Ultrafine zirconia nanosphere and preparation method thereof

A technology of ultra-fine zirconia and nanospheres, applied in zirconia, nanotechnology, etc., can solve the problems of low output rate, complex synthesis reaction, long reaction time, etc., and achieve good crystallinity, high specific surface area, and chemical properties lively effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

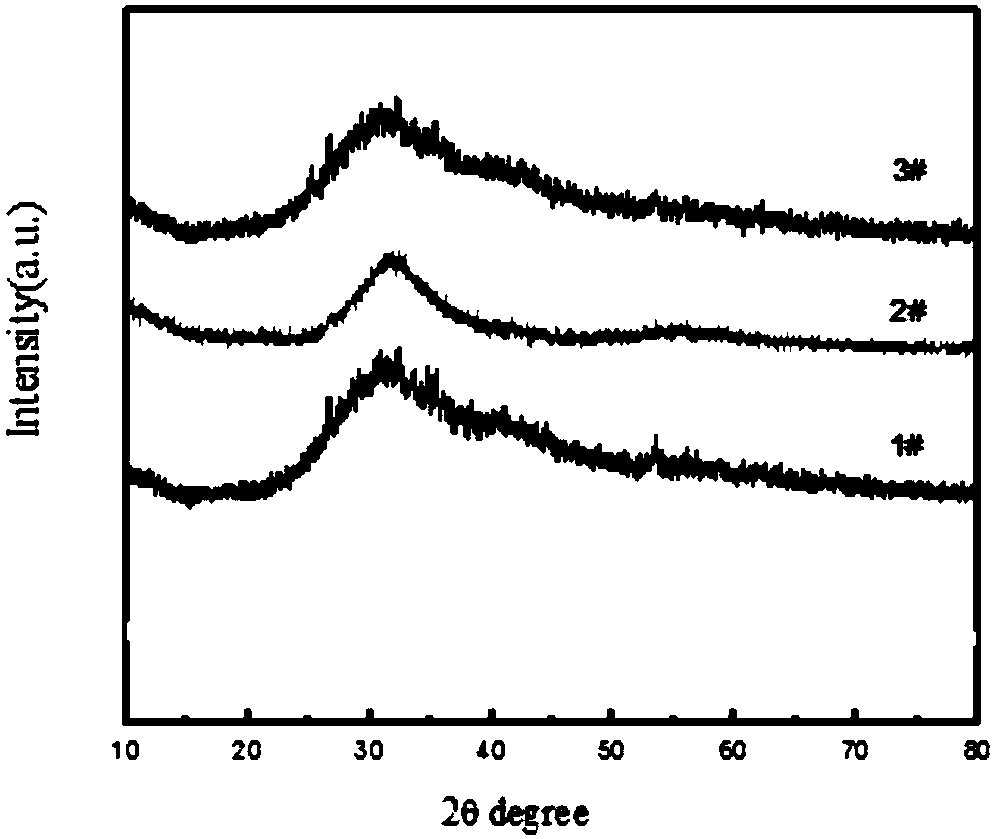

[0029] (1) Mix pure cerium, pure aluminum, pure copper, and pure zirconium according to the atomic ratio of 65:10:20:5, use argon (pressure 0.5MPa) atmosphere protection, and arc smelt 3 times until the composition of the mother ingot is uniform Finally, a cerium-aluminum-copper-zirconium alloy master ingot is obtained; the above-mentioned alloy master ingot is processed by a single-roller spin quenching system, and the rotational speed of the copper roller is set in the range of 1200-1700r / min to obtain a thickness between 35μm-60μm and a width of The thin strip between 2.7-4.0mm, its X-ray diffraction analysis pattern is as follows figure 1 As shown in 1# in the middle: 1# presents a broad diffraction "steamed bread peak", which is a typical amorphous diffuse peak, indicating that the obtained thin band is an amorphous thin band;

[0030] (2) Weigh 0.25 g of the thin strip obtained in step (1), cut it into small pieces, place it in 100 mL of nitric acid solution with a conce...

Embodiment 2

[0033] (1) Mix pure cerium, pure copper, zirconium-aluminum alloy (the mass percentage of aluminum is 20.5%) according to the atomic ratio of cerium, aluminum, copper and zirconium 55:13:17:15, and use argon gas (pressure 0.5 MPa) atmosphere protection, arc melting 4 times, after the composition of the mother ingot is uniform, the cerium-aluminum-copper-zirconium alloy master ingot is obtained; the above alloy master ingot is processed by a single-roller rotary quenching system, and the copper roller speed is set at 1500-2000r In the range of / min, a thin strip with a thickness between 25μm-55μm and a width between 2.5-3.7mm is obtained, and its X-ray diffraction analysis pattern is as follows figure 1 As shown in 2#: 2# presents a broad diffraction "steamed bread peak", which is a typical amorphous diffuse peak, indicating that the obtained thin band is an amorphous thin band;

[0034] (2) Weigh 0.25 g of the thin strip obtained in step (1), cut it into small pieces, place it...

Embodiment 3

[0037](1) Cerium, copper-aluminum alloy (where the mass percentage of aluminum is 9.0%), zirconium-aluminum alloy (wherein the mass percentage of aluminum is 10.0%) is cerium, aluminum, copper, zirconium atomic ratio 40:15:15:30 Proportional mixing, using argon (pressure 0.5MPa) atmosphere protection, arc melting 5 times, after the composition of the mother ingot is uniform, the cerium-aluminum-copper-zirconium alloy mother ingot is obtained; the above alloy mother ingot is processed by a single-roller spin quenching system , the speed of the copper roller is set in the range of 2000-2500r / min, and a thin strip with a thickness of 25μm-60μm and a width of 2.7-3.9mm is obtained, and its X-ray diffraction analysis pattern is as follows figure 1 As shown in 3#: 3# presents a broad diffraction "steamed bread peak", which is a typical amorphous diffuse peak, indicating that the obtained thin band is an amorphous thin band;

[0038] (2) Weigh 0.25 g of the thin strip obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com