A kind of surface chemically modified lithium battery cathode material and its application

A technology of positive electrode material and surface chemistry, applied in the field of surface modification of electrode materials for lithium batteries, can solve the problems of unfriendly environment, low electronic and ionic conductivity of positive electrode materials, performance degradation of positive electrode materials, etc., so as to improve cycle stability. , Improve anti-aging ability, improve the effect of rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

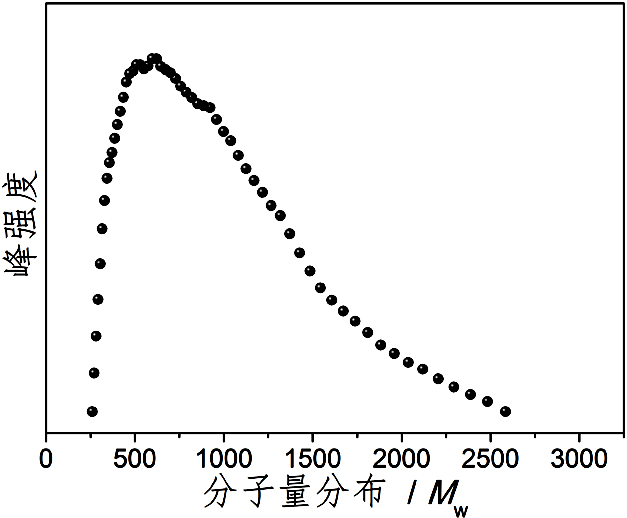

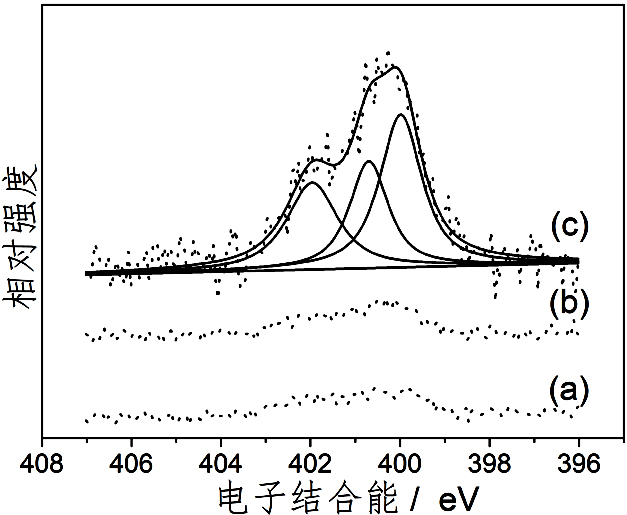

[0090] (1) Preparation of surface-modified LFP / C cathode material

[0091] Add 5 μL of pyrrole to a 50 mL container containing 10 g of LFP / C powder (the size of the powder particles is 0.1-1.5 μm), seal the container, shake the container to mix the LFP / C powder and pyrrole evenly, Aged at room temperature for 7 days. During the aging period, the container was shaken twice a day, and the shaking time was not less than 1 min each time. After the aging period, a surface-modified LFP / C cathode material sample was obtained, which was called cLFPM.

[0092] (2) Aging test

[0093] Open the stopper of the container containing the cLFPM sample to expose the cLFPM sample to the ambient air. In order to fully contact the sample with the ambient air, the container is closed and shaken 3 times a day, and the shaking time is not less than 1 min each time. plug to re-expose the sample to ambient air. The aging time lasted for 2 months, the ambient temperature varied from 15‒38 °C, and th...

Embodiment 2

[0100] (1) Preparation of surface-modified LFP / C powder

[0101] Add 20 μL of pyrrole to a 50mL container containing 10 g of LFP / C powder (the particle size of the powder is 0.1-1.5 μm), seal the container, shake the container to mix the LFP / C powder and pyrrole evenly, and store at room temperature. Under-ripening for 30 days. During the aging period, the container was shaken twice a day, and the shaking time was not less than 1 min each time. After the aging period, a surface chemically modified LFP / C cathode material sample was obtained, which was called cLFPM.

[0102] (2) Aging test

[0103] Open the stopper of the container containing the cLFPM sample to expose the cLFPM sample to the ambient air. In order to fully contact the sample with the ambient air, the container is closed and shaken 3 times a day, and the shaking time is not less than 1 min each time. plug to re-expose the sample to ambient air. The aging time lasted for 4 months, the ambient temperature varied...

Embodiment 3

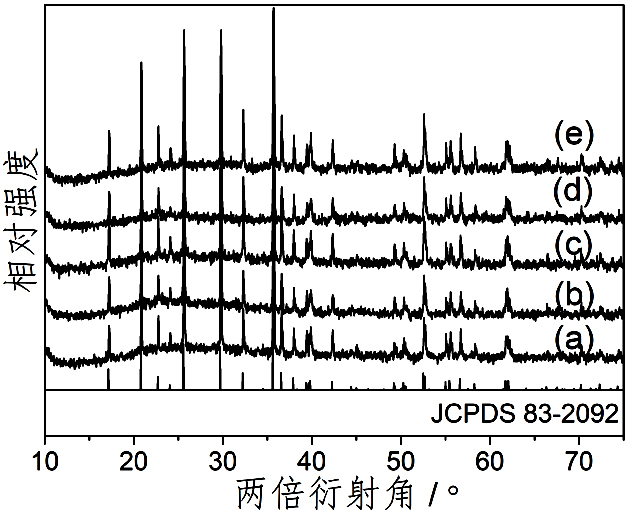

[0124] (1) Preparation of surface-modified LMO cathode materials

[0125] Add 100 μL of thiophene to a 50 mL container containing 10 g of LMO powder (the particle size of the powder is 0.2–1 μm), seal the container, shake the container to mix the LMO powder and thiophene evenly, and mature at room temperature for 30 sky. During the aging period, the container was shaken twice a day, and the shaking time was not less than 5 minutes each time. After the aging period, a surface-modified LMO cathode material sample was obtained, which was called LMOM.

[0126] (2) Aging test

[0127] Open the stopper of the container containing the LMOM sample to expose the LMOM sample to the ambient air. In order to fully contact the sample with the ambient air, the container is closed and shaken 3 times a day, and the shaking time is not less than 1 min each time. plug to re-expose the sample to ambient air. The aging time lasted for 2 months, the ambient temperature varied from 5‒38 °C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com