Preparation method of flame-retardant anti-static cable material

A flame retardant and antistatic cable technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of loss of life and property, obstruction of safe evacuation and fire extinguishing work, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

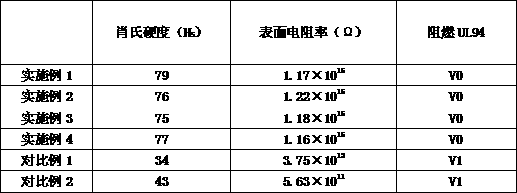

Examples

Embodiment 1

[0022] (1) 15 parts of polyvinyl chloride, 12 parts of polyethylene wax, 7 parts of polyethylene terephthalate, 5 parts of diethylene glycol dibenzoate, 5 parts of dodecyl alcohol ester, dimethyl 10 parts of oxymethane, 4 parts of sodium p-toluene sulfinate, 1 part of trioctyl citrate, 2 parts of 1-phenyl-1-cyanocyclopentane, 2 parts of diacrylaldehyde pentaerythritol, organic phosphite 1 part, 1 part of methyl trifluoromethanesulfonate, 1 part of diammonium phosphate, and 2 parts of ammonium chloride are mixed, added to the 15% sodium citrate solution preheated to 55 ° C, stirred evenly, and injected into banbury together machine, the temperature is raised to 660°C, the heating rate is 60°C / min, the high temperature reaction is 3h, and the temperature is lowered to 350°C for later use;

[0023] (2) Mix 3 parts of vinyltriethoxysilane, 1 part of benzyl silicone oil, 4 parts of sodium metabisulfite, 2 parts of cyclosiloxane fatty ester, 5 parts of dimethyl phthalate, 1 part of ...

Embodiment 2

[0029] (1) 20 parts of polyvinyl chloride, 16 parts of polyethylene wax, 9 parts of polyethylene terephthalate, 7 parts of diethylene glycol dibenzoate, 8 parts of didodecyl alcohol ester, dimethyl 12 parts of oxymethane, 6 parts of sodium p-toluene sulfinate, 2 parts of trioctyl citrate, 2 parts of 1-phenyl-1-cyanocyclopentane, 3 parts of diacrylaldehyde pentaerythritol, organic phosphite 1 part, 1 part of methyl trifluoromethanesulfonate, 2 parts of diammonium phosphate, and 3 parts of ammonium chloride are mixed, added to the 15% sodium citrate solution preheated to 55 °C, stirred evenly, and injected into banburying together machine, the temperature is raised to 670°C, the heating rate is 60°C / min, the high temperature reaction is 4h, and the temperature is lowered to 350°C for later use;

[0030] (2) Mix 3 parts of vinyltriethoxysilane, 1 part of benzyl silicone oil, 4 parts of sodium metabisulfite, 2 parts of cyclosiloxane fatty ester, 5 parts of dimethyl phthalate, 1 pa...

Embodiment 3

[0036] (1) 25 parts of polyvinyl chloride, 22 parts of polyethylene wax, 15 parts of polyethylene terephthalate, 9 parts of diethylene glycol dibenzoate, 12 parts of dodecyl alcohol ester, dimethyl 14 parts of oxymethane, 8 parts of sodium p-toluene sulfinate, 3 parts of trioctyl citrate, 3 parts of 1-phenyl-1-cyanocyclopentane, 4 parts of diacrylaldehyde pentaerythritol, organic phosphite 2 parts, 2 parts of methyl trifluoromethanesulfonate, 3 parts of diammonium phosphate, and 4 parts of ammonium chloride are mixed, added to the 15% sodium citrate solution preheated to 55 °C, stirred evenly and injected into banburying together machine, the temperature is raised to 720°C, the heating rate is 60°C / min, the high temperature reaction is 5h, and the temperature is lowered to 350°C for standby;

[0037] (2) Mix 3 parts of vinyltriethoxysilane, 1 part of benzyl silicone oil, 4 parts of sodium metabisulfite, 2 parts of cyclosiloxane fatty ester, 5 parts of dimethyl phthalate, 1 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com