Uric acid-lowering marine fish oligopeptide and preparation method thereof

A marine fish oligopeptide and uric acid-lowering technology, which is applied in the preparation methods of peptides, chemical instruments and methods, peptides, etc., can solve the problems of general desalination effect, high cost, high energy consumption, etc., so as to relieve muscle pain and salinity. Less and more economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

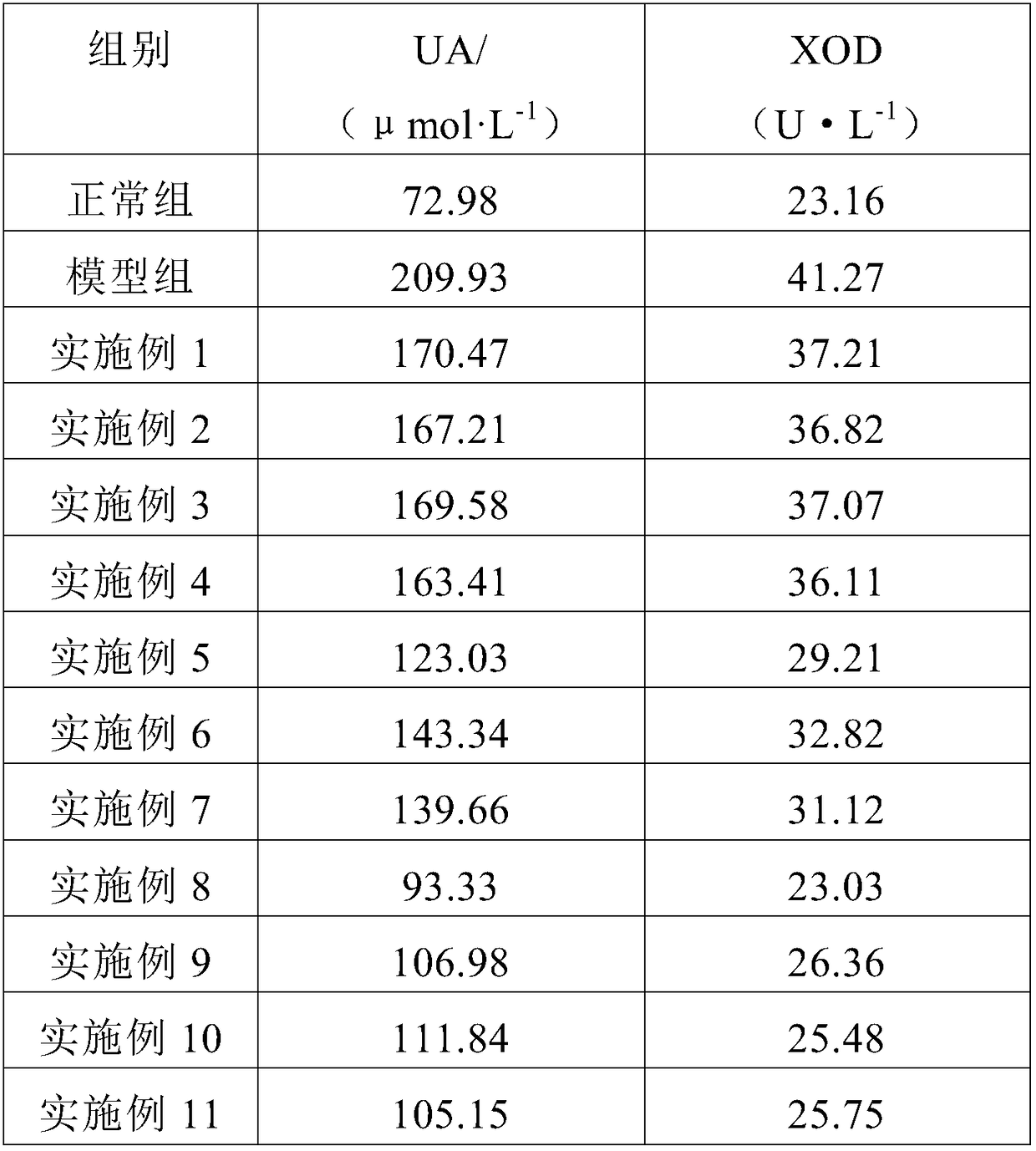

Examples

preparation example Construction

[0046] The preparation method of the enzyme activator is as follows: mix magnesium acetate and dimethyl carbonate at a mass ratio of 3:0.1, and stir at 500 r / min for 30 minutes at 35°C to obtain the enzyme activator.

[0047] Glucose, CAS number: 50-99-7, was purchased from Shandong Zibo Yufengyuan Sugar Co., Ltd.

[0048] Activated carbon powder, particle size 40 mesh, food grade, was purchased from Gongyi City Songshan Filter Material Activated Carbon Factory.

[0049] Aspergillus niger, model NY-3033, with an effective viable count of 15 billion CFU / g, was purchased from Jining Yuyuan Biotechnology Co., Ltd.

[0050] Yeast, with an effective viable count of 20 billion CFU / g, was purchased from Guangzhou Weiyuan Biotechnology Co., Ltd.

[0051] Bacillus subtilis, with an effective viable count of 10 billion CFU / g, was purchased from Cangzhou Fangyuan Bioengineering Co., Ltd.

[0052] 5000Da ultrafiltration membrane, made of PES, model MWCO500, purchased from General Electr...

Embodiment 1

[0060] A method for preparing uric acid-reducing marine fish oligopeptides, comprising the following steps:

[0061] Ⅰ. Remove the skin and bones of the marine fish and take the fish meat, wash the fish meat with 2°C cold water for 3 times, the mass ratio of cold water to fish meat for each washing is 2:1, let it stand for 4 minutes after each washing, and drain the water, Get pre-treated fish meat;

[0062] Ⅱ. Grinding the above-mentioned pretreated fish with a meat grinder, the production capacity of the meat grinder is 120kg / h, and the power is 0.55kw to obtain minced fish with a diameter of 8mm, according to the mass-volume ratio of 1:4 (g / mL) Add water to the obtained minced fish meat, place it in a homogenizer at 30°C and 1500r / min and stir for 30min to obtain a homogenate;

[0063] Ⅲ. The above-mentioned homogenate was adjusted to pH 7 with 0.5mol / L sodium hydroxide solution, and flavor protease and enzyme activator were added. The mass ratio of the homogenate, flavor...

Embodiment 2

[0067] A method for preparing uric acid-reducing marine fish oligopeptides, comprising the following steps:

[0068] Ⅰ. Remove the skin and bones of the marine fish and take the fish meat, wash the fish meat with 2°C cold water for 3 times, the mass ratio of cold water to fish meat for each washing is 2:1, let it stand for 4 minutes after each washing, and drain the water, Get pre-treated fish meat;

[0069] Ⅱ. Grinding the above-mentioned pretreated fish with a meat grinder, the production capacity of the meat grinder is 120kg / h, and the power is 0.55kw to obtain minced fish with a diameter of 8mm, according to the mass-volume ratio of 1:4 (g / mL) Add water to the obtained minced fish meat, place it in a homogenizer at 30°C and 1500r / min and stir for 30min to obtain a homogenate;

[0070] Ⅲ. The above-mentioned homogenate was adjusted to pH 7 with 0.5mol / L sodium hydroxide solution, and flavor protease and enzyme activator were added. The mass ratio of the homogenate, flavor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com