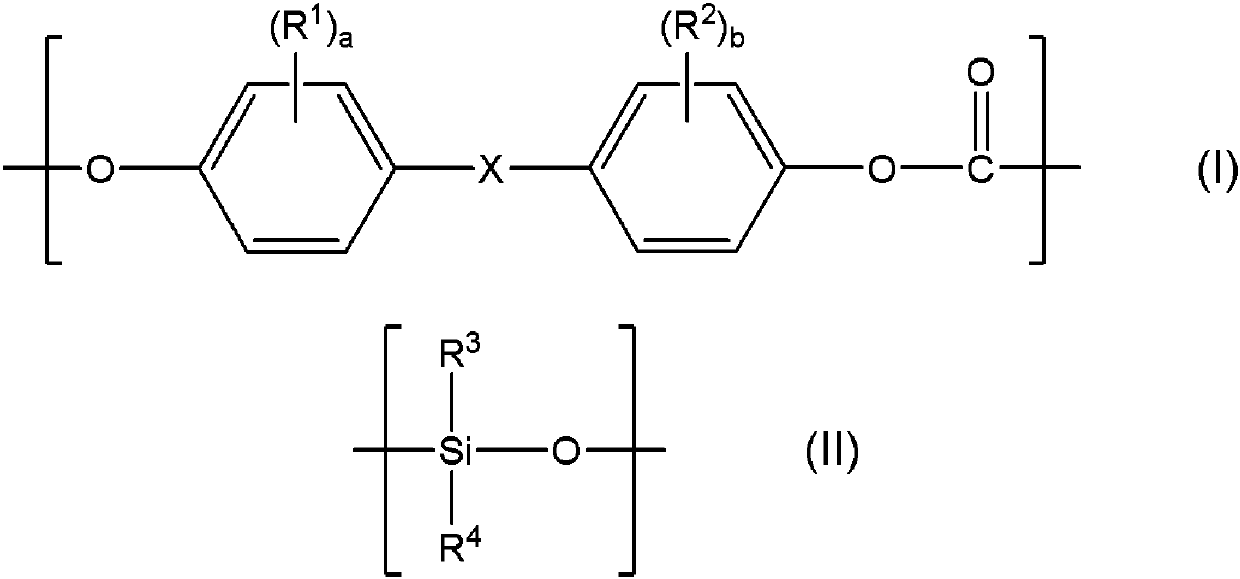

Polycarbonate-based resin composition and molded article thereof

A technology of resin composition and polycarbonate, which is applied in the field of polycarbonate resin composition and its molded products, can solve the problems such as undisclosed suppression, achieve black streak generation suppression, good low-temperature impact resistance, excellent low-temperature resistance shocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0286] Embodiments of the present invention will be further described. It should be noted that the present invention is not limited by these examples. In addition, the measurement and evaluation in each example were performed by the method shown below.

[0287] (Determination of Chloroformate Group Concentration)

[0288] Based on the chloride ion concentration, it was measured by oxidation / reduction titration and silver nitrate titration in reference to JIS-K8203.

[0289] (Measurement of weight average molecular weight (Mw))

[0290]The weight-average molecular weight (Mw) is measured as follows: use tetrahydrofuran as a developing solvent, use GPC column: TOSOH TSK-GEL MULTIPORE HXL-M (2 pieces) + Shodex KF801 (1 piece), temperature 40°C, flow rate 1.0mL / min, detection Device: RI] The standard polystyrene-equivalent molecular weight (weight average molecular weight: Mw) was measured.

[0291] (average chain length and content of polydimethylsiloxane)

[0292] Calculate...

Synthetic example 1

[0345] Synthesis example 1 (synthesis of polycarbonate oligomer)

[0346] 2000 mass ppm of sodium dithionite was added to a 5.6 mass % sodium hydroxide aqueous solution relative to the bisphenol A dissolved thereafter, and bisphenol A was dissolved therein so that the bisphenol A concentration was 13.5 mass %, and bisphenol A was prepared. Aqueous sodium hydroxide solution.

[0347] Under the flow rate of 40 L / hour of sodium hydroxide aqueous solution of bisphenol A and 15 L / hour of dichloromethane, phosgene is continuously passed into a tubular reaction with an inner diameter of 6 mm and a tube length of 30 m at a flow rate of 4.0 kg / hour. device. The tubular reactor has a jacket part, and cooling water is passed through the jacket to keep the temperature of the reaction solution below 40°C.

[0348] The reaction solution coming out of the tubular reactor is continuously introduced into a baffled tank reactor with a swept wing of 40 L internal volume, to which 2.8 L / hour of...

manufacture example 1

[0350] Production example 1 (production of polycarbonate-polydimethylsiloxane copolymer (PC-PDMS1))

[0351] In a 50L tank reactor equipped with a baffle plate, a paddle stirring blade and a cooling jacket, 15L of the polycarbonate oligomer solution produced in Synthesis Example 1, 8.9L of dichloromethane, polydimethylsiloxane 307 g of 2-allylphenol-terminated modified polydimethylsiloxane (PDMS-1) with an average chain length of the alkane block of 90 and 8.8 mL of triethylamine, to which 6.4% by mass of hydrogen was added under stirring 1389 g of aqueous sodium oxide solution was used to react the polycarbonate oligomer and 2-allylphenol end-capped polydimethylsiloxane for 10 minutes.

[0352] Add a dichloromethane solution of p-tert-butylphenol (PTBP) to this polymerization liquid [made by dissolving 129 g of PTBP in 2.0 L of dichloromethane], an aqueous sodium hydroxide solution of bisphenol A [after making 581 g of sodium hydroxide and 2.3 g of sodium disulfite was disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com