Anionic gemini surfactant and preparation method thereof

A gemini surface, anionic technology, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problems of gemini surfactant cost-effectiveness to be improved, and achieve low cost, simple synthesis process, and easy biodegradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

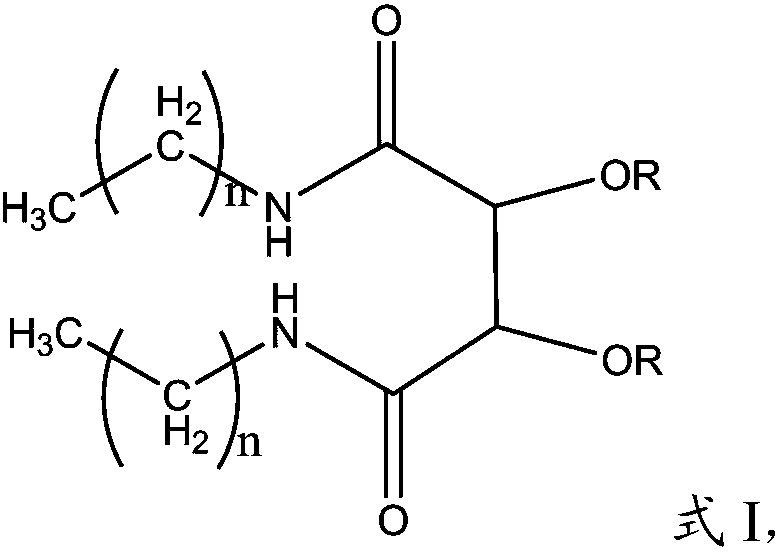

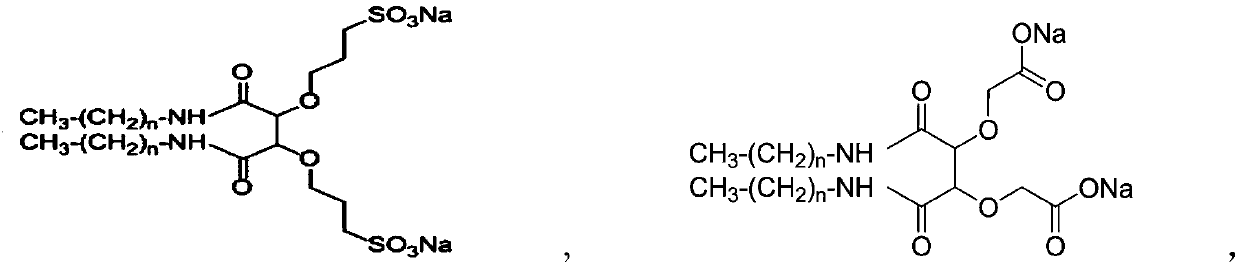

[0032] The present invention provides the preparation method of anionic gemini surfactant described in above-mentioned technical scheme, comprises the following steps:

[0033] (1) tartaric acid, thionyl chloride and solvent are mixed, carry out esterification reaction, obtain tartrate diester;

[0034] (2) mixing the tartrate diester, solvent and fatty amine for amidation reaction to obtain tartrate amide;

[0035] (3) Place the tartaric acid amide in a reactor, add an anionic reagent dropwise in an ice-water bath under a protective atmosphere, react directly or under the action of a catalyst, and then neutralize it with an alkali to obtain an anionic tartrate amide Gemini surfactants.

[0036] The present invention mixes tartaric acid, thionyl chloride and a solvent for esterification to obtain tartrate diester. In the present invention, the tartaric acid is preferably L-tartaric acid. In the present invention, the solvent is preferably ethanol or methanol, more prefera...

Embodiment 1

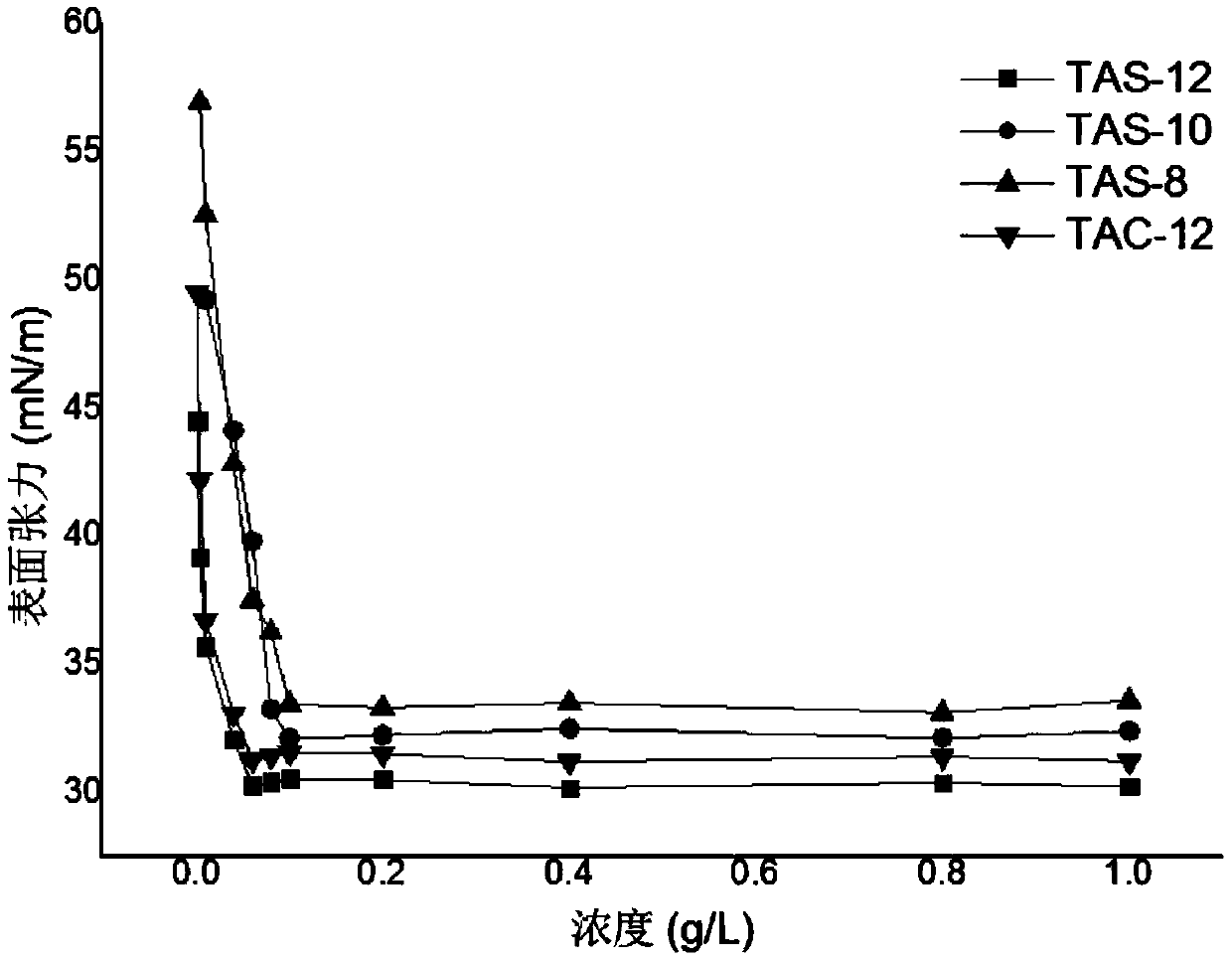

[0070] Mix absolute ethanol (70 mL) and diethyl tartrate (20.6 g, 0.1 mol), add n-octylamine (27.1 g, 0.21 mol) dropwise under stirring, heat the oil bath to reflux, and react for 8 h. After the reaction solution was completely cooled to room temperature, it was washed three times with 150 mL of absolute ethanol to obtain a white solid; then recrystallized with 200 mL of absolute ethanol to obtain needle-like white crystals, which obtained octaamide tartrate with a yield of (31.25 g, 84.0%) .

[0071] The tartrate octaamide (1.86g, 5mmol) and propane sultone (1.83g, 15mmol) were mixed, and 60% sodium hydride (0.6g, 30mmol) and no Water tetrahydrofuran (70mL), in which sodium hydride was added in three times on average, reacted at room temperature for 48h, after the reaction was completed, 10mL of 10% ammonium chloride solution was added to remove excess sodium hydride, tetrahydrofuran was removed by rotary evaporation, and dried in a vacuum oven to constant weight to obtain c...

Embodiment 2

[0076] Anhydrous ethanol (70mL) was mixed with diethyl tartrate (20.6g, 0.1mol), and n-decylamine (33.0g, 0.21mol) was added dropwise under stirring; then the oil bath was heated to reflux, and the reaction was carried out for 8 hours. After the reaction solution was completely cooled to room temperature, it was washed three times with 150 mL of absolute ethanol to obtain a white solid; then recrystallized with 200 mL of absolute ethanol to obtain decanamide tartrate with a yield of (35.57 g, 83.1%).

[0077] The tartrate decanamide (1.86g, 5mmol) and propane sultone (1.83g, 15mmol) were mixed, and in a nitrogen atmosphere, 60% sodium hydride (0.6g, 30mmol) and no Water tetrahydrofuran (70ml), in which sodium hydride was added in three times on average, reacted at room temperature for 48h, after the reaction was completed, 10mL of 10% ammonium chloride solution was added to remove excess sodium hydride, tetrahydrofuran was removed by rotary evaporation, and dried in a vacuum ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com