Soil conditioner production process and equipment applying same

A soil conditioner and production equipment technology, applied in soil conditioning materials, chemical/physical processes, applications, etc., can solve problems such as poor quality consistency, large particle size changes, complex production processes, etc., to ensure quality consistency. , Improve the use efficiency and reduce the effect of the activity space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

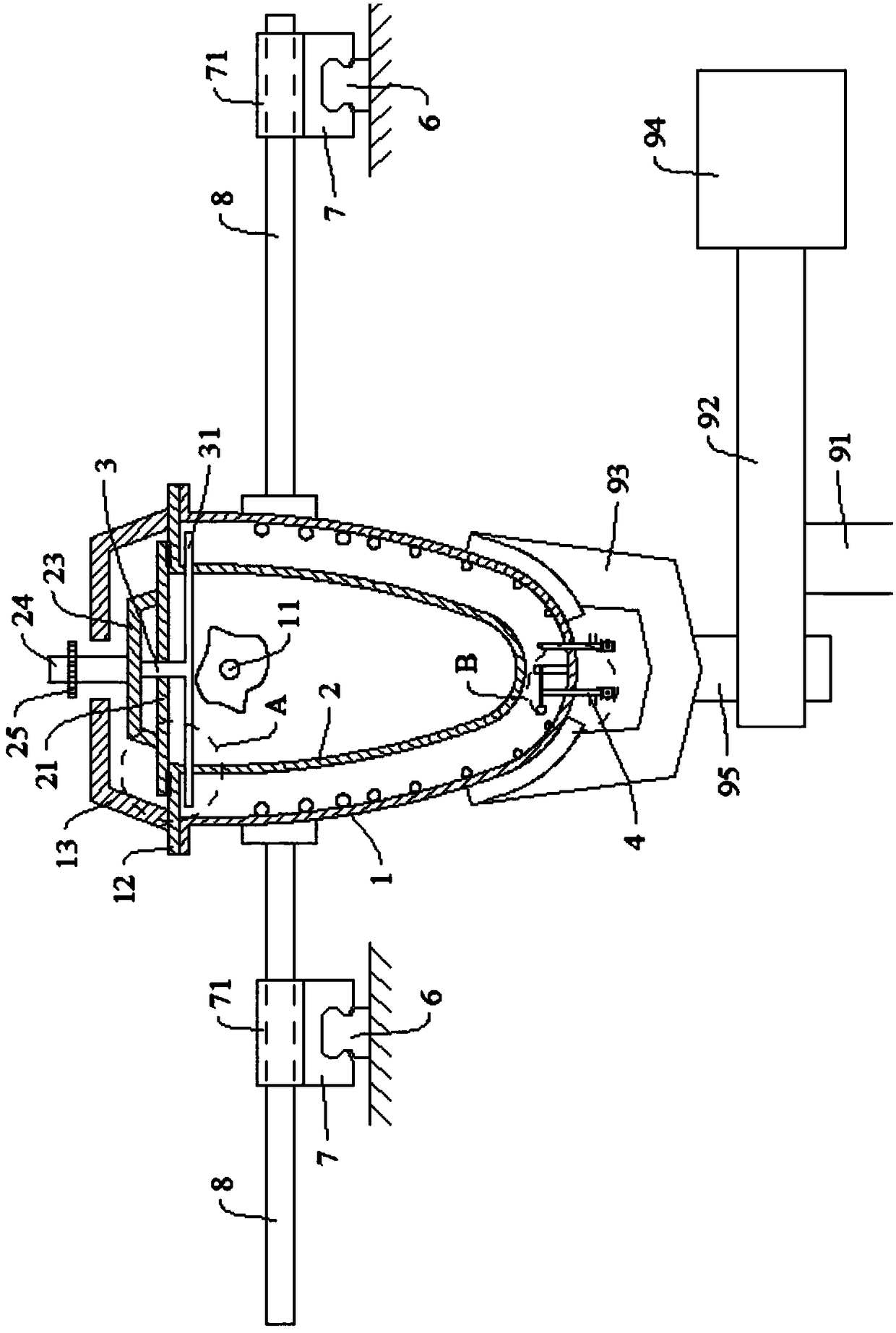

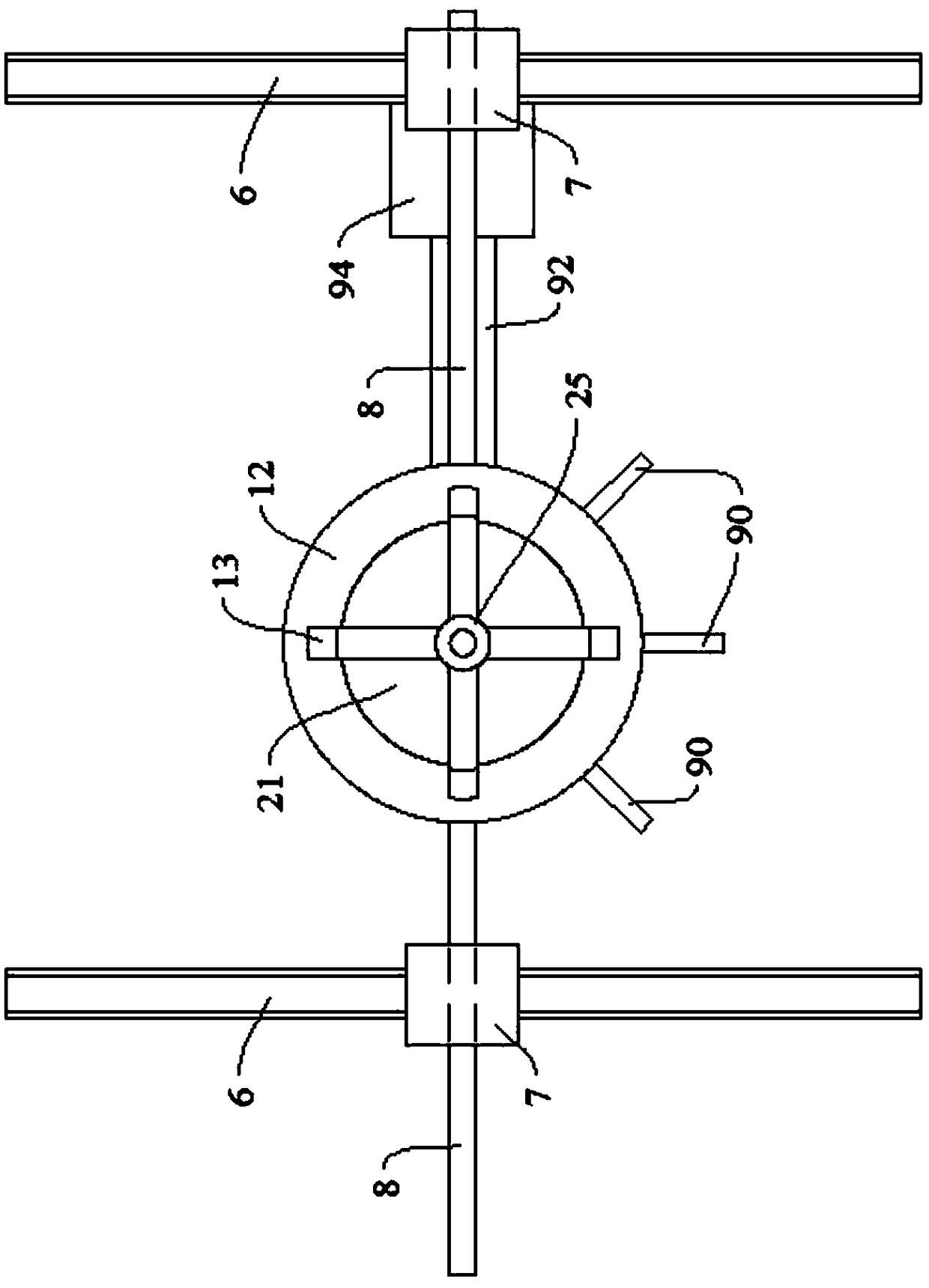

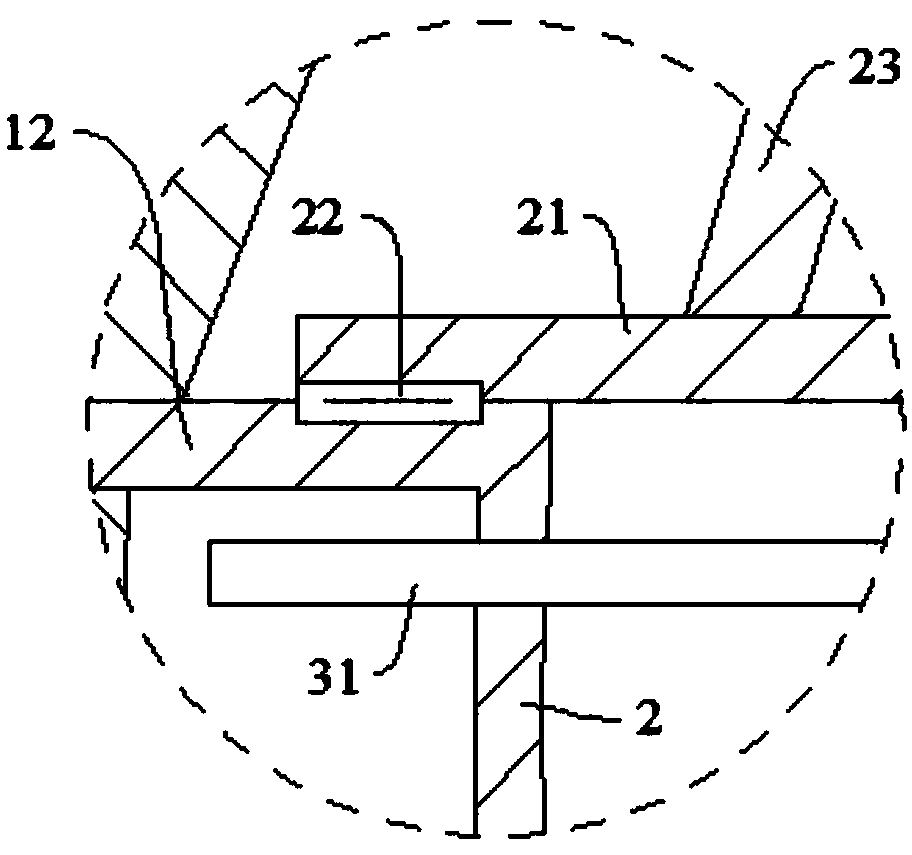

Image

Examples

Embodiment Construction

[0035] A kind of soil conditioner production technology, comprises the following steps:

[0036] Step 1: Preliminarily dehydrate the waste residue after lime nitrogen and hydrogen sulfide to synthesize thiourea until the water content is 40-45%, then send it to the stirring equipment, add magnesium sulfate, zinc sulfate, copper sulfate, manganese sulfate, iron sulfate powder, the resulting The magnesium sulfate, zinc sulfate, copper sulfate, manganese sulfate and iron sulfate accounted for the total dry weight are respectively: 0.5~2%, 0.5~2%, 1~3%, 1~2%, 1~3%; add rice noodle soup Adjust the water content to 55-60%, and stir evenly;

[0037] The preparation method of the rice noodle soup is as follows: grind the rice into powder, add 25 to 35 times the volume of water and boil at 85 to 100°C for 20 to 30 minutes;

[0038] Step 2: Preliminary dehydration, drying and grinding of the waste residue after synthesis of thiourea from lime nitrogen and hydrogen sulfide, the mass fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com