Preparation method of fermented bean curd powder

A technology of fermented bean curd and bacterial strains, which is applied in food science, food preservation, food ingredients as taste improvers, etc., can solve the problems of long preparation cycle and complicated process of fermented bean curd powder, and achieve the advantages of short preparation cycle, repeated fermentation, and enhanced flavor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

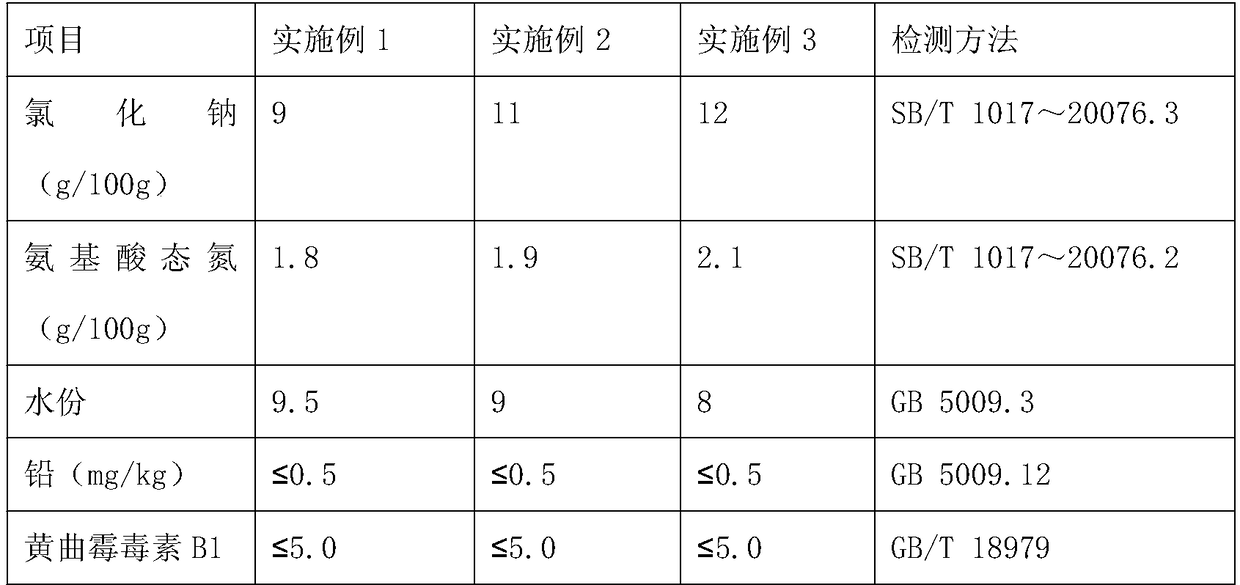

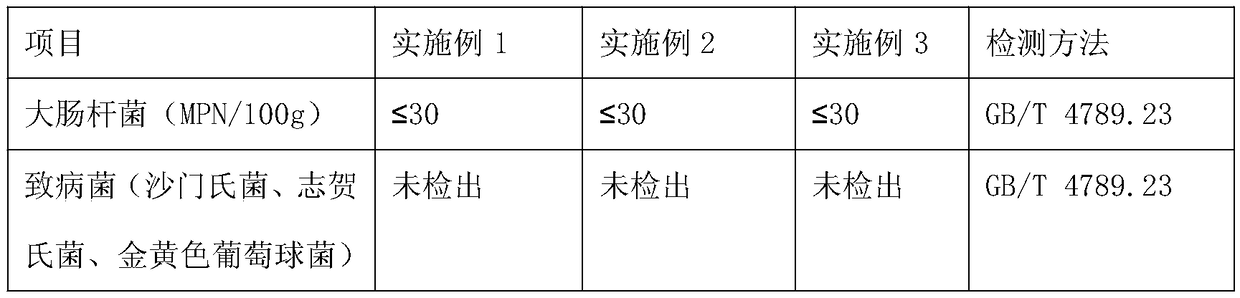

Embodiment 1

[0027] A) (1) disinfection, aseptic treatment of the production environment;

[0028] (2) billet making, adopt acid water method, automation equipment to make bean billet;

[0029] (3) For pre-fermentation, spray the enlarged cultured Yazhi radioactive Mucor As3.2778 strain on the fermentation plate, place the bean base cooled to room temperature on the fermentation plate, and spray the expanded cultured Yazhi evenly on the bean base. Mucor radioactive As3.2778 strain, the amount of strain used is 0.2wt% of the mass of bean dregs; fermented at normal pressure and 15°C for 3 days to obtain mold dregs;

[0030] B) (1) add the salt of 3wt% of the quality of mold and 0.5wt% of the quality of mold, 50 ° of white wine and the aroma yeast of 1.5wt% of the quality of inoculated bean dough to carry out post-fermentation in the mold base, and at the same time Add seasoning and ferment for 4 days. The fermentation conditions are as follows: the temperature is 25°C, the humidity is 80%, ...

Embodiment 2

[0035] A) (1) disinfection, aseptic treatment of the production environment;

[0036] (2) billet making, adopt acid water method, automation equipment to make bean billet;

[0037] (3) For pre-fermentation, spray the enlarged cultured Yazhi radioactive Mucor As3.2778 strain on the fermentation plate, place the bean base cooled to room temperature on the fermentation plate, and spray the expanded cultured Yazhi evenly on the bean base. Mucor radioactive As3.2778 strain, the amount of strain used is 0.3wt% of the mass of bean dregs; fermented at normal pressure and 18°C for 4 days to obtain mold dregs;

[0038] B) (1) add the 4wt% salt of mold quality and the 0.8wt% of mold quality, the white wine of 53 ° and inoculate 1.8wt% of bean dough quality in mold base to carry out post-fermentation, simultaneously Add seasoning and ferment for 4.5 days. The fermentation conditions are as follows: temperature is 30°C, humidity is 85%, and mature fermented bean curd rich in aroma and f...

Embodiment 3

[0043] A) (1) disinfection, aseptic treatment of the production environment;

[0044] (2) billet making, adopt acid water method, automation equipment to make bean billet;

[0045] (3) For pre-fermentation, spray the enlarged cultured Yazhi radioactive Mucor As3.2778 strain on the fermentation plate, place the bean base cooled to room temperature on the fermentation plate, and spray the expanded cultured Yazhi evenly on the bean base. Mucor radioactive As3.2778 strain, the amount of strain used is 0.4wt% of the mass of bean dregs; fermented at normal pressure and 20°C for 5 days to obtain mold dregs;

[0046] B) (1) Add 5wt% of salt and 1.2wt% of mold quality, 60° white wine and 2wt% of inoculated bean dough quality into mold base to carry out post-fermentation, and add The seasoning is fermented for 5 days, and the fermentation conditions are as follows: the temperature is 35°C, and the humidity is 90%, to obtain mature fermented bean curd rich in aroma and flavor substances...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com