Visible light responsive g-C3N4/PDI photocatalyst, and preparation method and application thereof

A photocatalyst, g-c3n4 technology, applied in the field of photocatalytic materials, can solve the problems of low catalytic efficiency and lack of effective treatment technology, and achieve the effect of simple preparation method, low price and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a visible light responsive g-C 3 N 4 / PDI photocatalyst preparation method, g-C 3 N 4 / PDI is abbreviated as gCP in the accompanying drawings of the description of the invention; it includes the following steps:

[0034] (1) Preparation of precursor melem: melamine is fired at 400°C to 520°C, preferably at 400°C to 500°C, more preferably at 425°C for 2 to 5 hours, and then washed with water to remove impurities to obtain melem; melem Here it is g-C with a low degree of polymerization fired at a temperature of 400°C to 520°C 3 N 4 .

[0035] (2) Mix the melem obtained in step (1) with PMDA according to the mass ratio of 1:(1~5), under a non-oxygen atmosphere at 300°C~350°C, preferably 310°C~330°C, more preferably 325°C Composite for 200min to 300min, after washing and drying, powdered g-C can be obtained 3 N 4 / PDI photocatalyst. The non-oxygen atmosphere is nitrogen or rare gas, preferably nitrogen.

[0036] The visible light-responsive g...

Embodiment 1

[0042] (1) Preparation of precursor

[0043] Put 3g of melamine in a muffle furnace and burn it at high temperature for 4 hours to polymerize the melamine at high temperature to form melem, a semiconductor material with a wide band gap, and then wash and dry to remove impurities in the system;

[0044] (2) Preparation of g-C 3 N 4 / PDI composite material

[0045] Mix and grind the material obtained in (1) with 1.2g PMDA, put it into a tube furnace, and carry out compounding under nitrogen gas at 325°C, then wash the compounded material for 3 times, and dry it to obtain g-C 3 N 4 / PDI photocatalyst.

[0046] Carry out result analysis according to the catalyst prepared in embodiment 1:

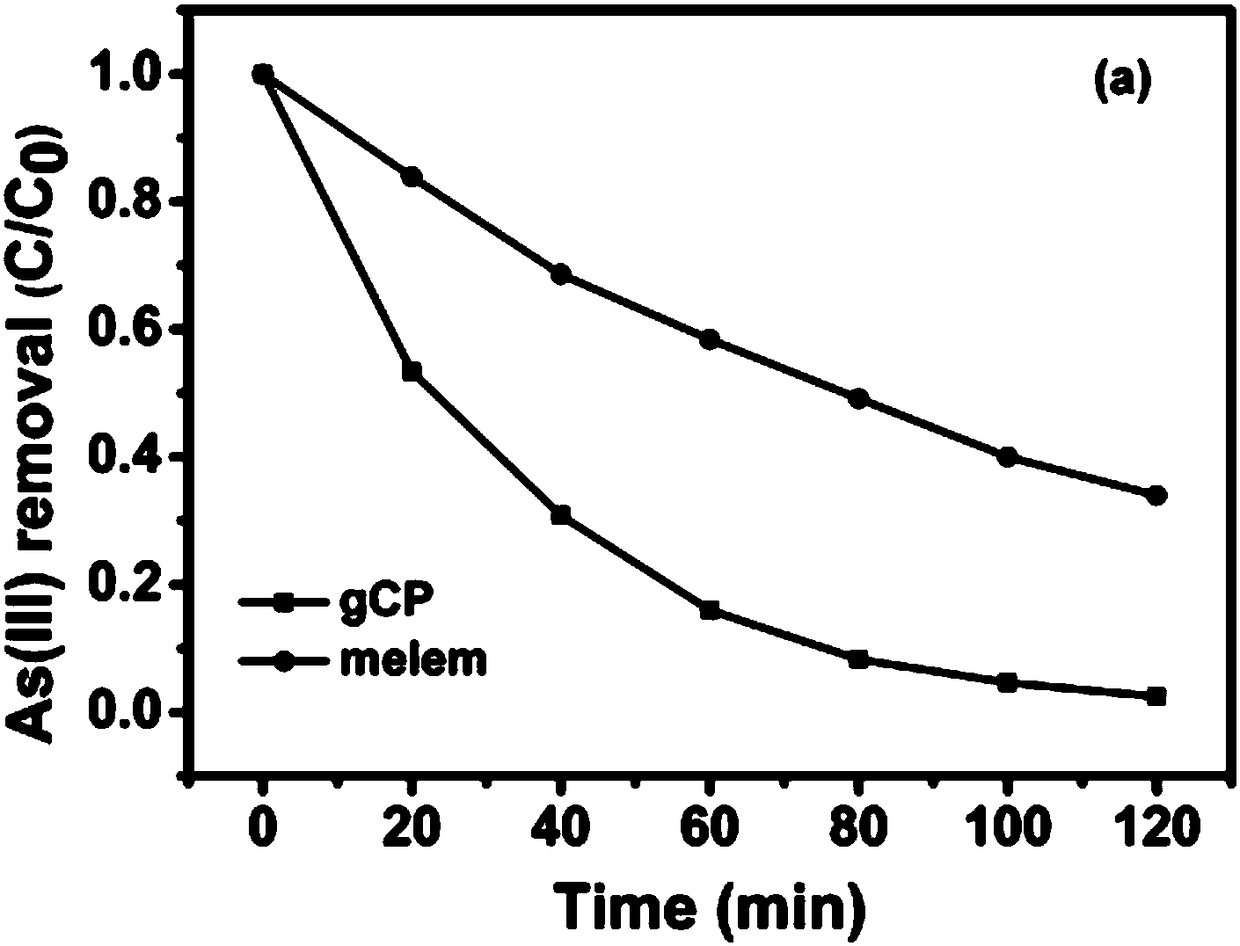

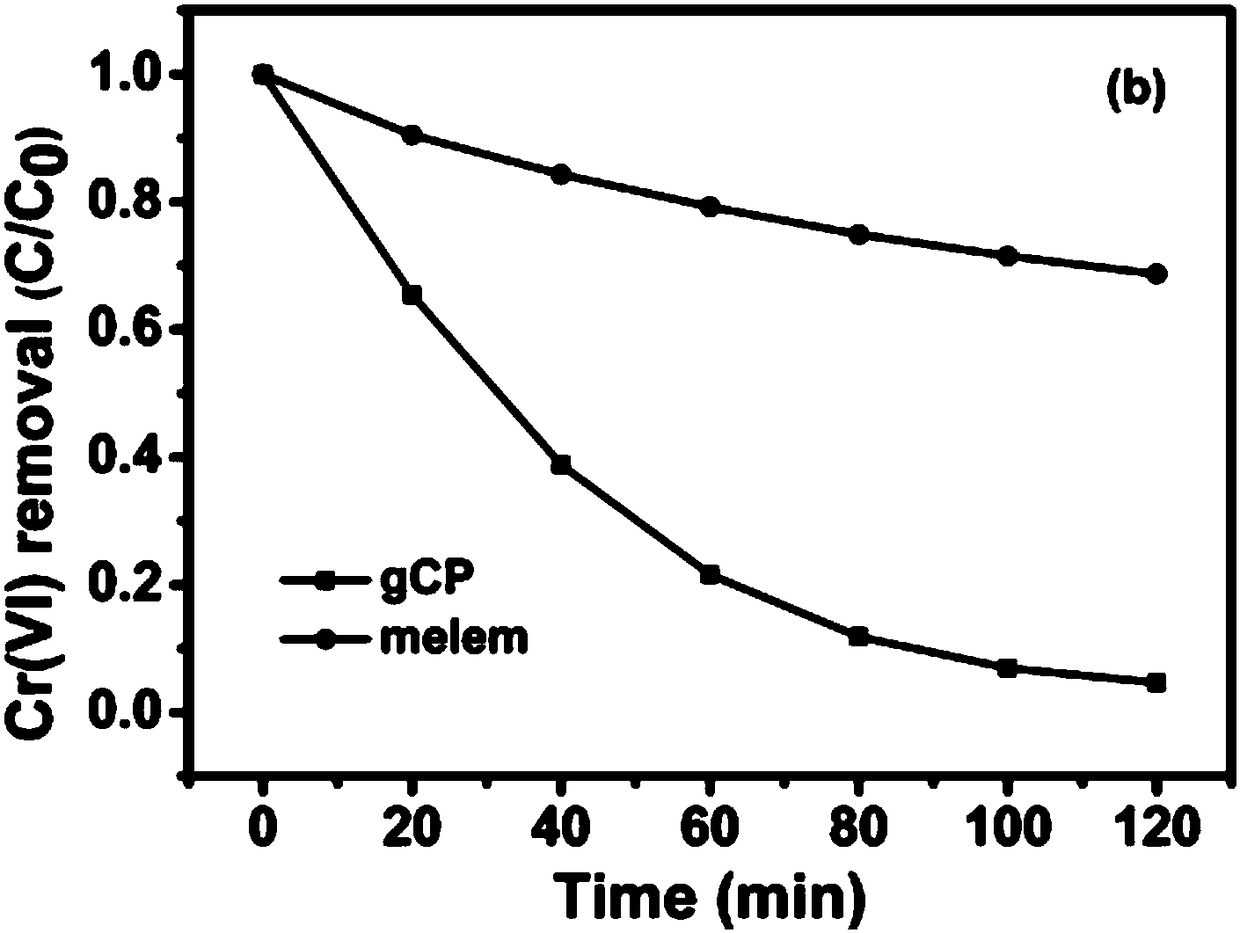

[0047] (1) Oxidation of As(III) and reduction of Cr(VI) under visible light

[0048] g-C 3 N 4 / PDI visible light catalytic activity test: with NaAsO 2 As a source of As(III), K 2 Cr 2 o 7 As a Cr(VI) source, under the irradiation of a 300W xenon lamp (filtering light below 420nm), t...

Embodiment 2

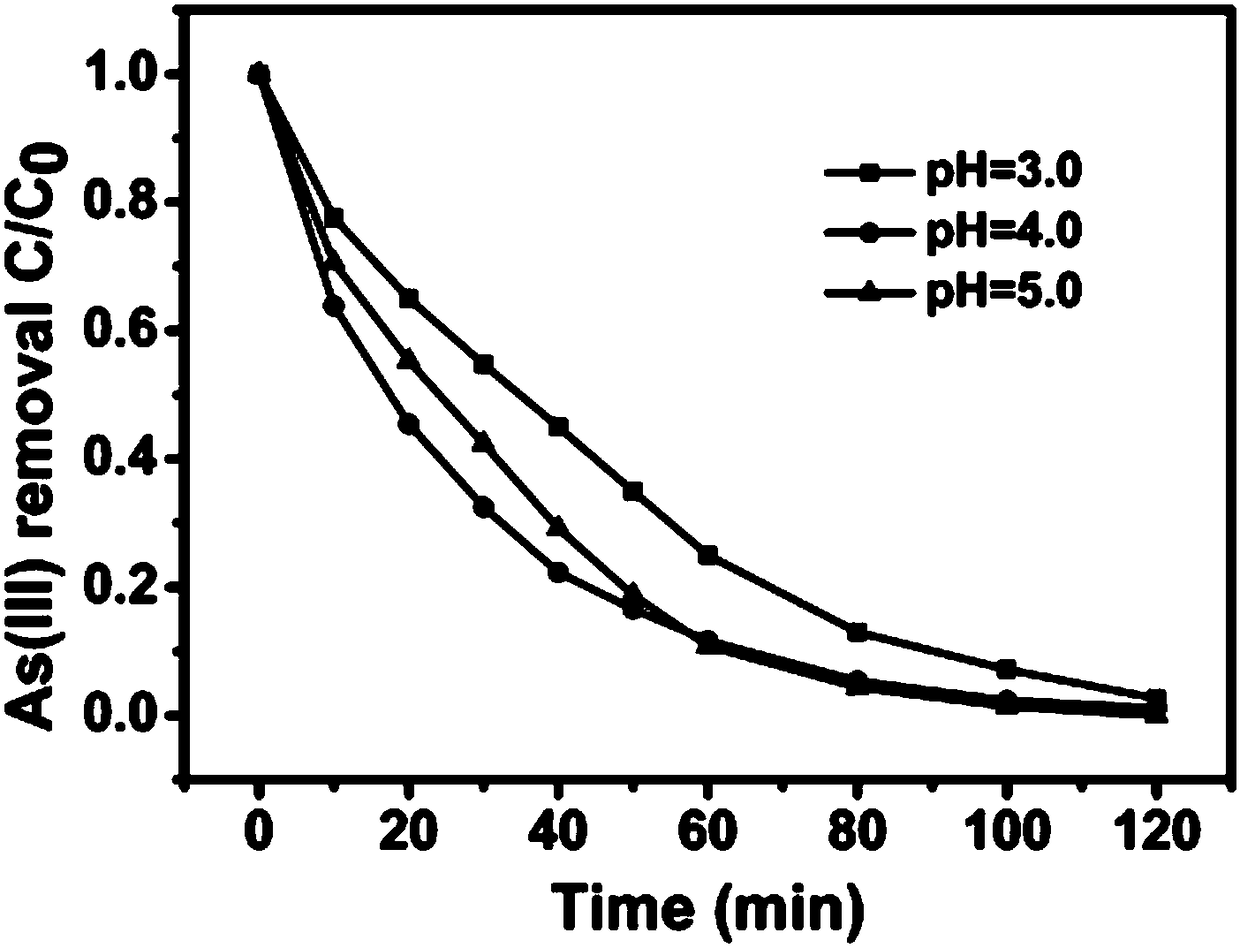

[0068] Figure 7 It is the graph showing the quenching experiment results of As(III) oxidation and Cr(VI) reduction under visible light. Among them, benzoquinone (BQ) is a superoxide radical quencher, ethylenediaminetetraacetic acid (EDTA) is a hole quencher, tert-butanol (TBA) is a hydroxyl radical quencher, and there is no quencher (No scavenger) as a control. By quenching these active substances, it can be seen that the active substances that oxidize As(III) include superoxide radicals, holes and hydroxyl radicals. The initial concentrations of As(III) and Cr(VI) were both 100 μmol / L, the solution volume was 50 mL, the catalyst concentration was 1.0 mg / L, and the pH of the solution was adjusted to 4.0. Before the experiment, it was adsorbed in the dark for 30 minutes, and after the adsorption equilibrium was reached, it was illuminated. The concentration of As(III) was detected by liquid chromatography-fluorescence spectrometer, and the concentration of Cr(VI) was detecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com