Low-foam type glufosinate ammonium auxiliary agent and preparation technology thereof

A technology of glufosinate adjuvant and fatty acyldiethanolamine phosphate, which is applied in the direction of herbicides, algicides, biocides, biocides, etc., can solve the problems of long drug effect time, achieve significant adhesion performance, increase Good adhesion time and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

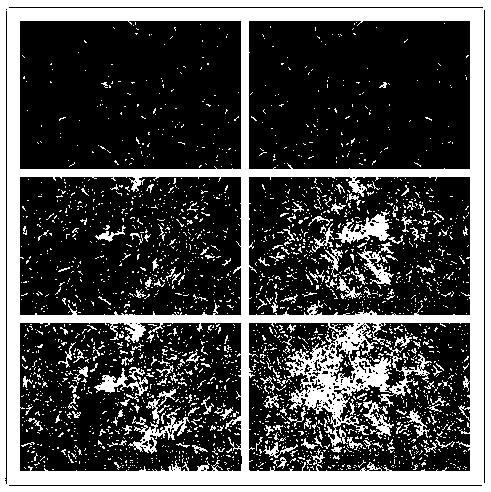

Image

Examples

preparation example Construction

[0018] A kind of preparation technology of low-foaming type glufosinate adjuvant mainly comprises the following steps:

[0019] Step 1. Add deionized water into the reactor, start stirring, add weighed fatty alcohol polyoxyethylene ether and coconut oil fatty acyldiethanolamine phosphate, stir and heat to 60°C to obtain material a;

[0020] Step 2, adding methyl stearate polyoxyethylene ether, heating and stirring to obtain material b;

[0021] Step 3: Add disodium cocoyl monoethanolamide sulfosuccinate monosodium DMSS and PEG (polyethylene glycol), make up deionized water, and stir evenly to obtain a low-foaming glufosinate additive.

[0022] The present invention has implementation:

Embodiment 1

[0024] Take the following weight materials: the first step, add deionized water to the reaction kettle, start stirring, add 8% fatty alcohol polyoxyethylene ether and 10% coconut oil fatty acyldiethanolamine phosphate, stir and heat to 60°C; in the second step, add 25% of methyl stearate polyoxyethylene ether, heat and stir uniformly; in the third step, add 5% of cocoic acid monoethanolamide sulfosuccinic acid monosodium disodium DMSS, After adding 1% polyethylene glycol, make up deionized water and stir evenly.

[0025] pH measurement method:

[0026] Weigh 1.0 g of the product of Example 1 and put it into a beaker, add deionized water to 100 g, stir evenly, and measure the pH value with a pH meter.

[0027] Viscosity determination method:

[0028] Equipment: rotational viscometer; the liquid to be measured is placed in a beaker or a straight container with a diameter of not less than 70 mm, the temperature of the liquid to be measured is accurately controlled, and the prot...

Embodiment 2

[0033]Take the following weight materials: the first step, add deionized water to the reaction kettle, start stirring, add 10% fatty alcohol polyoxyethylene ether and 12% coconut oil fatty acyldiethanolamine phosphate, stir and heat to 60°C; in the second step, add 30% methyl stearate polyoxyethylene ether, heat and stir evenly; in the third step, add 8% cocoic acid monoethanolamide sulfosuccinic acid monosodium disodium DMSS, After adding 1% polyethylene glycol, add deionized water and stir evenly.

[0034] The pH value of the low-foaming glufosinate adjuvant prepared by this formula was measured to be 5.6, the viscosity to be 375mPa.s, and the surface tension to be 16.1mN / m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com