A kind of preparation method of porous nano stannous oxide

A technology of stannous oxide and stannous chloride, applied in the directions of tin oxide, nanotechnology, nanotechnology, etc., can solve the problems of poor uniformity and porous performance, achieve uniformity improvement, prevent agglomeration, and improve uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

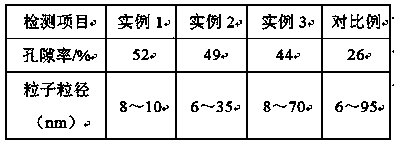

Examples

example 1

[0025]Mix soybean protein isolate and sodium hydroxide solution with a mass fraction of 5% in a beaker at a mass ratio of 1:3, and add distilled water 10 times the amount of soybean protein isolate to the beaker, at a temperature of 88°C and a rotation speed of 400r / Under the condition of stirring and mixing for 50 minutes, the soybean protein gel was obtained. The soybean protein gel was mixed with the organic aldehyde solution at a mass ratio of 9:1. After standing and aging at room temperature for 26 hours, the soybean protein gel was obtained. The soybean protein gel was pulverized, frozen in liquid nitrogen for 6 minutes, and then vacuum-dried to obtain a protein porous material; the protein porous material and trioctylamine were mixed in a flask at a mass ratio of 1:8, and the protein porous material was added to the flask Oxalic acid with 3 times the mass was stirred and mixed for 40 minutes at a temperature of 55°C and a rotational speed of 400r / min, and then filtered ...

example 2

[0027] Mix soybean protein isolate and sodium hydroxide solution with a mass fraction of 5% in a beaker at a mass ratio of 1:3, and add distilled water 10 times the amount of soybean protein isolate to the beaker, at a temperature of 88°C and a rotation speed of 400r / Under the condition of stirring and mixing for 50 minutes, the soybean protein gel was obtained. The soybean protein gel was mixed with the organic aldehyde solution at a mass ratio of 9:1. After standing and aging at room temperature for 26 hours, the soybean protein gel was obtained. The soybean protein gel was pulverized, frozen in liquid nitrogen for 6 minutes, and then vacuum-dried to obtain a protein porous material; the protein porous material and trioctylamine were mixed in a flask at a mass ratio of 1:8, and the protein porous material was added to the flask Oxalic acid with 3 times the mass was stirred and mixed for 40 minutes at a temperature of 55°C and a rotational speed of 400r / min, and then filtered...

example 3

[0029] Mix soybean protein isolate and sodium hydroxide solution with a mass fraction of 5% in a beaker at a mass ratio of 1:3, and add distilled water 10 times the amount of soybean protein isolate to the beaker, at a temperature of 88°C and a rotation speed of 400r / Under the condition of stirring and mixing for 50 minutes, the soybean protein gel was obtained. The soybean protein gel was mixed with the organic aldehyde solution at a mass ratio of 9:1. After standing and aging at room temperature for 26 hours, the soybean protein gel was obtained. The soybean protein gel was pulverized, frozen in liquid nitrogen for 6 minutes, and then vacuum-dried to obtain a protein porous material; the protein porous material and trioctylamine were mixed in a flask at a mass ratio of 1:8, and the protein porous material was added to the flask Oxalic acid with 3 times the mass was stirred and mixed for 40 minutes at a temperature of 55°C and a rotational speed of 400r / min, and then filtered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com