Water-based phase change heat expansion type flame-retardant and fireproof coating for tunnels and preparation method thereof

A kind of fire-proof coating, expansion technology, applied in fire-proof coating, anti-fouling/underwater coating, starch coating, etc., can solve the problems of front car methanol leakage, large construction thickness, poor material flatness, etc., to prevent temperature rise , Avoid the effect of strength decline and short maintenance period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

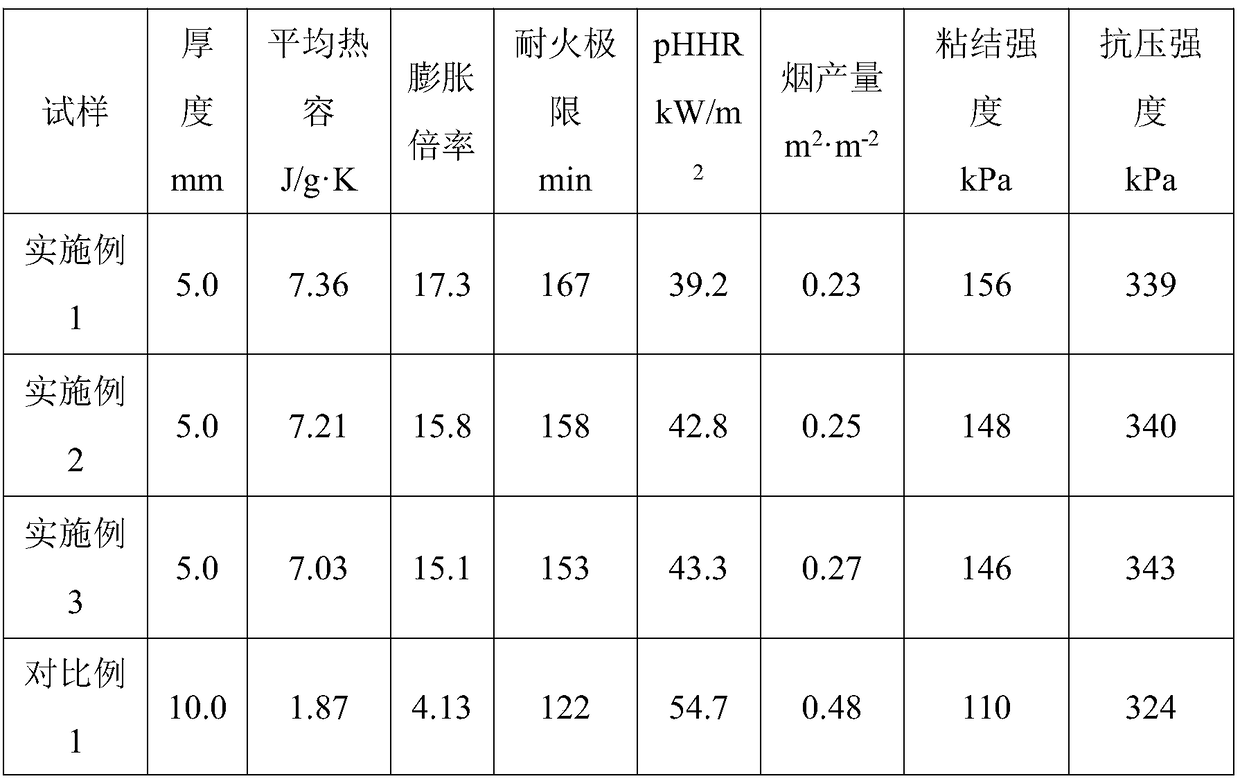

Examples

Embodiment 1

[0047] A water-based phase change endothermic expansion type tunnel flame retardant fireproof coating of the present invention, its preparation method comprises the following steps:

[0048] (1) Heat 8.0kg of expanded perlite in the reactor to 80°C, and simultaneously vacuumize to 40kPa, keep warm and vacuumize for 20min, then add 20kg of mannitol and 10kg of galactose melted under the protection of nitrogen, and keep warm for 80°C under the protection of nitrogen. React at ℃ for 60 minutes, cool the product to room temperature, add 200g of hydroxy silicone oil, and grind it in a planetary ball mill for 2.0 hours to obtain expanded perlite loaded mannitol-galactose;

[0049] (2) Add 12kg of melamine and 2.0L of 0.5mol / L NaOH solution into the reactor, stir evenly, slowly add 8.0L of 37% formaldehyde under stirring, heat up to 50°C for the first stirring and reflux reaction for 120min, Obtain melamine formaldehyde prepolymer; 40kg lignin is added in the reaction kettle, add 11k...

Embodiment 2

[0054] A water-based phase change endothermic expansion type tunnel flame retardant fireproof coating of the present invention, its preparation method comprises the following steps:

[0055] (1) Heat 8.0kg of expanded perlite in the reactor to 80°C, and simultaneously vacuumize to 40kPa, keep warm and vacuumize for 20min, then add 20kg of mannitol and 10kg of galactose melted under the protection of nitrogen, and keep warm for 80°C under the protection of nitrogen. React at ℃ for 60 minutes, cool the product to room temperature, add 200g of hydroxy silicone oil, and grind it in a planetary ball mill for 2.0 hours to obtain expanded perlite loaded mannitol-galactose;

[0056] (2) Add 12kg of melamine and 2.0L of 0.5mol / L NaOH solution into the reactor, stir evenly, slowly add 8.0L of 37% formaldehyde under stirring, heat up to 50°C for the first stirring and reflux reaction for 120min, Obtain melamine formaldehyde prepolymer; 40kg lignin is added in the reaction kettle, add 11k...

Embodiment 3

[0061] A water-based phase change endothermic expansion type tunnel flame retardant fireproof coating of the present invention, its preparation method comprises the following steps:

[0062] (1) Heat 8.0kg of expanded perlite in the reactor to 80°C, and simultaneously vacuumize to 40kPa, keep warm and vacuumize for 20min, then add 20kg of mannitol and 10kg of galactose melted under the protection of nitrogen, and keep warm for 80°C under the protection of nitrogen. React at ℃ for 60 minutes, cool the product to room temperature, add 200g of hydroxy silicone oil, and grind it in a planetary ball mill for 2.0 hours to obtain expanded perlite loaded mannitol-galactose;

[0063] (2) Add 12kg of melamine and 2.0L of 0.5mol / L NaOH solution into the reactor, stir evenly, slowly add 8.0L of 37% formaldehyde under stirring, heat up to 50°C and stir for the first reflux reaction for 120min, Obtain melamine formaldehyde prepolymer; 40kg lignin is added in the reaction kettle, add 11kg 85...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com