A controlled synthesis method of uranium oxide micro/nano crystals

A synthesis method and nanocrystal technology, applied in uranium dioxide, uranium oxide/hydroxide, nanotechnology, etc., can solve the problems of lack of high quality, limitation of micro-nano materials, etc., and achieve uniform size, good crystallinity, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1a. Under slow electromagnetic stirring, dissolve uranyl acetate into a mixed solution of acetone and water, the volume percentage of acetone is 50%, to obtain solution I, and the concentration of uranyl ion in solution I is 1 mmol / L;

[0022] 1b. Add ammonia water to solution I, adjust the pH value to 9.5~11.0, and obtain solution II;

[0023] 1c. Transfer the solution II to a polytetrafluoroethylene reactor, react at 200°C for 72 hours, and naturally cool to room temperature to obtain a precipitate;

[0024] 1d. The precipitate is centrifuged and separated, and then washed with ethanol and acetone to obtain the product.

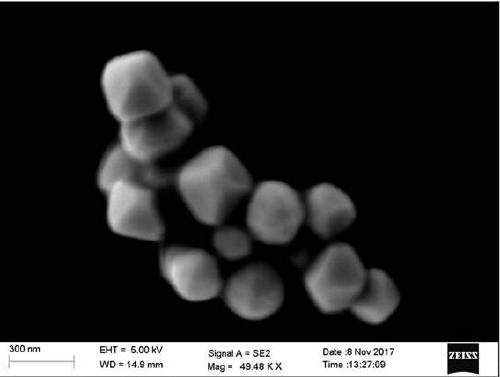

[0025] The phase of the product can be identified as pure UO2 by X-ray diffraction, and the crystallinity is >95%.

Embodiment 2

[0027] 2a. Under slow electromagnetic stirring, dissolve uranyl nitrate into a mixed solution of acetone and water, the volume percentage of acetone is 20%, to obtain solution I, and the concentration of uranyl ions in solution I is 10 mmol / L;

[0028] 2b. Adjust the pH value of solution I to 4.5 with ammonia water to obtain solution II;

[0029] 2c. Transfer the solution II to a polytetrafluoroethylene reactor, react at 160°C for 24 hours, and naturally cool to room temperature to obtain a yellow precipitate;

[0030] 2d. The precipitate is centrifuged and separated, and then washed with ethanol and acetone to obtain the product.

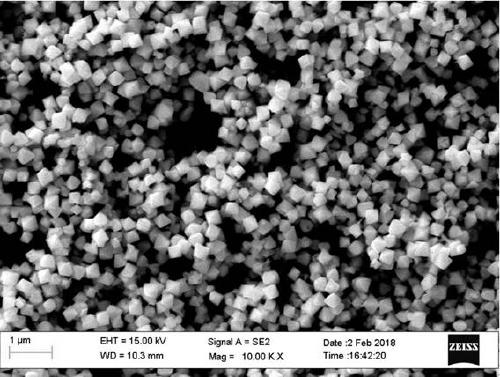

[0031] The phase of the product can be identified by X-ray diffraction as pure UO3·0.8H2O with a crystallinity of >95%. The shape of hexagonal microflakes was observed by scanning electron microscopy.

Embodiment 3

[0033] 3a. Under slow electromagnetic stirring, dissolve uranyl acetate into a mixed solution of acetone and water, the volume percentage of acetone is 50%, to obtain solution I, and the concentration of uranyl ion in solution I is 10mmol / L;

[0034] 3b. Add ammonia water to solution I, adjust the pH value to 7.5~8.5, and obtain solution II;

[0035] 3c. Transfer the solution II to a polytetrafluoroethylene reactor, react at 200°C for 20 hours, and naturally cool to room temperature to obtain a precipitate;

[0036] 3d. The precipitate is centrifuged and separated, and then washed with ethanol and acetone to obtain a product.

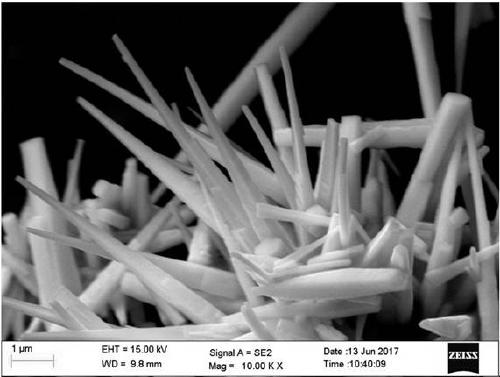

[0037] The phase of the product can be identified by X-ray diffraction as pure U3O8 with crystallinity>95%. Scanning electron microscope observed such as figure 1 The shape shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com