Preparation method of milk powder for infants

A milk powder and infant technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of unbalanced nutrient combination, inability to digest and absorb infants, and poor sensitization treatment effect, so as to achieve easy precipitation and reduce allergies. Originality, high affinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

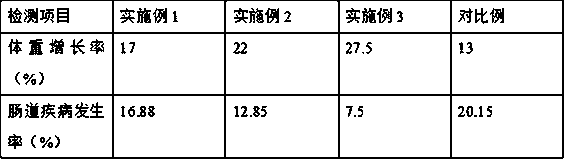

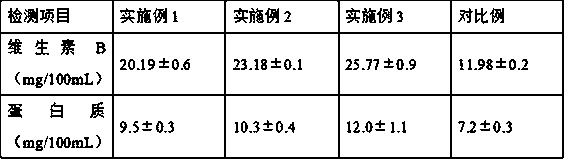

Examples

preparation example Construction

[0028] A method for preparing baby milk powder, the preparation method comprising the steps of:

[0029] (1) According to the mass ratio of 1~2:10~15, add 0.5mol / L calcium chloride solution into the skim milk, the temperature is 25~30℃, adjust the pH to 10~11, and carry out at 4000~5000r / min Centrifuge for 8~10min to get supernatant, adjust the pH to 3~4, and then centrifuge at 4000~5000r / min for 8~10min to get sediment. Dissolve at 25°C, adjust the pH value to 7~8, let stand for 1~2h, filter to obtain the filtrate;

[0030](2) Filter the egg white with double-layer gauze to obtain the filtrate, mix the filtrate and distilled water according to the mass ratio of 1:3~4, and stir at 200~300r / min for 4~5min, add 1~2% of the filtrate mass sodium chloride, then stirred at 100~200r / min for 3~4min, adjusted the pH value to 9~10, then added lysozyme seed crystals with 20~30% of the filtrate quality, and stood at a temperature of 3~4°C until the crystallization was complete Finally, ...

Embodiment 1

[0034] Skim milk was purchased from Meiji Dairy Co., Ltd.

[0035] Vegetable oil is obtained by mixing soybean oil, corn oil, and high oleic sunflower oil in a mass ratio of 1:1:1:1.

[0036] Multivitamins are calculated in parts by weight, take 100 parts of vitamin A, 80 parts of vitamin B, 50 parts of vitamin D, 6 parts of vitamin C, 6 parts of folic acid, 5 parts of vitamin K, 1 part of biotin, 1 part of vitamin E, 1 1 part of niacin is mixed to obtain a multivitamin.

[0037] Composite minerals are calculated in parts by weight, taking 400 parts of potassium, 300 parts of calcium, 200 parts of copper, 150 parts of phosphorus, 125 parts of sodium, 60 parts of iodine, 30 parts of magnesium, 10 parts of manganese, 3 parts of iron and 3 parts of zinc. Mix to get compound trace elements.

[0038] The liquid medium is calculated in parts by weight, and 30 parts of water, 10 parts of yeast extract, 10 parts of glucose, 5 parts of tryptone, 5 parts of soy peptone, 4 parts of sod...

Embodiment 2

[0046] Skim milk was purchased from Meiji Dairy Co., Ltd.

[0047] Vegetable oil is obtained by mixing soybean oil, corn oil, and high oleic sunflower oil in a mass ratio of 1:1:1:1.

[0048] Multivitamins are calculated in parts by weight. Take 150 parts of vitamin A, 90 parts of vitamin B, 60 parts of vitamin D, 8 parts of vitamin C, 7 parts of folic acid, 6 parts of vitamin K, 2 parts of biotin, 2 parts of vitamin E, 1 1 part of niacin is mixed to obtain a multivitamin.

[0049] Composite minerals are calculated in parts by weight, taking 500 parts of potassium, 350 parts of calcium, 250 parts of copper, 170 parts of phosphorus, 150 parts of sodium, 70 parts of iodine, 50 parts of magnesium, 12 parts of manganese, 7 parts of iron and 7 parts of zinc. Mix to get compound trace elements.

[0050] The liquid medium is calculated in parts by weight, and 35 parts of water, 12 parts of yeast extract, 12 parts of glucose, 6 parts of tryptone, 6 parts of soybean peptone, 5 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com