Edible composite cling film, and preparation method and application thereof

A composite fresh-keeping and edible technology, applied in flexible covering, transportation and packaging, coating and other directions, can solve the problems of limiting the application of Curdlan related film products, low tensile strength, low elongation performance, etc. Time reduction, high antibacterial and antioxidant activity, effect of strengthening membrane mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

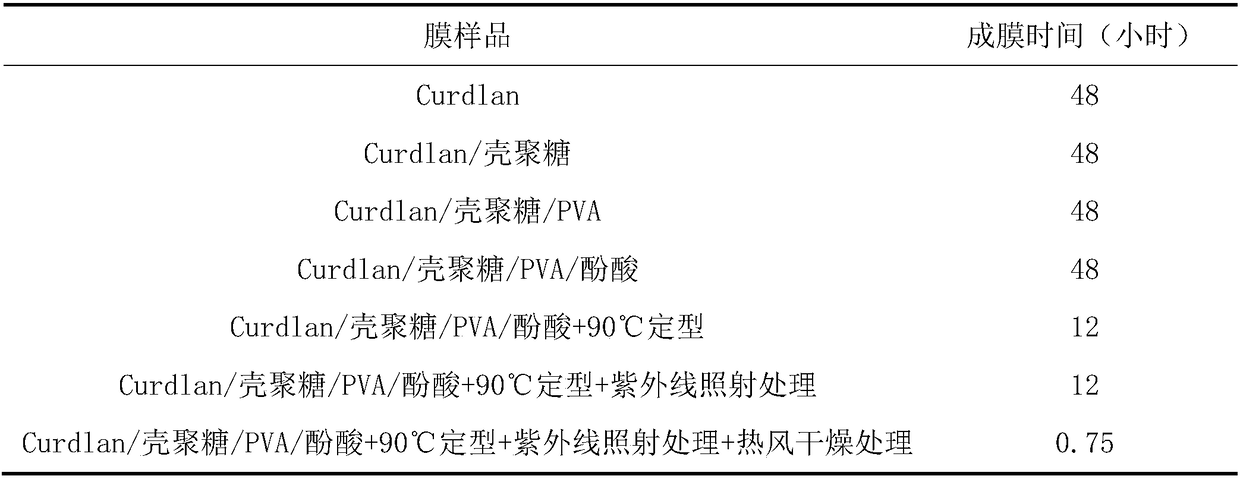

[0045] Example 1: Preparation process of edible composite plastic wrap with different components, and film-making time comparison

[0046] (1) Preparation of Curdlan component film

[0047] ① Weigh 12g of Curdlan powder, dissolve it in 100mL of pure water, and after Curdlan is fully swollen, prepare a suspension under the action of a high-speed shear;

[0048] ②Curdlan suspension and pure water are blended according to the ratio (volume ratio) of 1:1, and the total volume of the blend is 100mL.

[0049] ③Add 2.5g of glycerin, and adjust the pH to 4 with 1mol / L lactic acid solution to obtain a film-forming solution;

[0050] ④ After ultrasonic degassing of the film-forming solution, pour 50ml into a 18cm*18cm polytetrafluoroethylene plate, and dry it naturally to obtain a film.

[0051] (2) Preparation of Curdlan / chitosan component film

[0052] ① Weigh 12g of Curdlan powder, dissolve it in 100mL of pure water, and after Curdlan is fully swollen, prepare a suspension under t...

Embodiment 2

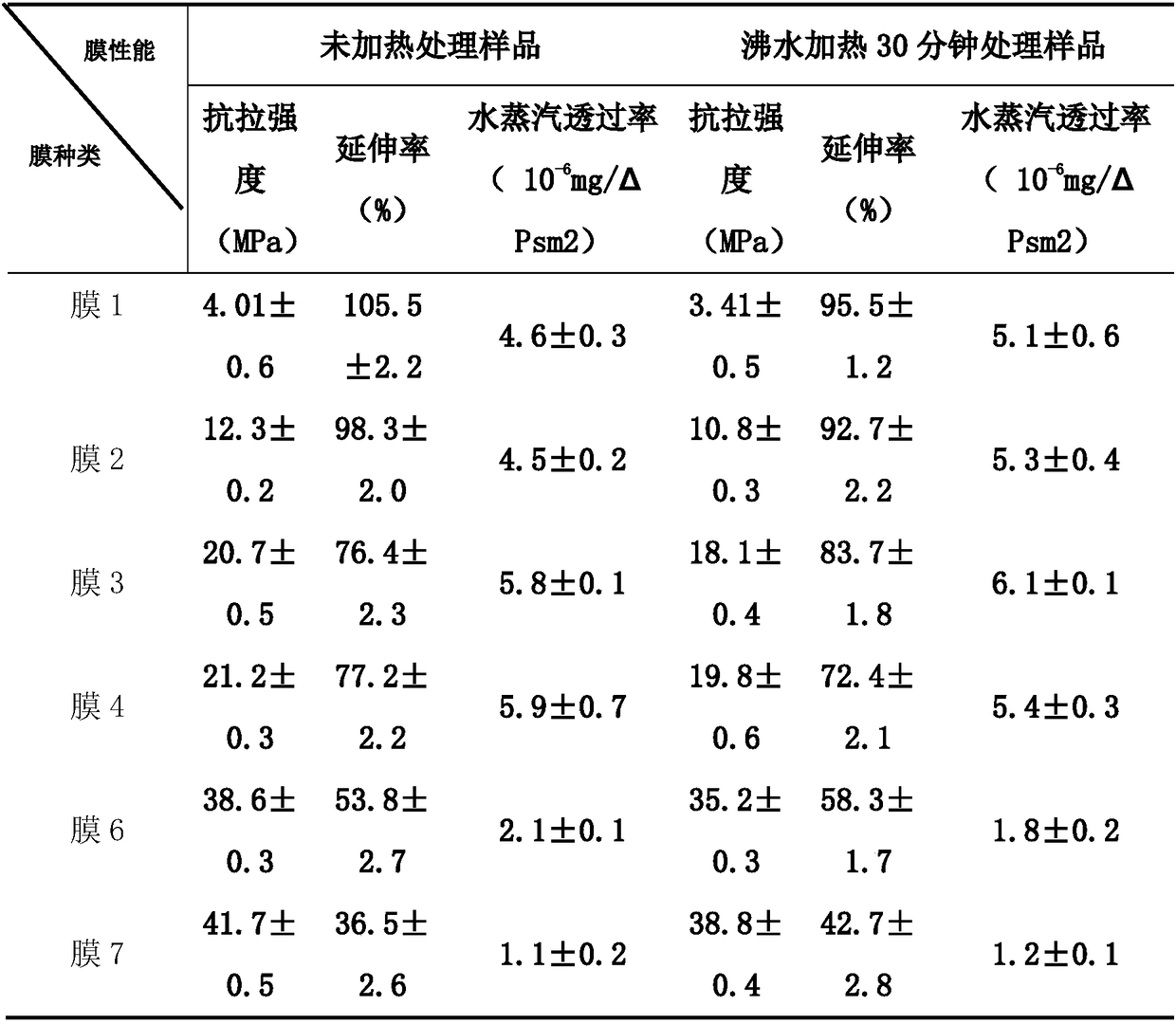

[0102] Embodiment 2: the performance measurement of edible composite plastic wrap

[0103] (1) Mechanical properties

[0104] The film was cut into strips of 8cm*2cm, and fixed on a physical property analyzer for measurement. Set the initial distance between the two fixtures of the physical property meter to 80mm, and the speed to 0.8mm / sec. After the measurement, record the force (g) at the instant the film breaks and the distance L between the two clamps when the film breaks. For each sample, five parallel samples were taken for determination.

[0105] Tensile strength TS (g) is calculated according to the following formula:

[0106] TS=Fm / d*W

[0107] Where: TS—tensile strength, (MPa);

[0108] Fm—the maximum tension that the sample bears when it breaks, (N);

[0109] d—film thickness, (m);

[0110] W—film width, (m).

[0111] The elongation at break E (%) is calculated according to the following formula:

[0112] E=(L 1 - L 0 ) / L 0

[0113] In the formula: E—the...

Embodiment 3

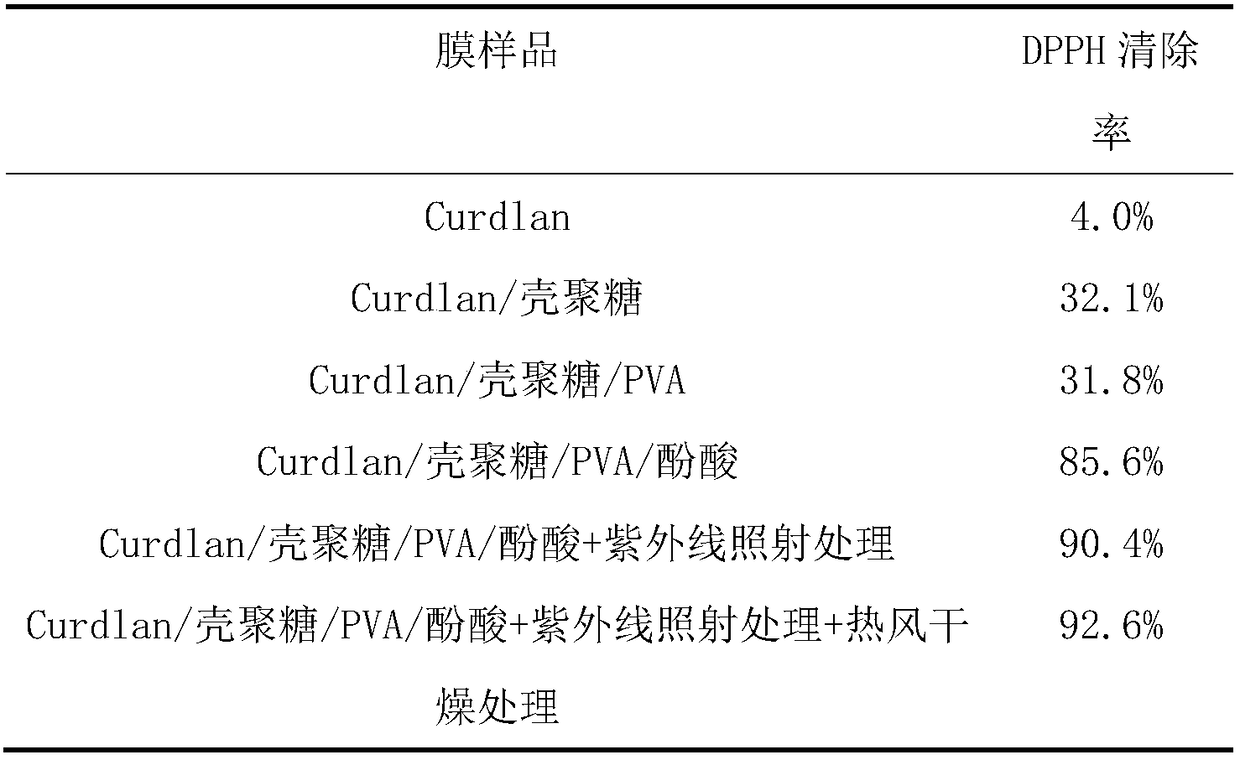

[0125] Embodiment 3: the antioxidant performance of edible composite plastic wrap

[0126] The antioxidant capacity of edible composite plastic wrap was expressed by measuring the scavenging capacity of DPPH. Cut the composite membrane into 20mm×20mm and put it into a beaker, add 100mL of distilled water, and stir on a magnetic stirrer at a speed of 150r / min and a temperature of 25±0.5°C. Sampling 1mL into a test tube at regular intervals, using 1mL of distilled water as a blank control, adding 4mL of DPPH methanol solution (150umol / L) to mix well, keeping it in the dark for 30min to fully react, and measuring the absorbance at 516nm with a UV spectrophotometer. DPPH free radical scavenging ability is calculated as follows:

[0127] DPPH free radical scavenging ability = (1-A sample )×100% / A control

[0128] A sample is the absorbance value of the sample, A control Absorbance value of the blank.

[0129] The antioxidant capacity of the plastic wrap prepared with differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com