Preparation method of probiotic granules being resistant to acid and bile salt

A technology of probiotics and bile salt resistance, which is applied in the field of probiotics and can solve the problems of loss of probiotic effect, loss of activity, and failure to meet the requirements for the effective amount released by the host intestine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

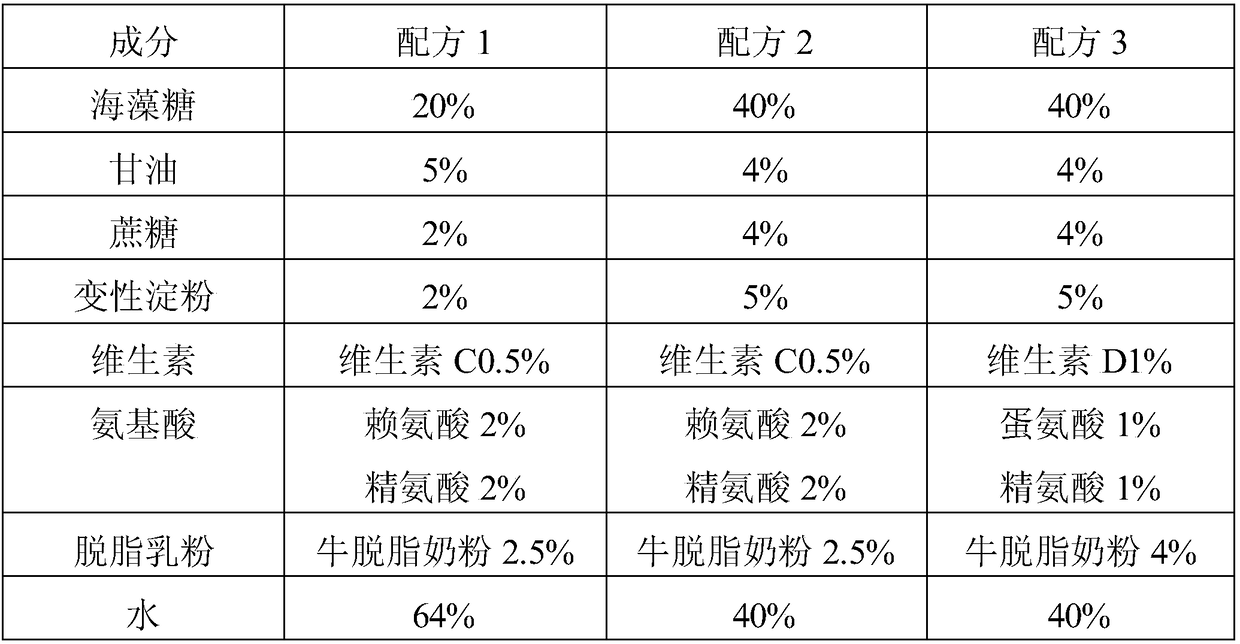

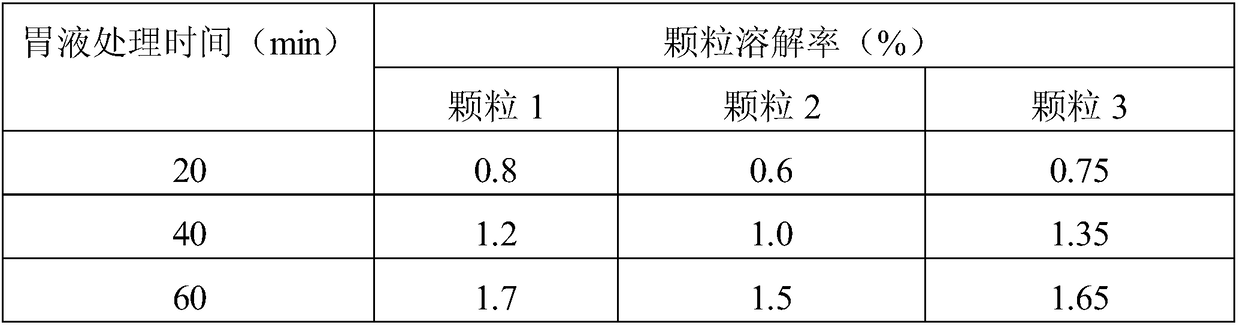

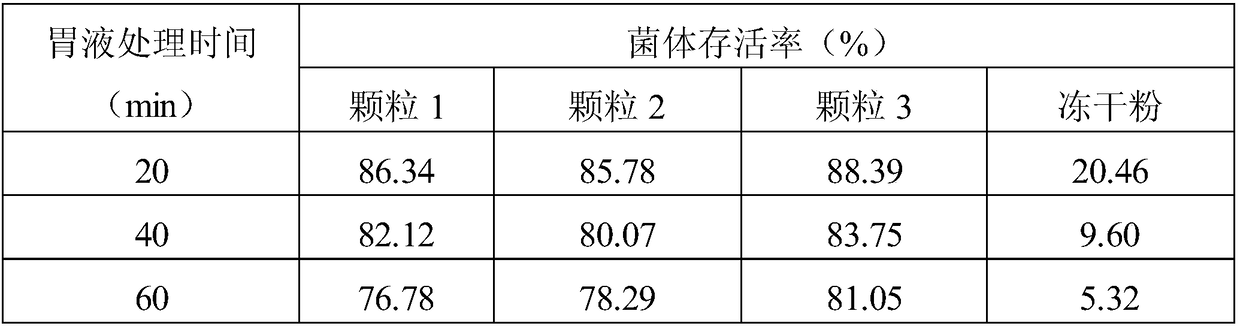

[0031] This embodiment uses Lactobacillus acidophilus as an example to provide a method for preparing acid-resistant and bile-resistant probiotic particles, and detecting the effect of different protective agents on the acid and bile-resistant properties of probiotic particles, including the following steps:

[0032] S1. Configure the protective agent solution, and cool to room temperature for use after sterilization, and the substances used can meet the food inspection standards; configure the sodium alginate colloidal liquid with a mass concentration of 5%, and cool to room temperature for use after sterilization;

[0033] S2. Mix the Lactobacillus acidophilus sludge and the protective agent solution at a ratio of 1:1, and stir slowly for 30 minutes to form an emulsion;

[0034] S3. Add the emulsion to the prepared colloidal liquid at a ratio of 2:1, stir to make it evenly mixed, and slowly stir for 5 minutes to form a fungal gum mixture;

[0035] S4. Slowly inject the bacterial gum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com