispersion to room temperature, centrifuge, collect the filter cake and place it in a toluene solution of 0.5% V oleic acid, ultrasonically disperse it at 80-90°C for 1-2 days, cool down, centrifuge, collect the filter cake The cake is heated to 150-180°C at a heating rate of 5°C / min in an air atmosphere, and finally heat-preserved and dried for 5-6 hours to obtain hectorite nanomaterials (hectorite nanomaterials are abbreviated as Nano...

Embodiment 1-A

[0056] Adopt single factor variable method to replace the cellulose acetate phthalate in embodiment 1 with cellulose acetate, promptly compare with embodiment 1, adopt the cellulose acetate of equal weight to replace cellulose acetate phthalate, all the other with The preparation method of Example 1 is completely consistent. The prepared cellulose / hectorite hybrid composite is defined as C / H.

Embodiment 2

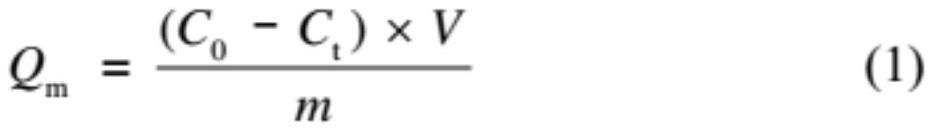

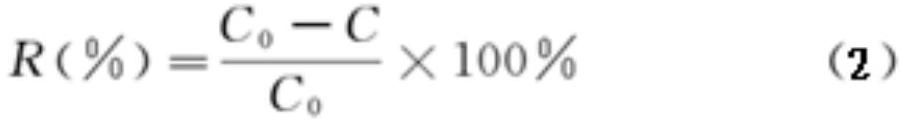

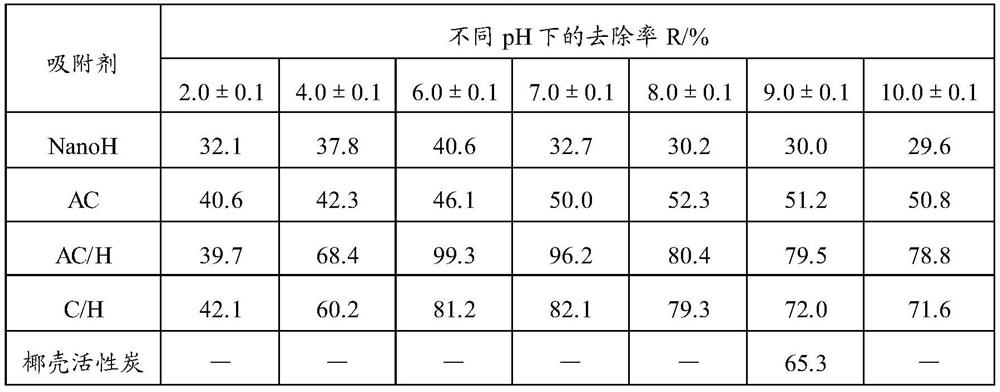

[0058] For the hectorite nanomaterial (NanoH) prepared in Example 1, the cellulose acetate phthalate (AC) grafted with 2-acrylamide-2-methylpropanesulfonic acid, the cellulose / hectorite hybrid compound Material (AC / H) and C / H are the adsorbents to measure the removal rate of phenol at different pH values R (initial concentration of phenol C 0 is 50mg / L, and the addition amount of adsorbent is 40mg / L), and its result is as shown in table 1:

[0059] Table 1 The removal rate R of different adsorbents to phenol at pH

[0060]

[0061] Note: "—" means no test; Front.Environ.Sci.Eng.2013,7(2):158-165,Removal of phenol by powdered activated carbon adsorption reported that coconut shell activated carbon has the maximum adsorption under the condition of pH=9.0 activity, so tests under other pH conditions were not performed.

[0062] The above results show that the cellulose / hectorite hybrid composite material (AC / H) prepared by the present invention has a stronger adsorption an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com