Environment-friendly water-based bi-component nylon screen printing ink and use method thereof

A two-component, nylon filament technology, applied in the field of ink, can solve the problems of water resistance, poor color fastness to scratches, poor ink covering ability, poor ink abrasion resistance, etc., and achieves strong covering ability and good color fastness. , The effect of excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

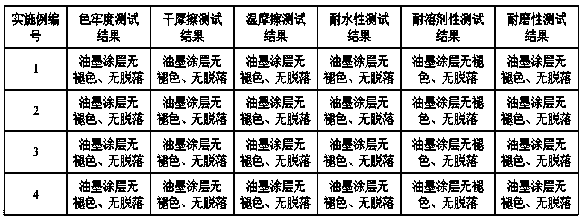

Examples

Embodiment 1

[0035] Preparation of component A: 13% modified water-based acrylic emulsion, 32% modified water-based polyurethane emulsion, 25% water-based titanium dioxide, 6% talcum powder, 2% sodium lauryl sulfate, 2% Add polyamide wax, 3% ethanol, 10% deionized water, 3% iron oxide yellow, and 4% additives into the agitator, control the stirring speed to 1200r / min, and transfer to three-roller grinding after stirring evenly Grind twice in the machine to obtain Component A.

[0036] The preparation method of described modified water-based acrylic acid emulsion: the mass percent is respectively 52% acrylic resin, 28% varnish, 12% polytetrafluoroethylene, 8% dibasic acid ester (from dimethyl succinate ester, dimethyl glutarate, and dimethyl adipate are mixed according to the mass percentage of 1:0.8:1.1) into the stirrer, the stirring speed is controlled at 500r / min, and after stirring at 25°C for 1h, the Adjust the stirring speed to 1200r / min, add deionized water, and stir evenly to prep...

Embodiment 2

[0041] Preparation of component A: 10% modified water-based acrylic emulsion, 30% modified water-based polyurethane emulsion, 28% water-based titanium dioxide, 5% talcum powder, 1% sodium lauryl sulfate, 2% Add polyamide wax, 4% ethanol, 12% deionized water, 5% carbon black, and 3% additives into the agitator, control the stirring speed to 1200r / min, and transfer to the three-roller grinder after stirring Internal milling twice yielded Component A.

[0042] The preparation method of described modified water-based acrylic acid emulsion: the mass percent is respectively 57% acrylic resin, 20% varnish, 15% polytetrafluoroethylene, 8% dibasic acid ester (from dimethyl succinate ester, dimethyl glutarate, and dimethyl adipate are mixed according to the mass percentage of 1:0.8:1.1) into the stirrer, the stirring speed is controlled at 500r / min, and after stirring at 25°C for 1h, the Adjust the stirring speed to 1200r / min, add deionized water, and stir evenly to prepare the modifie...

Embodiment 3

[0047] Preparation of component A: 11% modified water-based acrylic emulsion, 30% modified water-based polyurethane emulsion, 25% water-based titanium dioxide, 6% talcum powder, 2% sodium lauryl sulfate, 4% Add polyamide wax, 3% ethanol, 12% deionized water, 5% brown iron oxide, and 2% additives into the agitator, control the stirring speed to 1200r / min, and transfer to three-roller grinding after stirring evenly Grind twice in the machine to obtain Component A.

[0048] The preparation method of described modified water-based acrylic acid emulsion: the mass percent is respectively 62% acrylic resin, 25% varnish, 8% polytetrafluoroethylene, 5% dibasic acid ester (from dimethyl succinate ester, dimethyl glutarate, and dimethyl adipate are mixed according to the mass percentage of 1:0.8:1.1) into the stirrer, the stirring speed is controlled at 500r / min, and after stirring at 25°C for 1h, the Adjust the stirring speed to 1200r / min, add deionized water, and stir evenly to prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com