Multi-arm magnetic graphene oxide composite microsphere, preparation method and application thereof

A technology of composite microspheres and oxidized stones, applied in the field of nanomaterials, can solve the problems of low immobilized amount of cellulase and poor activity of immobilized enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

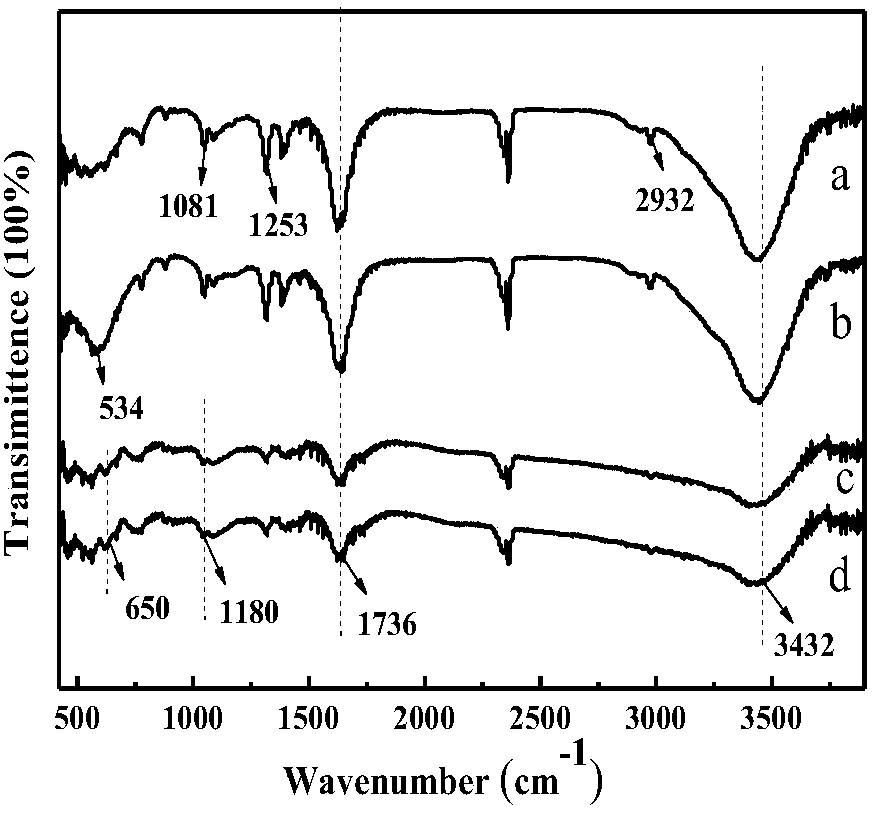

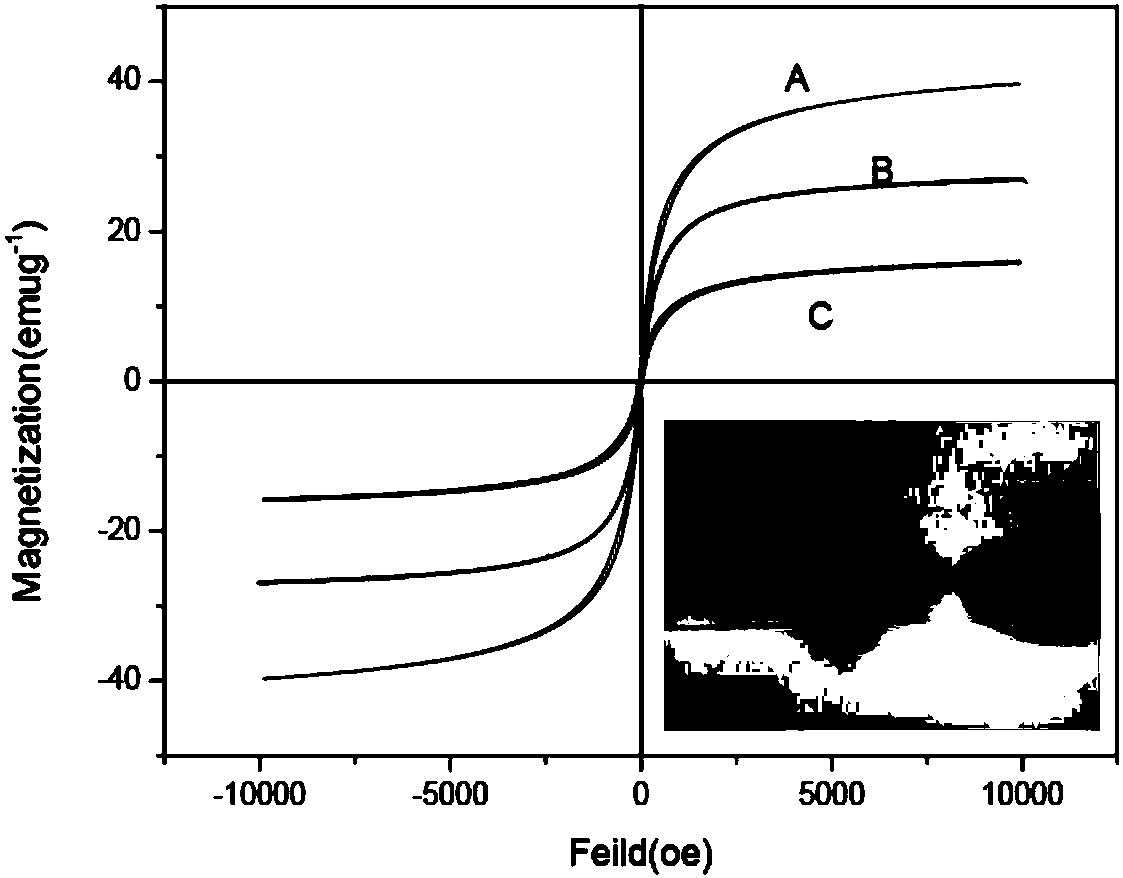

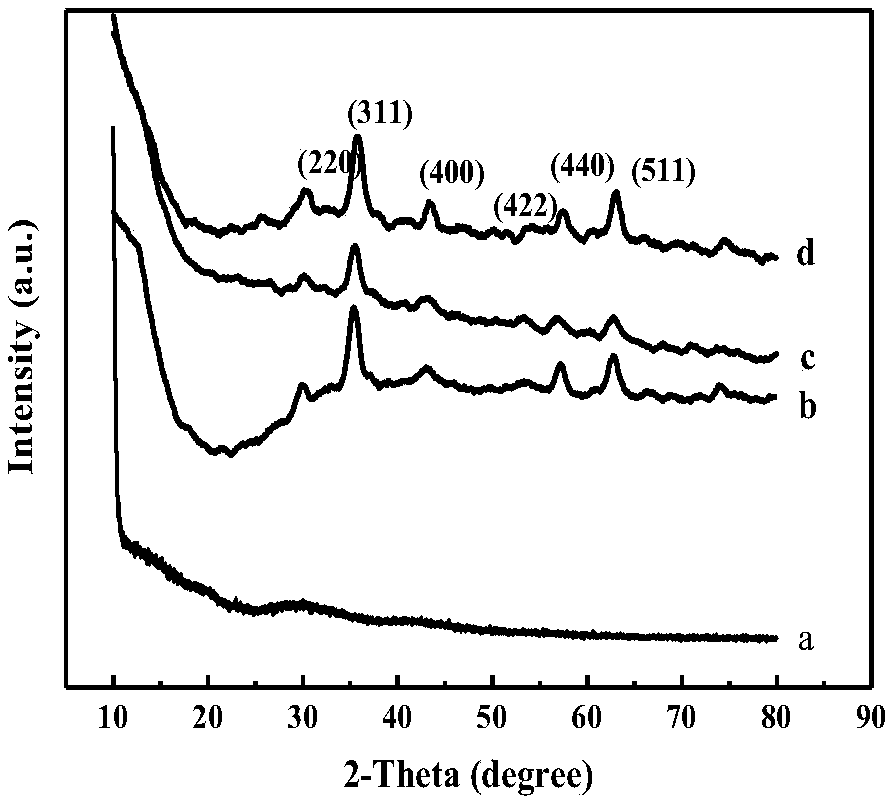

[0064] Example 1: Preparation of multi-arm magnetic graphene oxide composite microspheres and immobilization of enzymes

[0065] (1) Preparation of graphene oxide (GO):

[0066] Accurately weigh 0.1g graphite powder and 0.1g sodium nitrate into a 100 mL beaker, slowly add 17 ml of sulfuric acid solution (12mol / L) to it, and place the beaker in an ice bath and stir for 15 min. Slowly add 2.0 g of potassium permanganate to the above solution, then transfer the suspension to a water bath with a temperature of 20°C, stir it magnetically for 90 minutes, and dilute the resulting brown paste with deionized water and stir for 10 minutes. Finally 4 mL of hydrogen peroxide was added, the reaction solution turned golden yellow, and the reaction was completed. After standing for 24 hours, the supernatant was removed, and the remaining precipitate was separated by suction filtration. The obtained product was washed with 5% hydrochloric acid several times until no white precipitate was detected...

Embodiment 2

[0077] Example 2: Preparation of multi-arm magnetic graphene oxide composite microspheres and immobilization of enzymes

[0078] (1) Preparation of graphene oxide (GO):

[0079] Accurately weigh 0.9 g of graphite powder and 0.9 g of sodium nitrate into a 100 mL beaker, slowly add 29 mL of sulfuric acid solution (12 mol / L) to it, and place the beaker in an ice bath and stir for 15 min. Slowly add 6.0 g of potassium permanganate to the above solution, then transfer the suspension to a water bath with a temperature of 60 ℃, and stir magnetically for 90 min. The resulting brown paste is diluted with deionized water and then stirred for 10 min. Add 8 mL of hydrogen peroxide, the reaction solution turns golden yellow, and the reaction is over. After standing for 24 hours, the supernatant was removed, and the remaining precipitate was separated by suction filtration. The obtained product was washed with 5% hydrochloric acid several times until no white precipitate was detected with bariu...

Embodiment 3

[0090] Example 3: Preparation of multi-arm magnetic graphene oxide composite microspheres and immobilization of enzymes

[0091] (1) Preparation of graphene oxide (GO):

[0092] Accurately weigh 0.5 g of graphite powder and 0.5 g of sodium nitrate into a 100 mL beaker, slowly add 23 mL of sulfuric acid solution (12 mol / L) to it, and place the beaker in an ice bath and stir for 15 min. Accurately weigh 4.0 g of potassium permanganate and slowly add it to the above solution, then transfer the suspension to a 40 ℃ water bath, and magnetically stir for 90 min. The resulting brown paste is diluted with 50 mL of deionized water and then stirred for 10 min. , And finally add 6 mL of hydrogen peroxide, the reaction solution turns golden yellow, the reaction is over. After standing for 24 hours, the supernatant was removed, and the remaining precipitate was separated by suction filtration. The obtained product was washed with 5% hydrochloric acid several times until no white precipitate wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com