High-mobility n-type ultrathin nano diamond film and preparation method thereof

A nano-diamond and high-mobility technology, applied in the field of high-mobility n-type ultra-thin nano-diamond film and its preparation, can solve problems such as poor electrical conductivity and affect the electrical performance of the film, and achieves a simple method, improved electrical performance, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

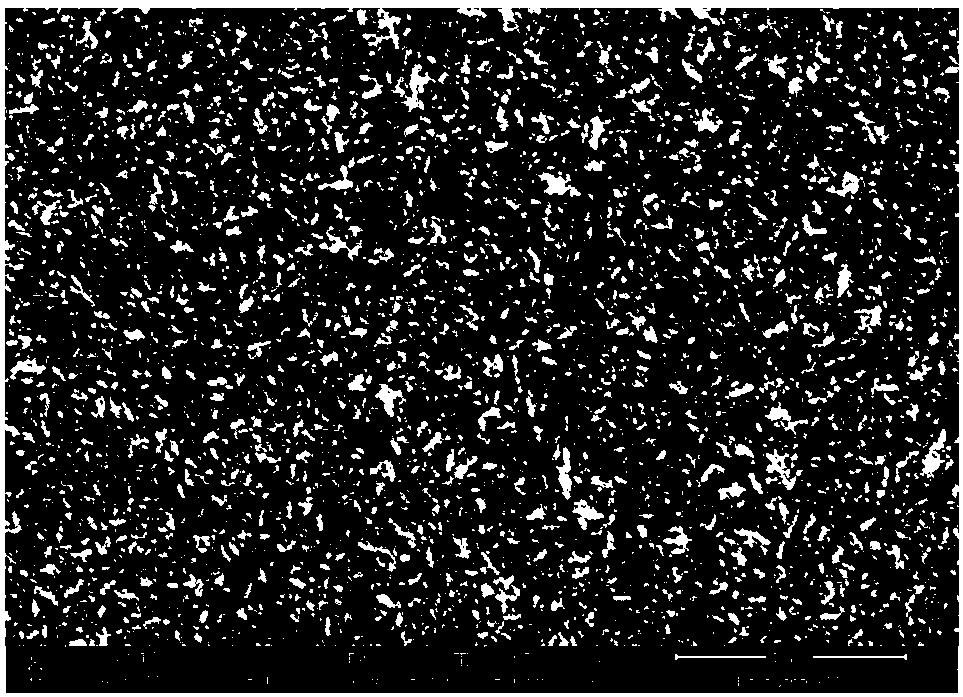

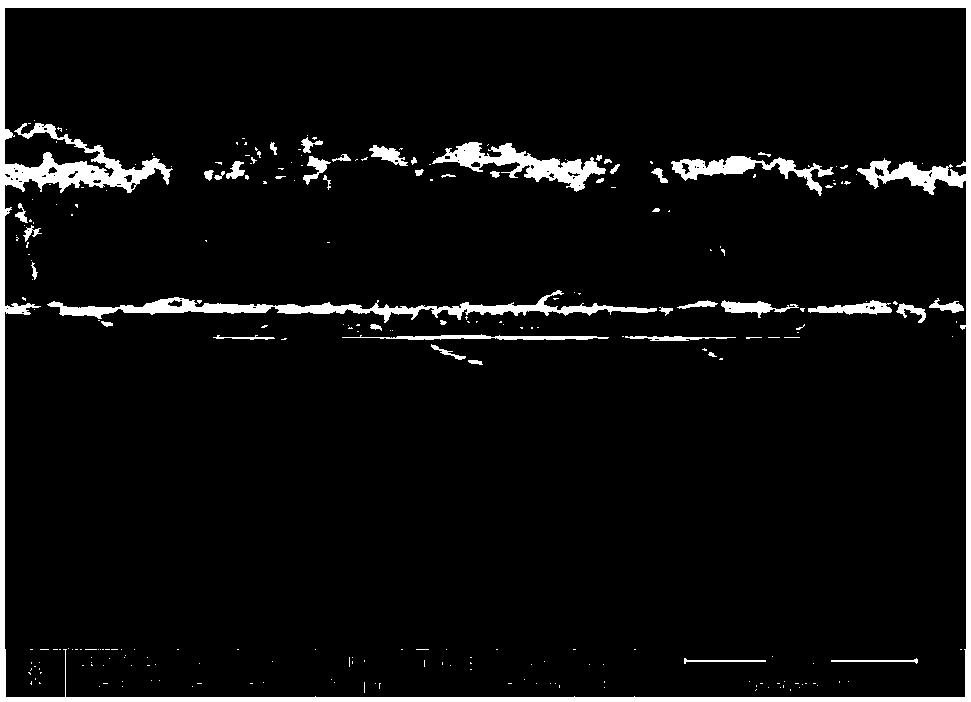

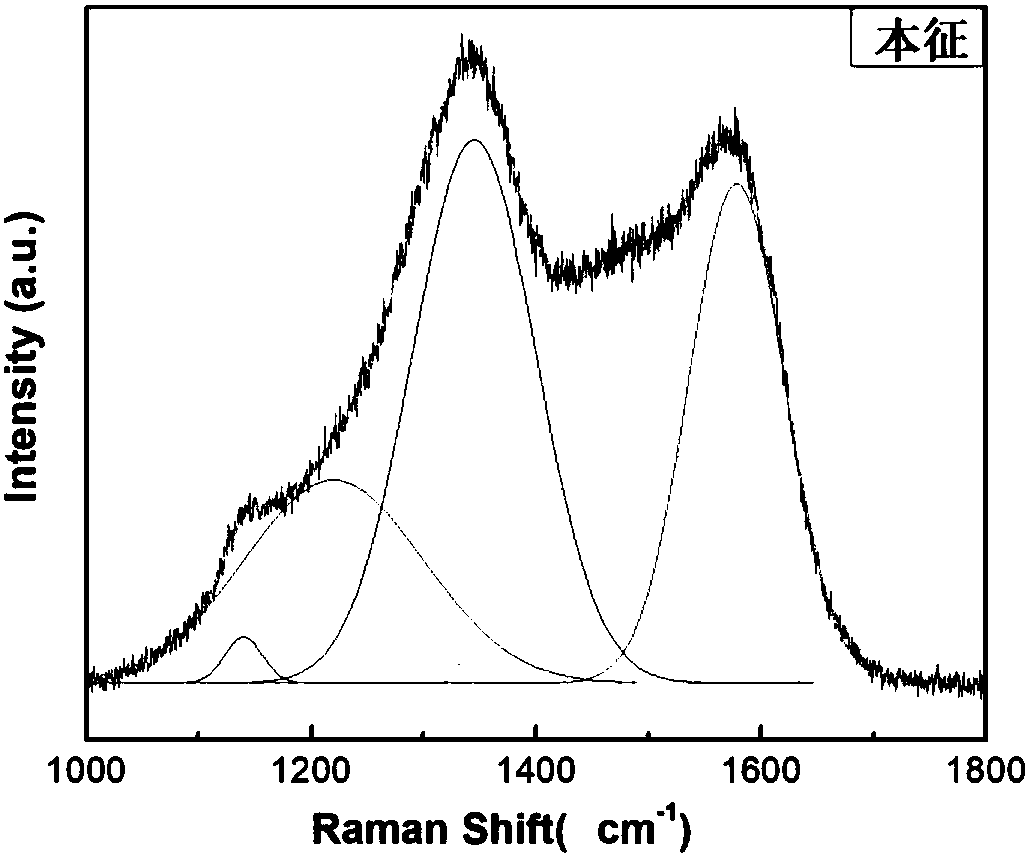

Image

Examples

Embodiment 1

[0028]The high-resistance silicon wafer was cleaned twice with acetone and dried as the substrate for depositing the AlN transition layer. The silicon wafer was placed on the reaction turntable of SPC-350 multi-target magnetron sputtering apparatus, with high-purity aluminum target as the target material, the reaction power was 100W, and the reaction pressure was 0.8KPa. The nitrogen flow rate is controlled at 17sccm and the argon flow rate is 5sccm through the flowmeter, and nitrogen and argon are introduced into the vacuum chamber, and the air pressure in the vacuum chamber is adjusted to the working pressure by turning the valve of the molecular pump, and the DC sputtering is turned on Slowly increase the power of the power supply, and after the Al target glows successfully, adjust the sputtering power to the required power and start sputtering. The sputtering time is 15 minutes, and the thickness of the AlN transition layer obtained is about 70 nm. The AlN-deposited high-...

Embodiment 2

[0037] The high-resistance silicon wafer was cleaned twice with acetone and dried as the substrate for depositing the AlN transition layer. The silicon wafer was placed on the reaction turntable of SPC-350 multi-target magnetron sputtering apparatus, with high-purity aluminum target as the target material, the reaction power was 100W, and the reaction pressure was 0.8KPa. The nitrogen flow rate is controlled at 17sccm and the argon flow rate is 5sccm through the flowmeter, and nitrogen and argon are introduced into the vacuum chamber, and the air pressure in the vacuum chamber is adjusted to the working pressure by turning the valve of the molecular pump, and the DC sputtering is turned on Slowly increase the power of the power supply, and after the Al target glows successfully, adjust the sputtering power to the required power and start sputtering. The sputtering time was 15 minutes, and an AlN transition layer with a thickness of 70 nm was obtained. The AlN-deposited high-r...

Embodiment 3

[0042]The high-resistance silicon wafer was cleaned twice with acetone and dried as the substrate for depositing the AlN transition layer. The silicon wafer was placed on the reaction turntable of SPC-350 multi-target magnetron sputtering apparatus, with high-purity aluminum target as the target material, the reaction power was 100W, and the reaction pressure was 0.8KPa. The nitrogen flow rate is controlled at 17sccm and the argon flow rate is 5sccm through the flowmeter, and nitrogen and argon are introduced into the vacuum chamber, and the air pressure in the vacuum chamber is adjusted to the working pressure by turning the valve of the molecular pump, and the DC sputtering is turned on Slowly increase the power of the power supply, and after the Al target glows successfully, adjust the sputtering power to the required power and start sputtering. The sputtering time is 15 minutes, and the thickness of the AlN transition layer obtained is 70 nm. The AlN-deposited high-resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com