Method of using pulsed laser deposition to prepare independent dispersed cobalt ferrite nano column

A pulsed laser deposition, cobalt ferrite nanotechnology, applied in evaporation applications, applications from magnetic films to substrates, inductor/transformer/magnet manufacturing, etc. It is suitable for industrial applications and other problems, and achieves the effects of excellent structural stability, good heat transfer, and high magnetostrictive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

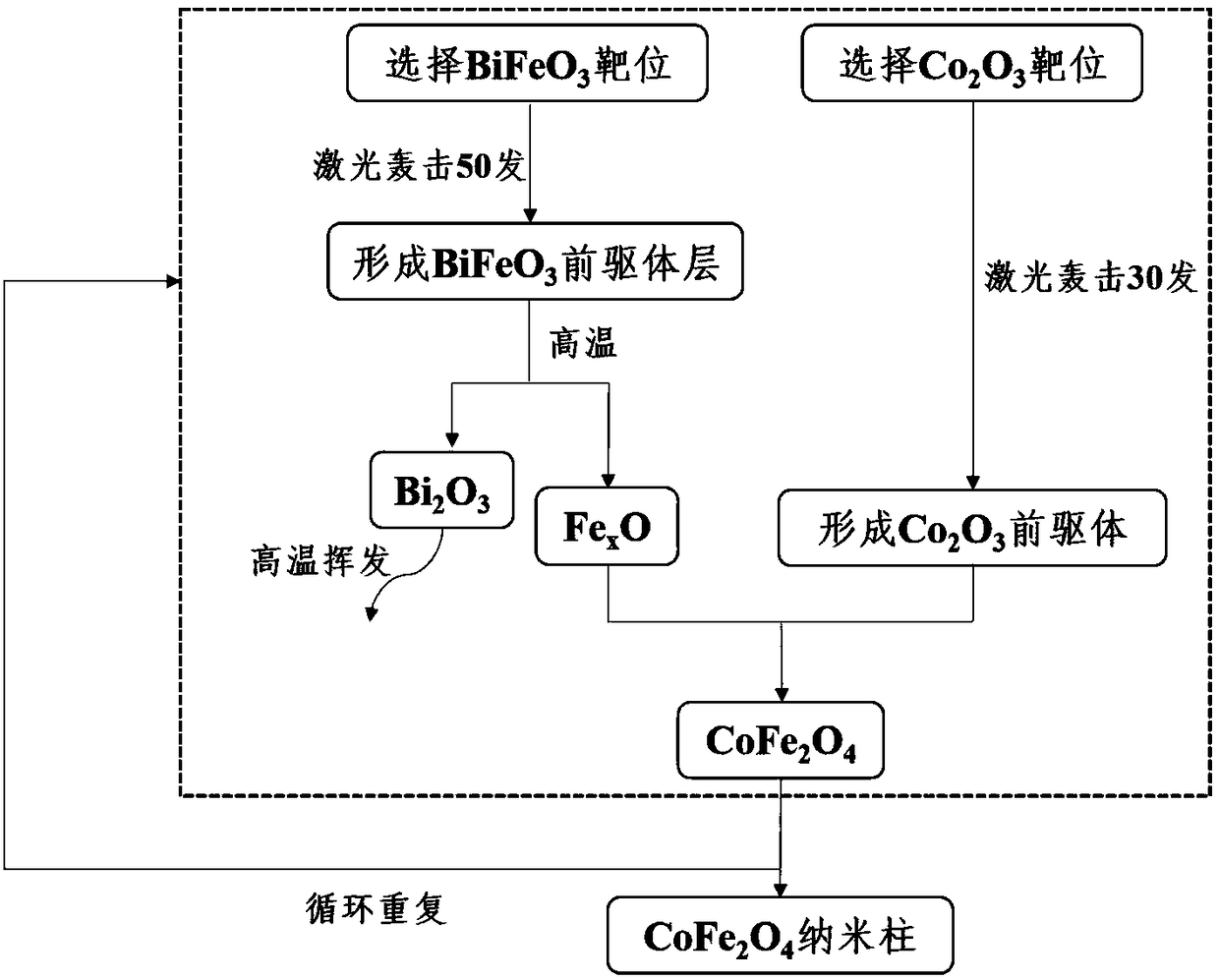

[0052] A method for preparing independently dispersed CFO nanocolumns on STO (100) substrates with a PLD system, comprising the following steps:

[0053] (1) Select the STO (100) substrate and pretreat it, specifically including the following steps:

[0054] a. Put the STO (100) substrate into the acetone (CH 3 COCH 3 ) in a beaker, and then fill the periphery of the beaker with foam, put it into an ultrasonic cleaner filled with deionized water, float the beaker in deionized water, and ultrasonically clean it at 55°C for 10 minutes;

[0055] b. Then immerse the STO (100) substrate in absolute ethanol, and ultrasonically clean it for 2 minutes;

[0056] c. Then immerse the STO (100) substrate in deionized water and ultrasonically clean it for 2 minutes;

[0057] d. Finally, use high-purity nitrogen (N 2 , 99.999%) to dry the STO (100) substrate.

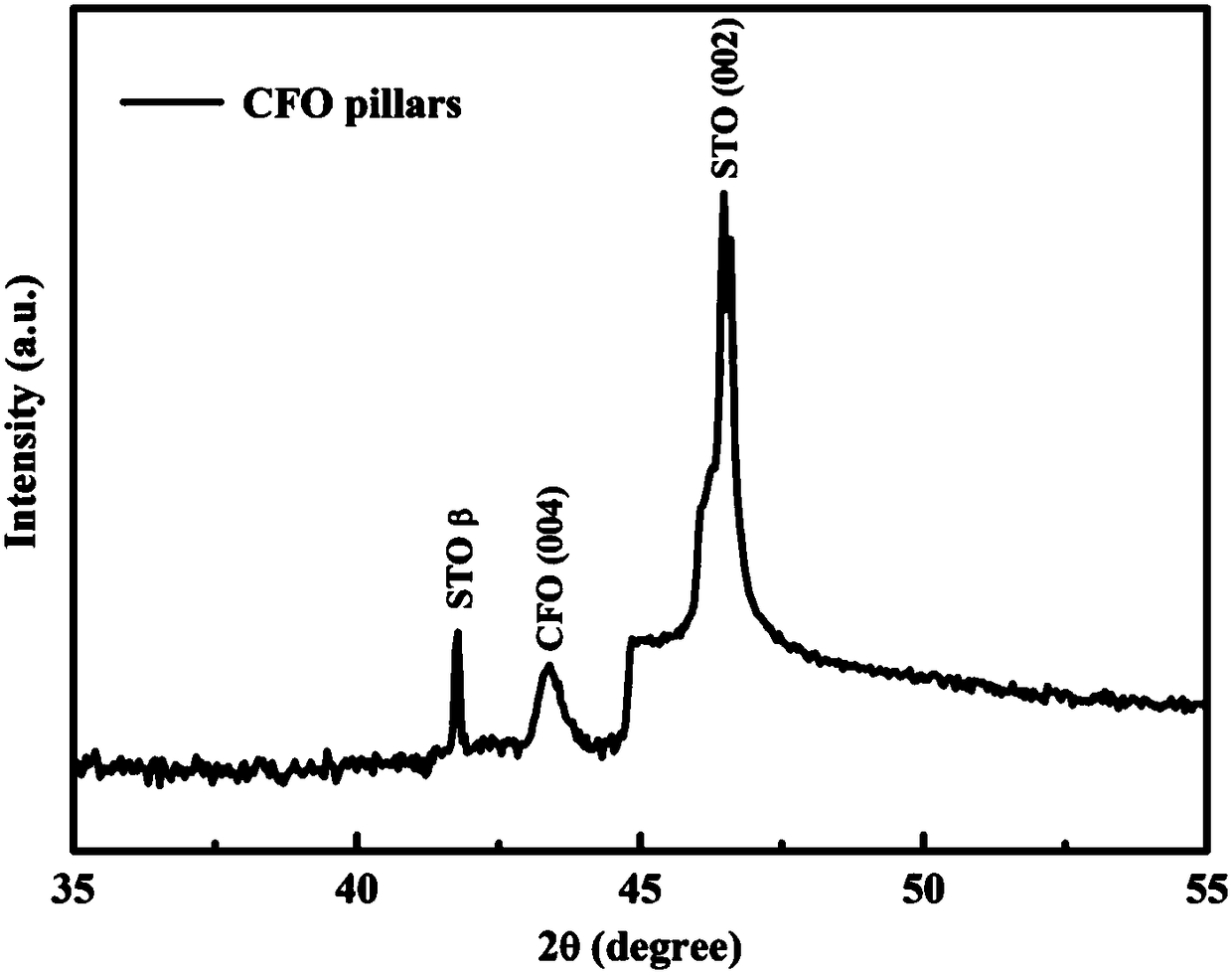

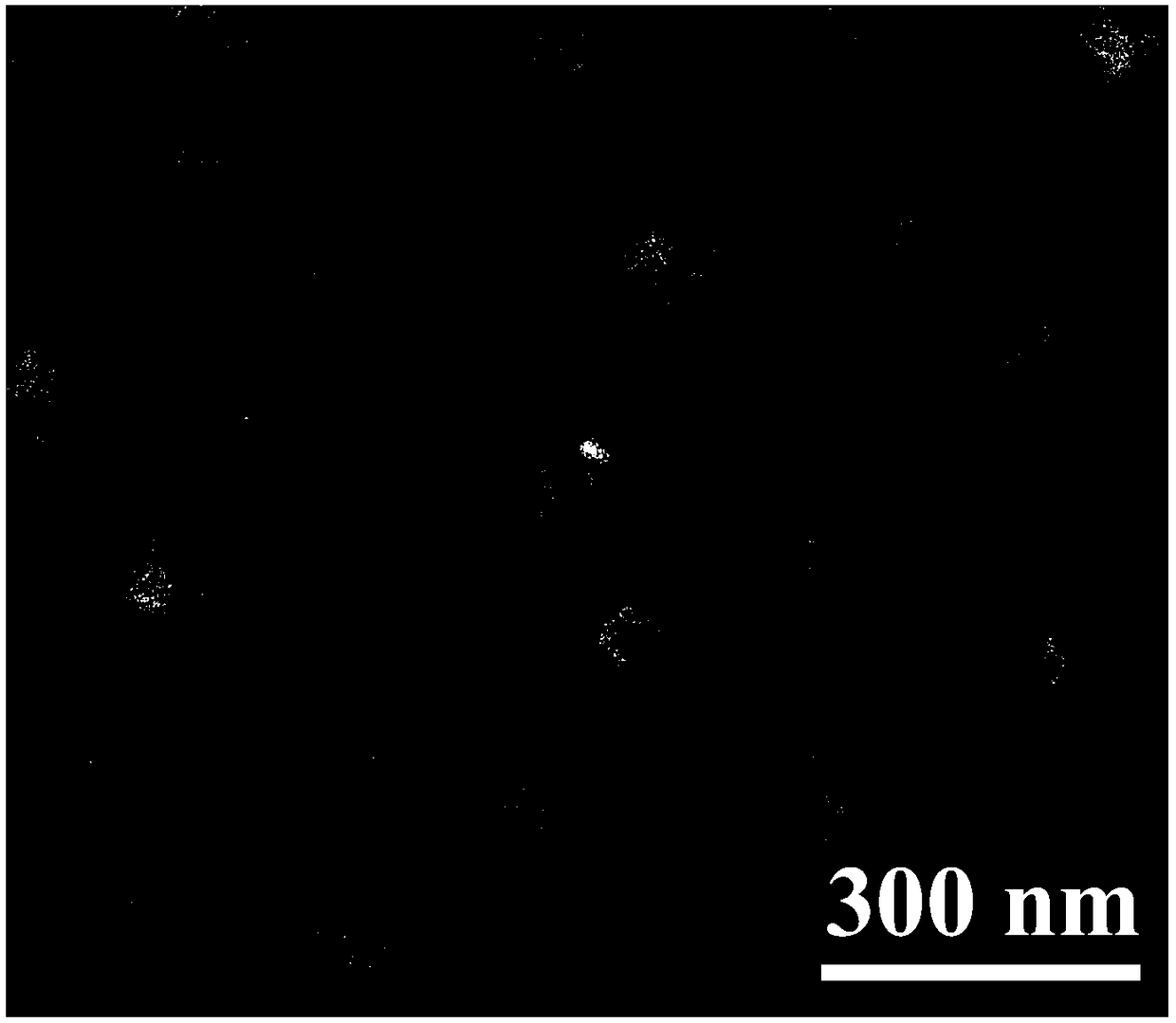

[0058] (2) Using PLD system to prepare CFO nanocolumns on STO (100) substrates, select the laser as KrF (λ=248nm) excimer lase...

Embodiment 2

[0066] A method for preparing independently dispersed CFO nanocolumns on STO (110) substrates with PLD system, comprising the following steps:

[0067] (1) Select the STO (110) substrate and pretreat it, specifically including the following steps:

[0068] a. Put the STO (110) substrate into the acetone (CH 3 COCH 3 ) in a beaker, and then fill the periphery of the beaker with foam, put it into an ultrasonic cleaner filled with deionized water, float the beaker in deionized water, and ultrasonically clean it at 55°C for 10 minutes;

[0069] b. Then immerse the STO (110) substrate in absolute ethanol, and ultrasonically clean it for 2 minutes;

[0070] c. Then immerse the STO (110) substrate in deionized water and ultrasonically clean it for 2 minutes;

[0071] d. Finally, use high-purity nitrogen (N 2 , 99.999%) to dry the STO (110) substrate.

[0072] (2) Use PLD system to prepare CFO nanocolumns on STO (110) substrates, select the laser as KrF (λ=248nm) excimer laser, a...

Embodiment 3

[0080] A method for preparing independently dispersed CFO nanocolumns on STO(111) substrates with PLD system, comprising the following steps:

[0081] (1) Select the STO (111) substrate and pretreat it, specifically including the following steps:

[0082] a. Put the STO (111) substrate into the acetone (CH 3 COCH 3 ) in a beaker, and then fill the periphery of the beaker with foam, put it into an ultrasonic cleaner filled with deionized water, float the beaker in deionized water, and ultrasonically clean it at 55°C for 10 minutes;

[0083] b. Then immerse the STO (111) substrate in absolute ethanol, and ultrasonically clean it for 2 minutes;

[0084] c. Then immerse the STO (111) substrate in deionized water and ultrasonically clean it for 2 minutes;

[0085] d. Finally, use high-purity nitrogen (N 2 , 99.999%) to dry the STO (111) substrate.

[0086] (2) Use PLD system to prepare CFO nanocolumns on STO (111) substrates, select the laser as KrF (λ=248nm) excimer laser, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com