Anti-sulfur poisoning platinum catalyst and preparation method thereof

A platinum catalyst, platinum catalyst technology, applied in the field of anti-sulfur poisoning platinum catalyst and its preparation, can solve the problems of platinum catalyst poisoning, loss of catalytic activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

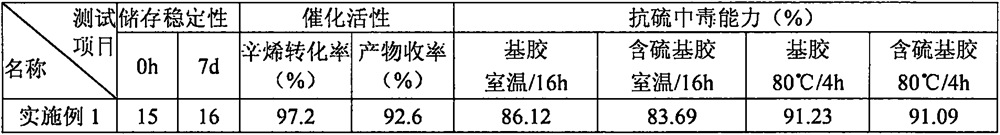

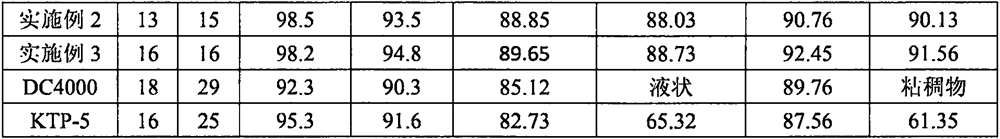

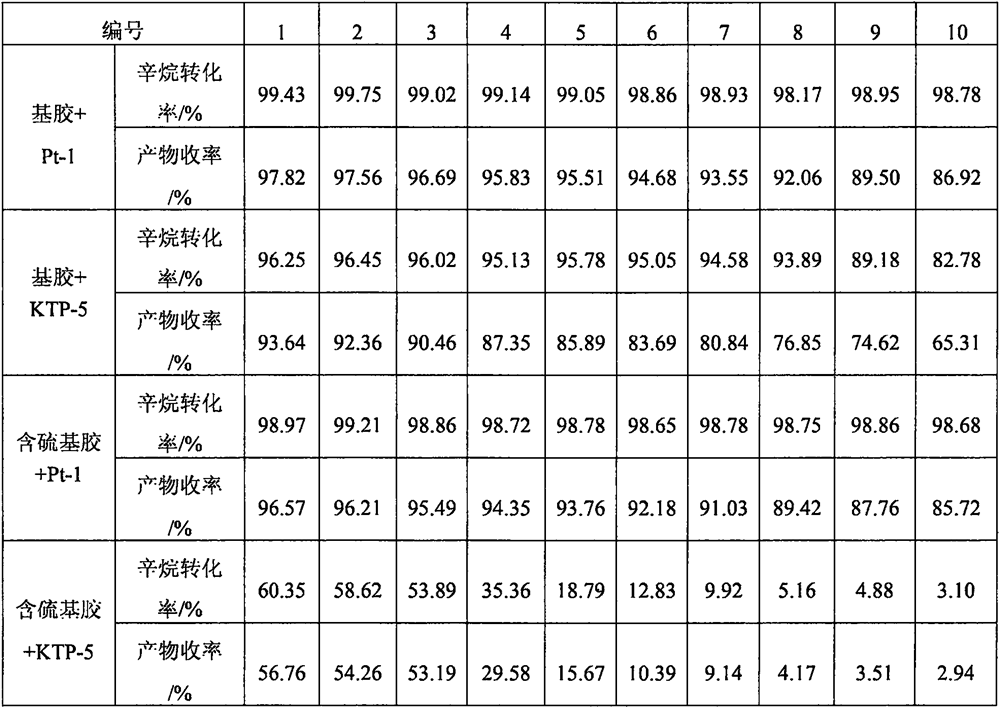

Examples

Embodiment 1

[0051] The preparation method of anti-poisoning platinum catalyst (Pt-1) comprises the following steps:

[0052] A, get nano-graphite (1.00g, average particle diameter 30nm, manufacturer is Kramer's reagent) ultrasonic dispersion in 75g toluene and 25g ethanol, then add 3.00g 3-aminopropyltriethoxysilane (APTS) ( 0.0135mol), stirred for 10min, slowly heated to 90°C, added 1.00g trifluoromethanesulfonic acid and 0.36g water (0.02mol), stirred and reacted at 90°C for 48h, then washed with 100g water, 75g toluene and 25g ethanol in sequence, pumped After filtration, vacuum-dry at 100°C for 24 hours, and grind to obtain modified nano-graphite;

[0053] B. Add 75.08g benzene, 37.54g ethanol, 30.45g 2,5-dihydroxy-1,4-dithiane to a four-neck flask with condenser, nitrogen inlet and constant pressure funnel (0.2mol) and 44.63g cis-dichlorobis(diethylsulfide) platinum (II) (0.1mol), stirred for 20min, added 0.75g dichloroacetic acid (0.0058mol) and 0.75g concentrated sulfuric acid (m...

Embodiment 2

[0056] The preparation method of anti-poisoning platinum catalyst (Pt-2) comprises the following steps:

[0057] A, get 3.00g nano white carbon black (average particle diameter is 12nm, manufacturer is Cabot) ultrasonic dispersion in the mixed solvent of 80g xylene and 20g isopropanol, then add 5.00g N-aminoethyl-3 - Aminopropylmethyldimethoxysilane (0.024mol) was stirred for 20min, slowly heated to 100°C, 2g of trifluoromethanesulfonic acid and 0.52g of distilled water (0.03mol) were added, stirred at 100°C for 36h, and then 100g of Wash with water, 80g xylene and 20g isopropanol, suction filter, then vacuum dry at 100°C for 20h, and grind to obtain modified nano activated carbon;

[0058] B. Add 168.59g of petroleum ether, 59.01g of isopropanol, and 40.65g of 4-(1,3-dithiolane)phenol into a four-neck flask with a condenser, nitrogen inlet and constant pressure funnel (0.205mol) and 44.63g trans-dichlorobis(diethylsulfide) platinum (II) (0.1mol), stirred for 30min, added 1....

Embodiment 3

[0061] The preparation method of anti-poisoning platinum catalyst (Pt-3) comprises the following steps:

[0062] A. Take 5.00g nanometer SiC (the average particle size is 50nm, the manufacturer is Shanghai Yaotian New Material Co., Ltd.) and ultrasonically disperse it in a mixed solvent of 82.00g cyclohexane and 18.00g tetrahydrofuran, and then add 8.00g p-aminophenyl Trimethoxysilane (0.0375mol), stirred for 30min, slowly heated to 110°C, added 2.00g of strongly acidic cationic resin and 1.62g of distilled water (0.09mol), stirred and reacted at 110°C for 24h, then successively added 100g of water, 82.00g of cyclohexane alkane and 18.00g tetrahydrofuran, and then vacuum-dried at 100°C for 12 hours, and ground to obtain modified nano-SiC;

[0063] B. Add 215.65g cyclohexane, 71.88g acetone, 28.61g 1,3-dithiapentane-2-ylmethanol in a four-neck flask with a condenser, nitrogen inlet and constant pressure funnel (0.21mol) and 44.63g cis-dichlorobis(diethylsulfide) platinum (II)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com