Combined SCR (selective catalytic reduction) denitration catalyst with strong anti-poisoning capability and application of catalyst

A technology of denitration catalyst and combined catalyst, which is applied in the field of combined SCR denitration catalyst, can solve the problems of poor water resistance, sulfur resistance, weak alkali resistance and arsenic resistance, narrow operating temperature window, etc. Good industrial application value, high efficiency nitrogen oxide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

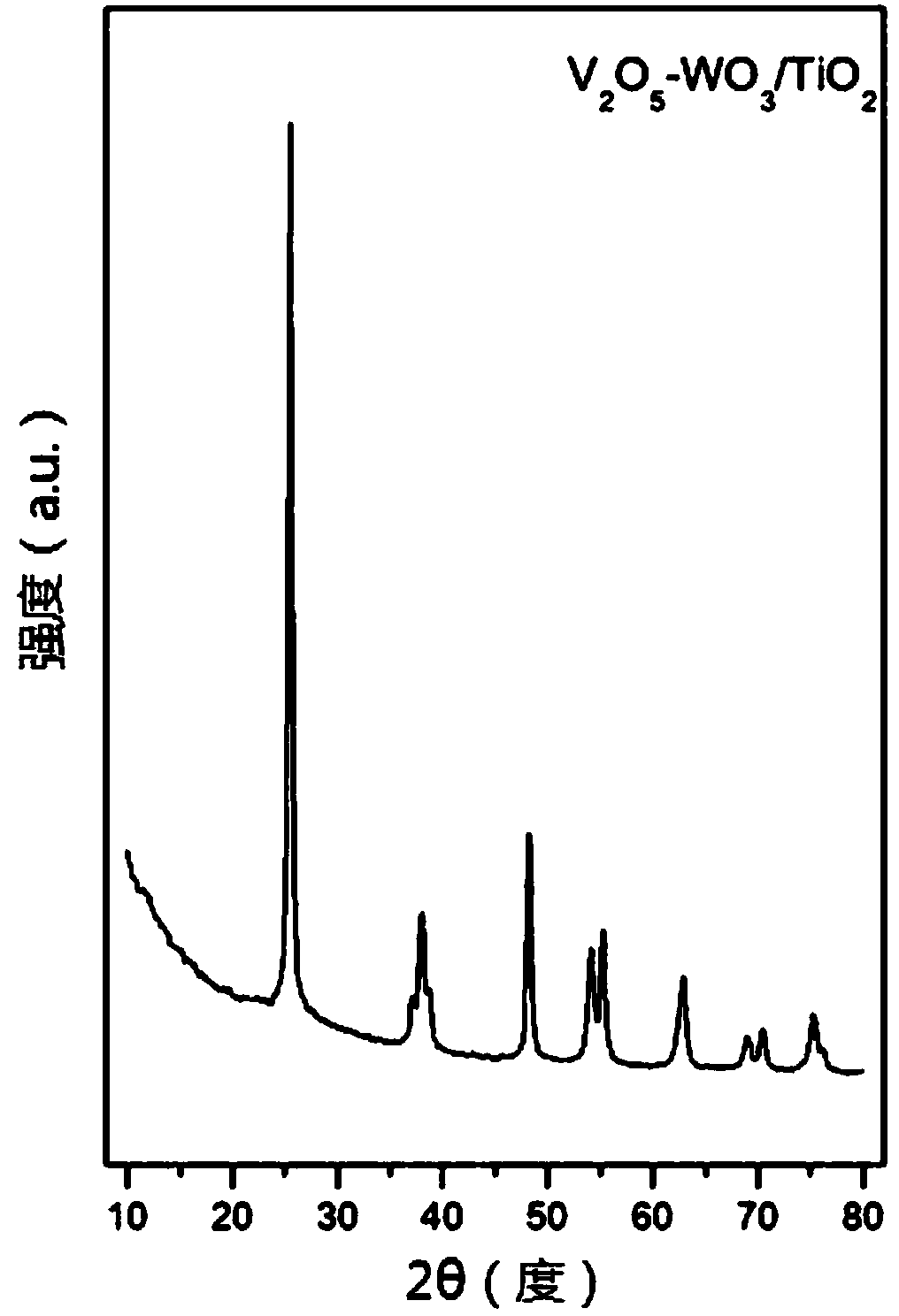

[0046] The catalyst was prepared by a stepwise impregnation method, that is, the TiO 2 surface loading WO 3 Then load V 2 o 5 , making V 2 o 5 -WO 3 / TiO 2 Catalyst, the impregnating solution is ammonium metavanadate and ammonium paratungstate aqueous solution, and a certain amount of oxalic acid is added during the preparation process to help the dissolution. TiO 2 The powder is heated to 60-70°C in ammonium paratungstate solution and stirred for 4 hours, then dried in an oven at 105°C for 12 hours, roasted in a muffle furnace at 500°C for 5 hours, and the roasted product is cooled and crushed and then heated to 60- Stir at 70°C for 4 hours, dry in an oven at 105°C for 12 hours, and bake in a muffle furnace at 500°C for 5 hours. After the product is cooled, crush and sieve it into 40-60 mesh V 2 o 5 -WO 3 / TiO 2 catalyst. The V 2 o 5 -WO 3 / TiO 2 Catalyst, V 2 o 5 The content is 0.5%~2%, WO 3 The content is 3-8%.

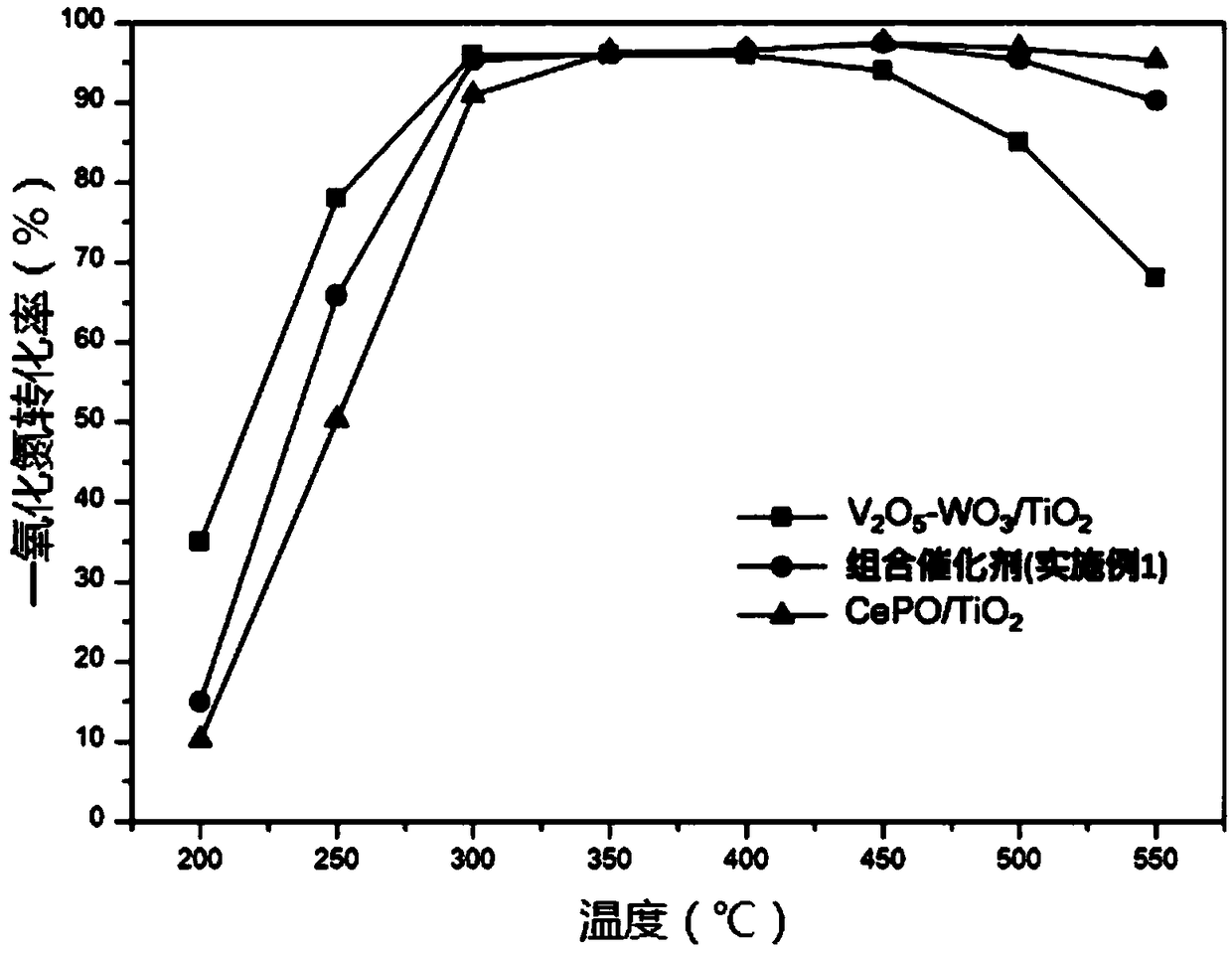

[0047] Combination and activity evaluatio...

Embodiment 1

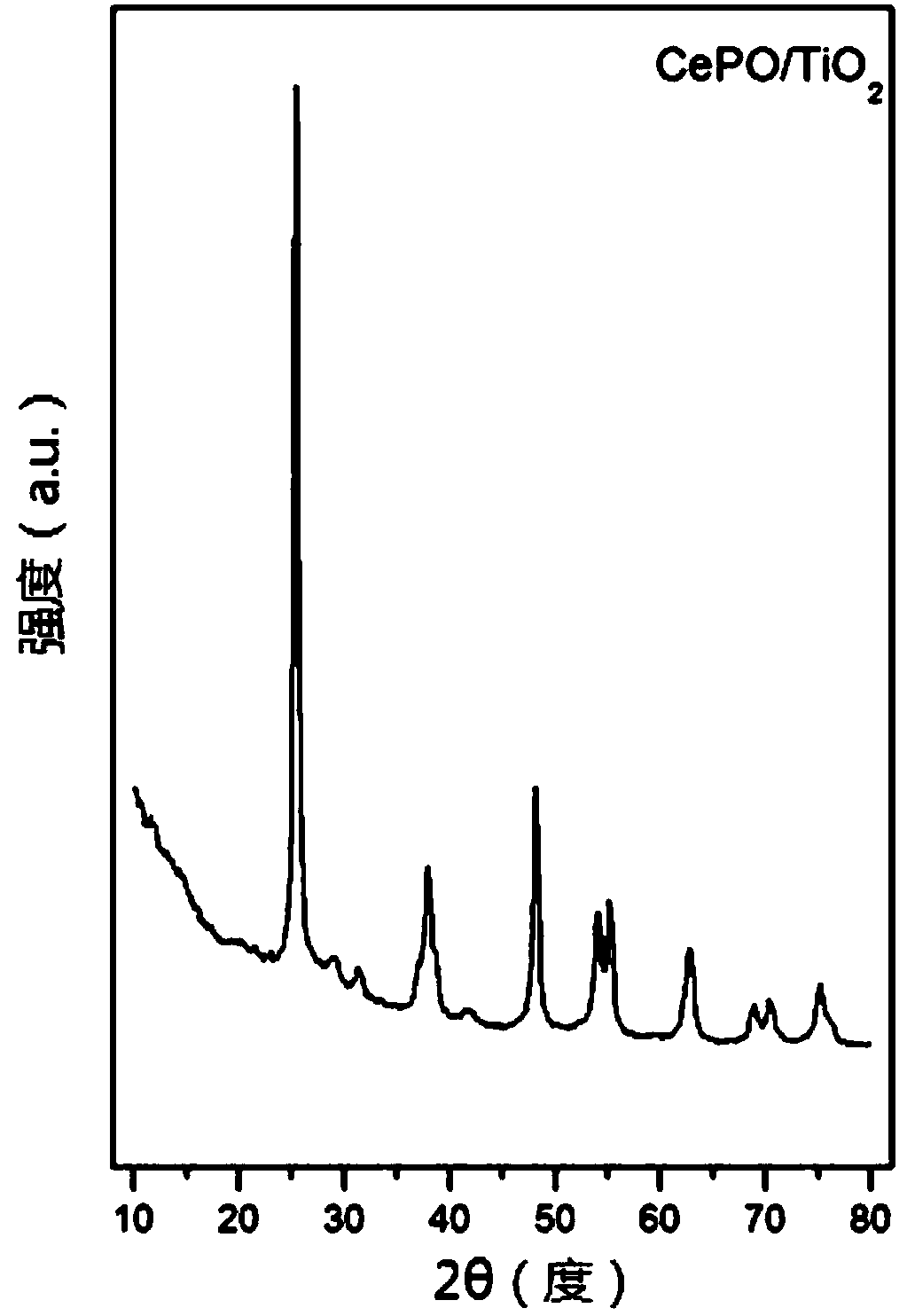

[0055] Weigh 6.20g of cerous nitrate and dissolve it, pour it into 1.40g of phosphoric acid, stir, then add 8.57g of urea to the solution, after the urea is completely dissolved, add 10.0g of TiO 2 Carrier, then began to heat up to 95°C, stirred and evaporated the solution to dryness, then dried in an oven at 110°C for 12 hours, and finally baked at 500°C for 5 hours. After the product was cooled, it was crushed and sieved into CePO / TiO 2 Catalyst, wherein the Ce content is the carrier TiO 2 20% of the mass, Ce:P (molar ratio) is 1:1.

[0056] Weigh 1.0g of oxalic acid and add it into the aqueous solution containing 0.55g of ammonium paratungstate, stir to dissolve, and mix 10.0g of TiO 2 The powder is heated to 60-70°C in the ammonium paratungstate solution and stirred for 4 hours, then dried in an oven at 105°C for 12 hours, roasted in a muffle furnace at 500°C for 5 hours, and the roasted product is cooled and crushed in an aqueous solution containing 0.13g of ammonium m...

Embodiment 2

[0059] The staged catalyst preparation method is the same as in Example 1.

[0060] The prepared two catalysts are divided into upper and lower catalyst beds and loaded in the constant temperature section of the reactor. The two-layer catalyst loading method is CePO / TiO 2 On top (air intake), V 2 o 5 -WO 3 / TiO 2 Under (gas outlet), CePO / TiO 2 and V 2 o 5 -WO 3 / TiO 2 The mass ratio is 1:2. Catalyst activity evaluation means is the same as embodiment 1, NO x The conversion rate is detailed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com