A kind of osteoinductive collagen-based composite hydrogel and preparation method thereof

A composite hydrogel, osteoinductive technology, applied in pharmaceutical formulations, prostheses, drug delivery, etc., can solve the problems of insufficient osteoinductivity, poor compatibility between the organic phase and particle-bone interface, etc., and achieve excellent tissue induction. , good spatial stability, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

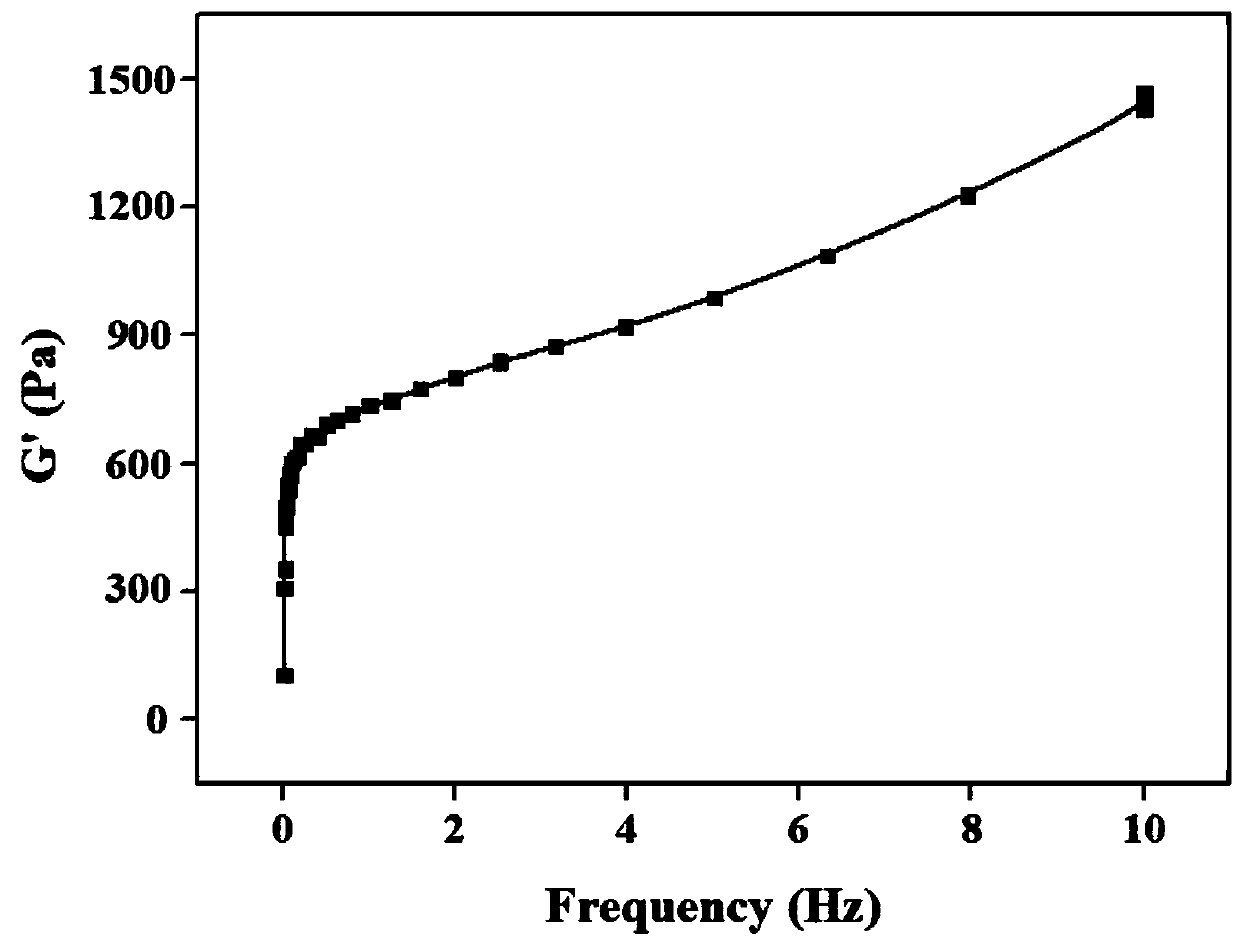

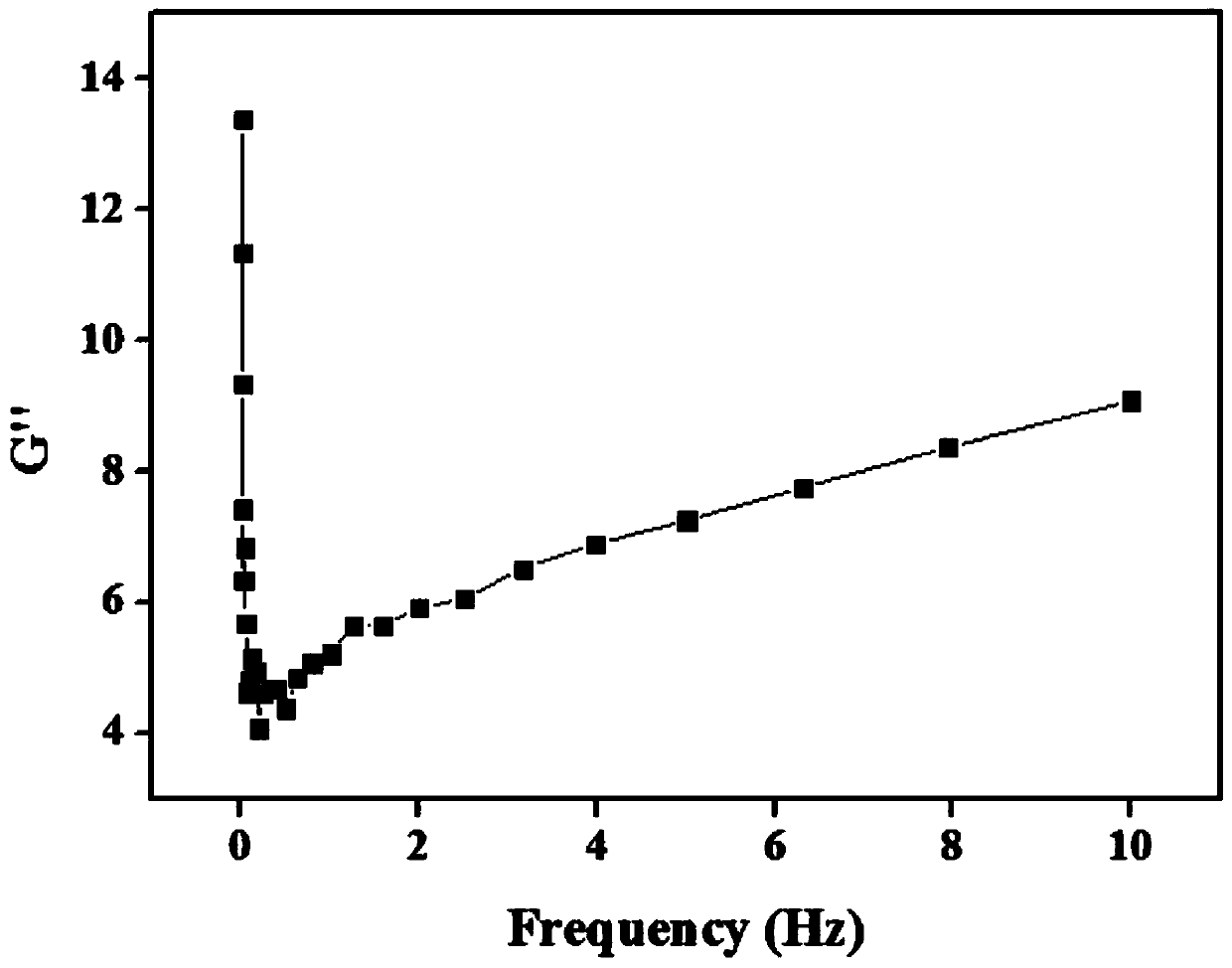

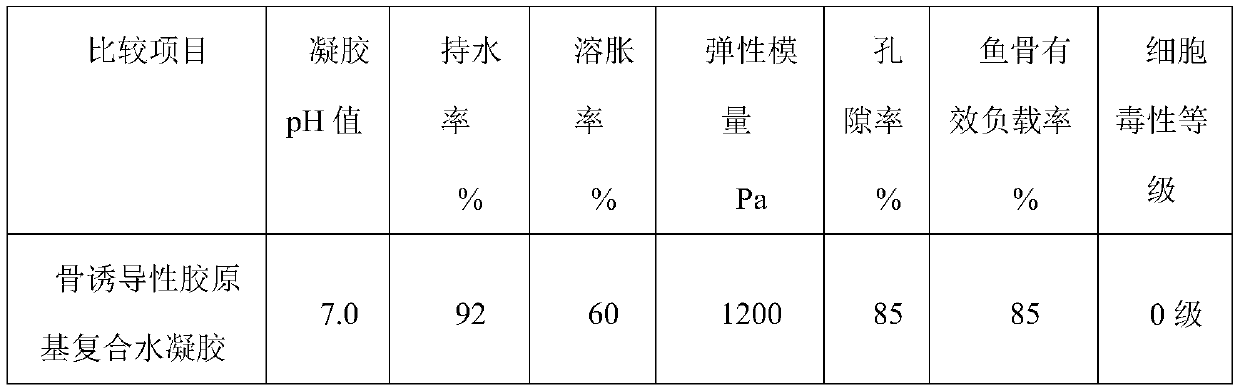

[0031] Use 0.1mol / L, pH 2.0 acetic acid-sodium acetate solution to dissolve pigskin collagen, stir well at 4°C to help dissolve and disperse, obtain a collagen solution with a concentration of 15mg / mL, and then use 0.1mol / L NaOH solution Adjust the pH value of the solution to 7.0, and then incubate at 30°C for 4 hours to obtain a skin collagen hydrogel substrate; soak the prepared skin collagen hydrogel substrate at 20°C 5 wt% of the dry weight of the collagen hydrogel base material) was reacted in a chemical modifier for 8 hours. Subsequent addition of dopamine and H 2 o 2 , the dosage of dopamine is 5wt% of skin collagen hydrogel base material dry weight, H 2 o 2 The dosage is 0.5% by weight of dopamine, and the reaction is 3 hours. Then add nano-tilapia bones (the amount is 5wt% of the dry weight of the skin collagen hydrogel substrate), adjust the loading temperature to 30° C., and the pH to 7.0. After reacting for 4 hours, use ultrapure water to fully wash 3 times, an...

Embodiment 2

[0035] Use 0.1mol / L acetic acid-sodium acetate solution with a pH of 2.0 to dissolve sheepskin collagen, stir well at 10°C to help dissolve and disperse, and obtain a collagen solution with a concentration of 10mg / mL, and then use 0.1mol / L NaOH solution to adjust The pH value of the solution was brought to 7.5, and then incubated at a constant temperature at 37°C for 8h to obtain a skin collagen hydrogel substrate; the prepared skin collagen hydrogel substrate was immersed at 30°C in a solution containing oxidized hyaluronic acid (amount of 6wt% of the dry weight of the hydrogel base material) was reacted in the chemical modifier for 8 hours. Subsequent addition of dopamine and H 2 o 2 , the amount of dopamine is 10wt% of dry weight of skin collagen hydrogel substrate, H 2 o 2 The dosage is 1.0wt% of dopamine weight, and the reaction is 3h. Then add nano-salmon fish bones (the amount is 10wt% of the dry weight of the skin collagen hydrogel substrate), adjust the loading te...

Embodiment 3

[0037] Use 0.15mol / L, pH 2.5 acetic acid-sodium acetate solution to dissolve bovine skin collagen, stir well at 4°C to help dissolve and disperse, obtain a collagen solution with a concentration of 5mg / mL, and then use 0.1mol / L NaOH solution to adjust The pH value of the solution was brought to 8.0, and then incubated at a constant temperature at 37°C for 6h to obtain a skin collagen hydrogel substrate; the prepared skin collagen hydrogel substrate was immersed at 30°C 5wt% of the dry weight of the hydrogel base material) was reacted in the chemical modifier for 8h. Subsequent addition of dopamine and H 2 o 2 , the amount of dopamine is 6wt% of the dry weight of the skin collagen hydrogel substrate, H 2 o 2 The dosage is 2.0wt% by weight of dopamine, and the reaction takes 2 hours. Then add nano-grass carp fish bones (the amount is 8wt% of the dry weight of the skin collagen hydrogel substrate), adjust the load temperature to 30 ° C, and pH to 6.5. After reacting for 12 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com