Preparation method for biomass charcoal/copper magnesium aluminum ternary metal hydroxide nitrogen-phosphorus-removing material

A biochar and hydroxide technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as low adsorption performance, unstable effect, and low removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

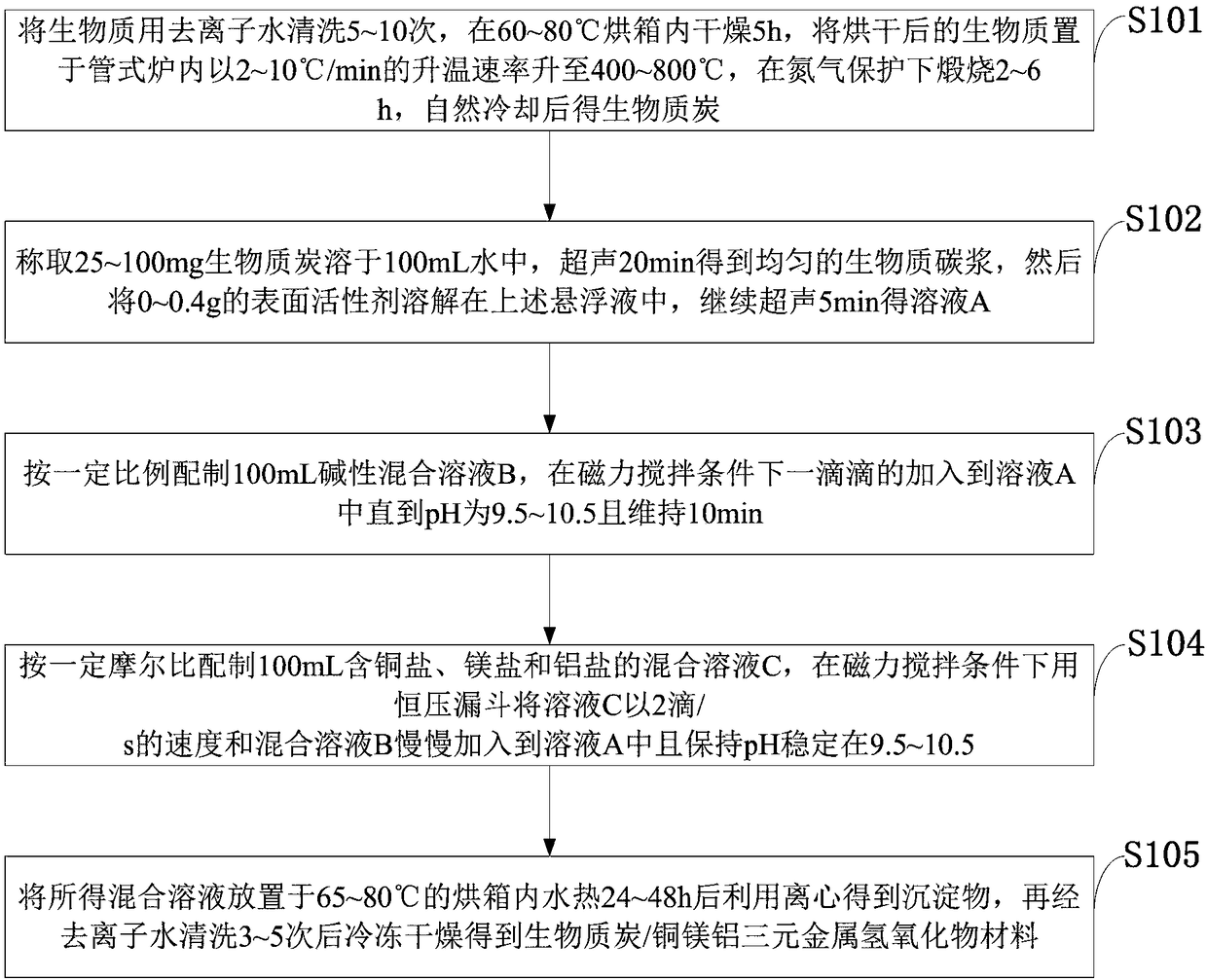

[0024] Such as figure 1 As shown, the preparation method of the biochar / copper-magnesium-aluminum ternary metal hydroxide nitrogen and phosphorus removal material provided by the embodiment of the present invention includes the following steps:

[0025] S101: Wash the biomass with deionized water for 5 to 10 times, dry it in an oven at 60 to 80°C for 5 hours, place the dried biomass in a tube furnace at a rate of 2 to 10°C / min to Calcination at 400-800°C for 2-6 hours under the protection of nitrogen, and natural cooling to obtain biochar;

[0026] S102: Weigh 25-100 mg of biochar and dissolve it in 100 mL of water, sonicate for 20 minutes to obtain a uniform biochar slurry, then dissolve 0-0.4 g of surfactant in the suspension, and continue to sonicate for 5 minutes to obtain solution A;

[0027]S103: Prepare 100mL alkaline mixed solution B according to a certain ratio, and add it drop by drop into solution A under magnetic stirring until the pH is 9.5-10.5 and maintain for...

Embodiment 1

[0033] a) Cut the bamboo into pieces and wash them with deionized water for 5 times, and dry them in an oven at 60°C for 5 hours. Put the dried biomass in a tube furnace and increase the temperature to 400°C at a rate of 2°C / min. Calcined for 2 hours under the protection of nitrogen, and naturally cooled to obtain biochar.

[0034] b) Weigh 25 mg of biochar and dissolve it in 100 mL of water, and sonicate for 20 minutes to obtain a uniform biochar slurry to obtain solution A.

[0035] c) Press [OH - ] / [CO 3 2- ] = 3.2, [CO 3 2- ] / [Al 3+ ] = 2 to prepare 100 mL of mixed solution B of sodium carbonate and sodium hydroxide, and added drop by drop to solution A under magnetic stirring until the pH was 9.5 and maintained for 10 min.

[0036] d) Prepare 100mL mixed solution C of copper chloride, magnesium chloride and aluminum chloride according to the molar ratio of 0.5:2.5:1, and mix solution C with the mixed solution B at a rate of 2 drops / s with a constant pressure funnel ...

Embodiment 2

[0039] a) The bamboo was cut into pieces and washed 6 times with deionized water, dried in an oven at 65°C for 5 hours, and the dried biomass was placed in a tube furnace to raise the temperature to 500°C at a rate of 4°C / min. Calcined for 3 hours under the protection of nitrogen, and naturally cooled to obtain biochar.

[0040] b) Weigh 35 mg of biochar and dissolve it in 100 mL of water, sonicate for 20 minutes to obtain a uniform biochar slurry, then dissolve 0.1 g of benzenesulfonic acid in the above suspension, and continue to sonicate for 5 minutes to obtain solution A.

[0041] c) Press [OH - ] / [CO 3 2- ] = 3.2, [CO 3 2- ] / [Al 3+ ] = 2 to prepare 100 mL of mixed solution B of sodium carbonate and sodium hydroxide, and added drop by drop to solution A under magnetic stirring until the pH was 9.5 and maintained for 10 min.

[0042] d) Prepare 100mL mixed solution C of copper nitrate, magnesium chloride and aluminum chloride according to the molar ratio of 0.5:2.5:1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com