Method for removing fluorine and chloride ions from high-concentration industrial waste acid

An industrial waste acid and high-concentration technology, which is applied in chemical instruments and methods, nitric acid, sulfur trioxide/sulfuric acid, etc., can solve the problems of large environmental pollution, complicated and dangerous operation, and the recovery and reuse of waste acid that does not involve chloride ions at the same time. , to achieve the effect of low equipment investment, simple process flow and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

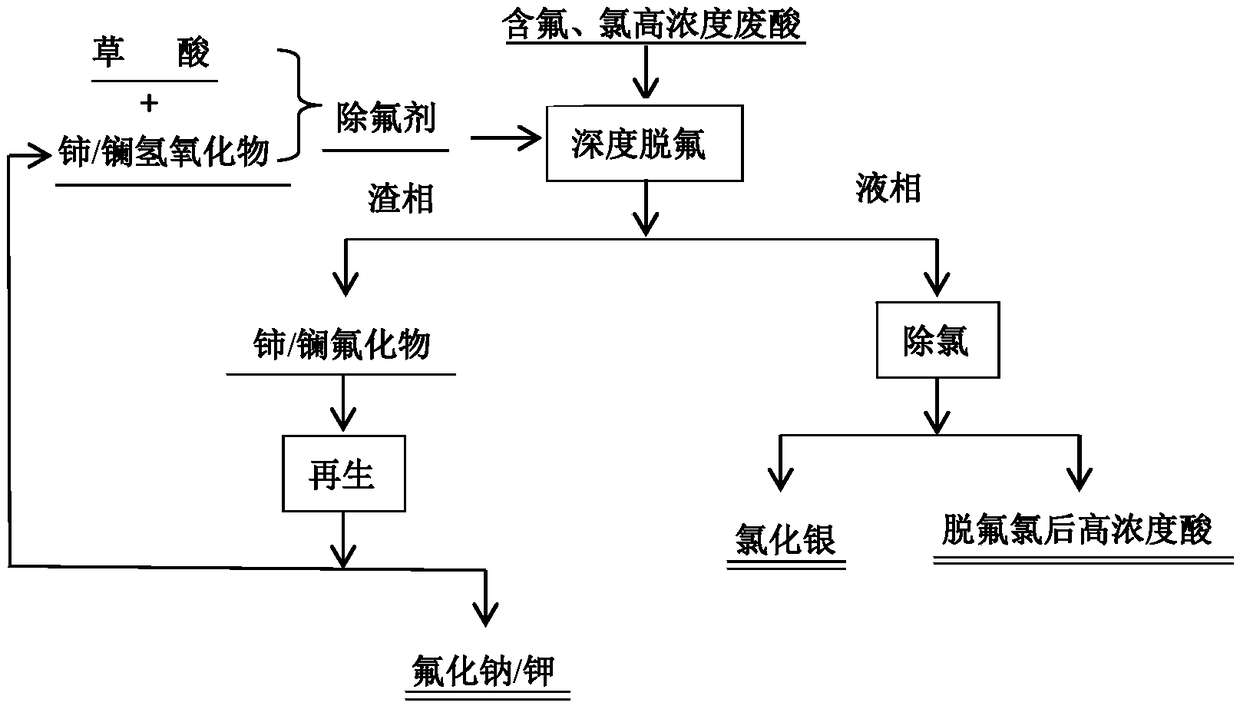

[0034] A method for removing fluorine and chloride ions from high-concentration industrial waste acid,

[0035] Including: first take 500ml of high-concentration industrial waste acid, which contains 50g / L H 2 SO 4 , 200g / L HNO 3 Adding 50ml molar concentration of 4mol / L cerium hydroxide and lanthanum mixed solution (1:10 mixing) and 7ml molar concentration of 1.5mol / L oxalic acid to waste acid is used as defluorination agent to carry out deep defluorination, defluorination reaction 1h, after defluorination is completed, filter and separate to obtain liquid phase and slag phase, the slag phase is a mixture of cerium fluoride and lanthanum fluoride; the mixture of cerium fluoride and lanthanum fluoride is regenerated with 300g / L sodium hydroxide solution to obtain fluoride The mixture of sodium chloride, cerium hydroxide and lanthanum hydroxide, the mixture of cerium hydroxide and lanthanum hydroxide is mixed with 7ml of oxalic acid with a molar concentration of 2mol / L to mak...

Embodiment 2

[0037] A method for removing fluorine and chloride ions from high-concentration industrial waste acid,

[0038] Including: first take 500ml of high-concentration industrial waste acid, which contains 150g / L H 2 SO 4 , 200g / L HNO 3 ; Add 20ml molar concentration of 4mol / L cerium hydroxide, lanthanum mixed solution (1:4 mix) and 8.5ml molar concentration of 1.8mol / L oxalic acid as defluorination agent to carry out deep defluorination, defluorination React for 0.5h, after defluorination is completed, filter and separate to obtain liquid phase and slag phase, the slag phase is a mixture of cerium fluoride and lanthanum fluoride; the mixture of cerium fluoride and lanthanum fluoride is regenerated with 50g / L potassium hydroxide solution, Obtain the mixture of potassium fluoride, cerium hydroxide and lanthanum hydroxide, the mixture of cerium hydroxide and lanthanum hydroxide is mixed with 8.5ml of oxalic acid with a molar concentration of 1.8mol / L to make a defluorinating agent a...

Embodiment 3

[0040] A method for removing fluorine and chloride ions from high-concentration industrial waste acid,

[0041] Including: first take 500ml of high-concentration industrial waste acid, which contains 200g / L H 2 SO 4 , 300g / L HNO 3 Adding 40ml molar concentration of 4mol / L cerium hydroxide and lanthanum mixed solution (1:1 mixing) and 9ml molar concentration of 0.5mol / L oxalic acid to waste acid is used as defluorination agent to carry out deep defluorination, defluorination reaction 2.5h, after defluorination is completed, filter and separate to obtain liquid phase and slag phase, the slag phase is a mixture of cerium fluoride and lanthanum fluoride; the mixture of cerium fluoride and lanthanum fluoride is regenerated with 350g / L sodium hydroxide solution to obtain The mixture of sodium fluoride, cerium hydroxide and lanthanum hydroxide, the mixture of cerium hydroxide and lanthanum hydroxide is mixed with 9ml of oxalic acid with a molar concentration of 0.5mol / L to make a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com