Preparation method of graphene modified high-nickel-series anode material

A graphene modification, cathode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as outstanding safety problems, decreased cycle performance and rate performance, serious gas production in cells, etc., and achieve high electronic conductivity. The effect of improving the rate, improving the rate performance, and improving the processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

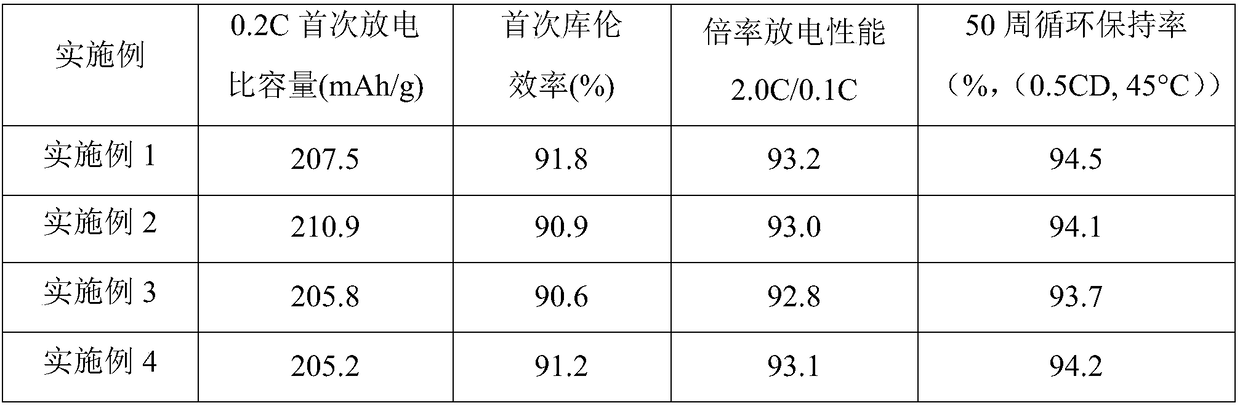

Examples

Embodiment 1

[0038] A method for preparing a graphene-modified high-nickel series positive electrode material, comprising the following steps:

[0039] 1) The median particle size (D 50 )=10μm battery-grade nickel-cobalt-manganese hydroxide high-nickel precursor (the molar content of nickel is 80%) and lithium hydroxide according to the molar ratio of lithium ions and total metal ions (Li:Metal) is 1.05:1 at high speed Mix evenly, take 3kg of the mixed material and put it into a refractory saggar, under an oxygen atmosphere, the oxygen purity is controlled at 99.5% (V / V), and calcined in a roller kiln at 700°C for 25 hours to obtain a high-nickel primary The roasted material is then mechanically pulverized and classified at a frequency of 22 Hz to obtain the primary pulverized material of nickel oxide, cobalt, manganese and lithium;

[0040] 2) Add 1g of polyvinylpyrrolidone (PVP) to 1100g of ethanol and stir evenly to form solution I, then add 100g of polyvinylidene fluoride (PVDF) into so...

Embodiment 2

[0044] A method for preparing a graphene-modified high-nickel series positive electrode material, comprising the following steps:

[0045] 1) will D 50 =15μm battery-grade nickel-cobalt-manganese hydroxide high-nickel precursor (the molar content of nickel is 85%) and lithium carbonate are mixed at a high speed according to the Li:Metal molar ratio of 1.03:1, and the mixed material is packed in 3kg Put it into a refractory sagger, when the oxygen purity is controlled at 99.5%, calcined in a roller kiln at 800°C for 22 hours to obtain a high-nickel primary roasted material, and then mechanically pulverize and classify at a frequency of 18Hz to obtain a nickel-cobalt-manganese-lithium primary crushed material ;

[0046] 2) Add 1g of PVP to 1100g of ethanol and stir evenly to form solution I, then add 100g of PVDF to solution I and disperse evenly to form solution II, and finally add 80g of D 50 Graphene with a diameter of 5 μm is added to the solution II to disperse evenly to ...

Embodiment 3

[0050] A method for preparing a graphene-modified high-nickel series positive electrode material, comprising the following steps:

[0051] 1) will D 50 =10 μm battery-grade nickel-cobalt-manganese hydroxide high-nickel precursor (the molar content of nickel is 80%) and lithium hydroxide are uniformly mixed at a high speed according to the Li:Metal molar ratio of 1.05:1, and the mixed material takes 3kg Put it into a refractory sagger, and when the oxygen purity is controlled at 99.5%, calcinate in a roller kiln at 700°C for 25 hours to obtain a high-nickel primary roasted material, and then mechanically pulverize and classify at a frequency of 20Hz to obtain primary pulverization of nickel oxide, cobalt, manganese, and lithium material;

[0052] 2) First add 1g of polyethylene glycol octylphenyl ether into 1100g of deionized water and stir to form solution I, then add 75g of polyvinyl alcohol (PVA) to solution I to disperse evenly to form solution II, and finally add 70g of D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com