Production process of urea formaldehyde synergistic compound fertilizer

A production process and urea-formaldehyde technology, applied in the field of compound fertilizers, can solve the problems of inability to achieve controlled nutrient release, P and K leaching loss, and low granulation rate, and achieve increased microbial mineral decomposition and polysaccharide secretion, slowing The effect of enhancing the release effect and promoting the growth of crops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

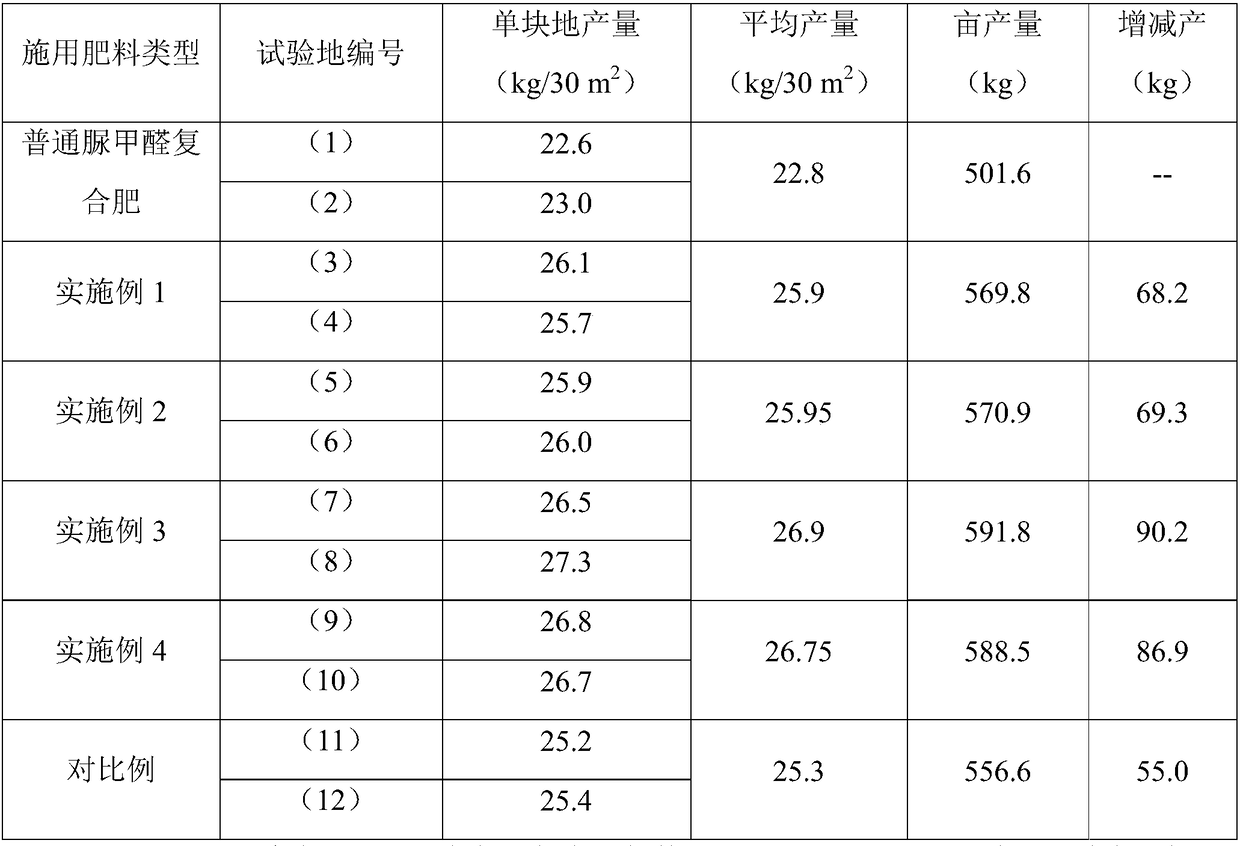

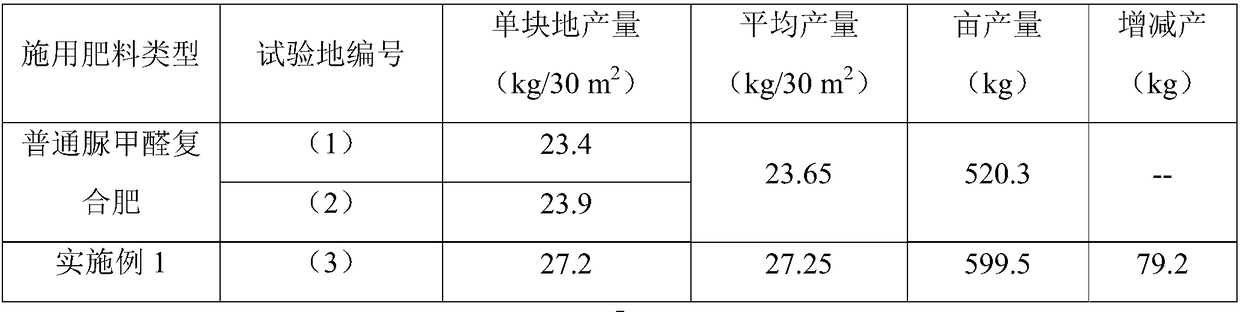

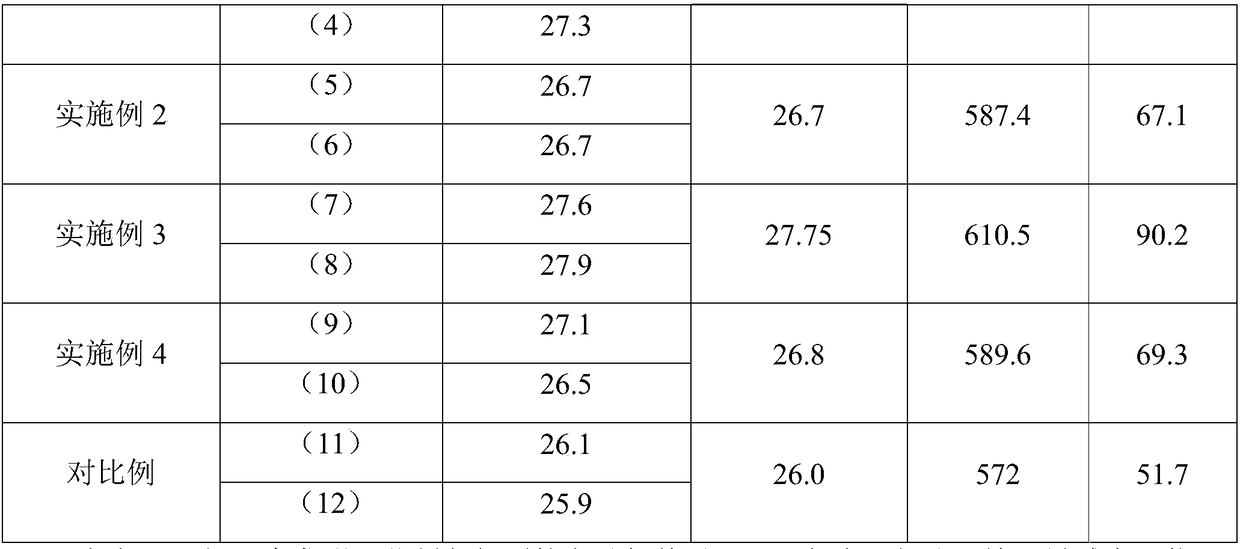

Examples

Embodiment 1

[0028] A kind of urea-formaldehyde synergistic compound fertilizer production process, comprises the following steps:

[0029] 1. Add urea to formaldehyde solution, the molar ratio of urea to formaldehyde is 1.3:1, heat to dissolve, add sodium hydroxide to adjust the pH value to 7.0-7.5, keep the temperature at 40-60°C, add reaction for 1 hour, and obtain methylol urea solution;

[0030] 2. Add industrial sulfuric acid or phosphoric acid to the hydroxymethyl urea solution, adjust the pH value to 4.0-4.5, stir, and condense for 1 hour to obtain a urea-formaldehyde solution for later use;

[0031] 3. Weigh urea, diammonium phosphate, and potassium chloride, add water to dissolve, stir evenly, add bentonite and stir to form an emulsion, then add sodium carboxymethyl cellulose, continue stirring until completely dissolved, add a cross-linking agent to react, and obtain a composite water Gel microspheres are washed with water and dried to constant weight to obtain gel materials, w...

Embodiment 2

[0038] A kind of urea-formaldehyde synergistic compound fertilizer production process, comprises the following steps:

[0039] 1. Add urea to formaldehyde solution, the molar ratio of urea to formaldehyde is 1.3-1.6:1, heat to dissolve, add sodium hydroxide to adjust the pH value to 7.0-7.5, keep the temperature at 40-60°C, add reaction for 1 hour, and obtain methylol urea solution;

[0040] 2. Add industrial sulfuric acid or phosphoric acid to the hydroxymethyl urea solution, adjust the pH value to 4.0-4.5, stir, and condense for 1 hour to obtain a urea-formaldehyde solution for later use;

[0041] 3. Weigh urea, diammonium phosphate, and potassium chloride, add water to dissolve, stir evenly, add bentonite and stir to form an emulsion, then add sodium carboxymethyl cellulose, continue stirring until completely dissolved, add a cross-linking agent to react, and obtain a composite water Gel microspheres are washed with water and dried to constant weight to obtain gel material...

Embodiment 3

[0048] A kind of urea-formaldehyde synergistic compound fertilizer production process, comprises the following steps:

[0049] 1. Add urea to formaldehyde solution, the molar ratio of urea to formaldehyde is 1.3-1.6:1, heat to dissolve, add sodium hydroxide to adjust the pH value to 7.0-7.5, keep the temperature at 40-60°C, add reaction for 1 hour, and obtain methylol urea solution;

[0050] 2. Add industrial sulfuric acid or phosphoric acid to the hydroxymethyl urea solution, adjust the pH value to 4.0-4.5, stir, and condense for 1 hour to obtain a urea-formaldehyde solution for later use;

[0051] 3. Weigh urea, diammonium phosphate, and potassium chloride, add water to dissolve, stir evenly, add bentonite and stir to form an emulsion, then add sodium carboxymethyl cellulose, continue stirring until completely dissolved, add a cross-linking agent to react, and obtain a composite water Gel microspheres are washed with water and dried to constant weight to obtain gel material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com