A kind of preparation method of electronic grade triglycidyl isocyanurate

A technology of triglycidyl isocyanurate, which is applied in the direction of organic chemistry, can solve the problems of high production cost, environmental hazards, and high residual chlorine in products, and achieve the reduction of production cost and energy consumption, the reduction of cost increase, and the improvement of product quality Effect

Active Publication Date: 2020-05-15

HUANGSHAN JINFENG INDAL

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although this method avoids epichlorohydrin hydrolysis and TGIC ring-opening to generate by-products in the cyclization process to a certain extent, catalyst residues still exist, and the cyclization process needs to consume a large amount of methanol and product post-treatment will generate a large amount of sewage. Obviously Higher production costs and serious harm to the environment

[0006] It can be seen that the existing production process for preparing electronic-grade TGIC products, due to the unreasonable use of catalysts, the use of a large amount of methanol for crystallization and the washing of large amounts of water for post-treatment of products, not only leads to high residual chlorine in products, high production costs, but also is very unfavorable to environmental protection.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

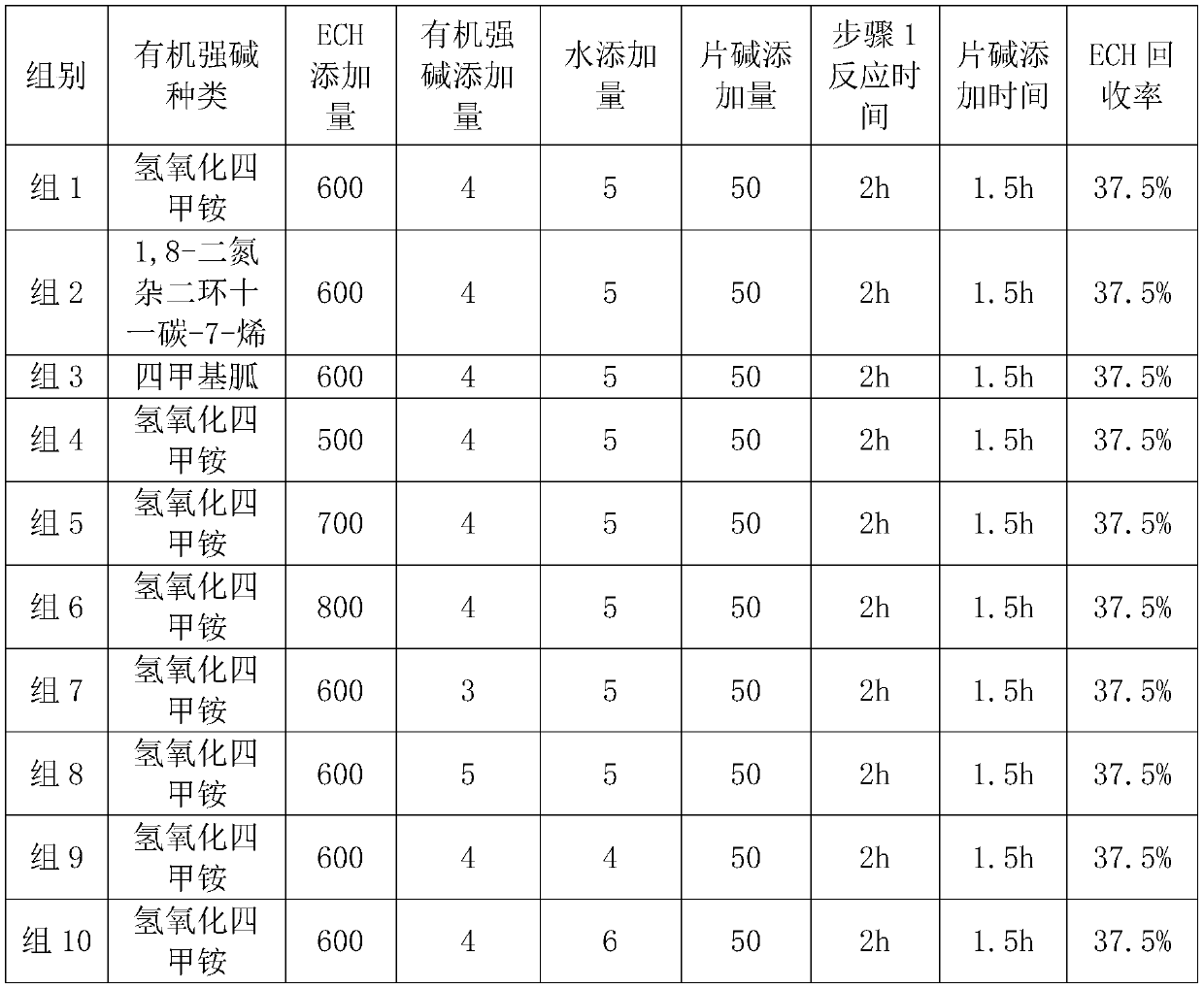

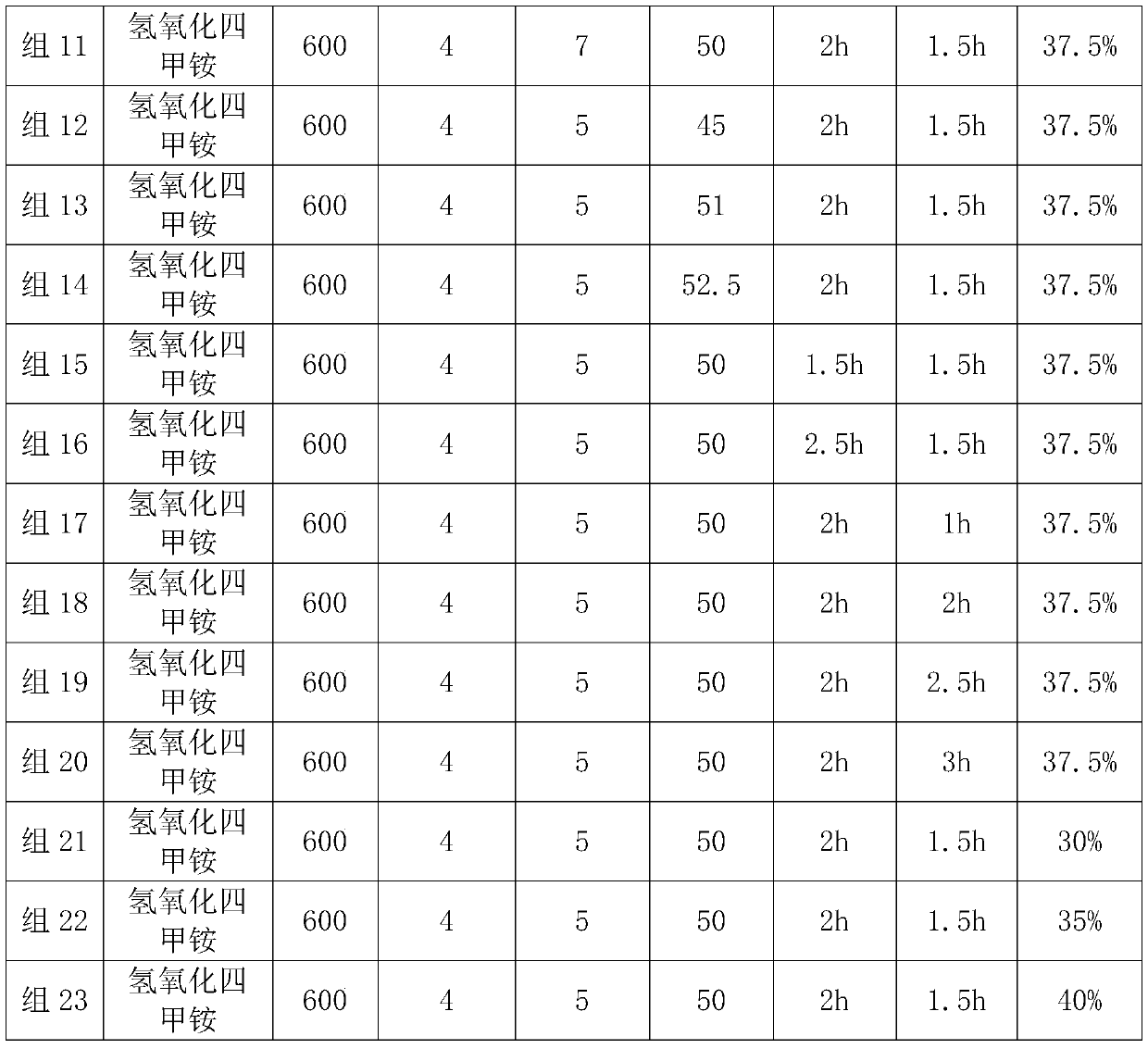

[0040] 1. Prepare 23 groups of TGIC products in equivalent amounts according to the above steps, and the specific parameters of each group are shown in Table 1. Wherein, the added materials are represented by weight ratio.

[0041] The concrete parameter of each embodiment of table 1

[0042]

[0043]

[0044] 2. Comparison of TGIC qualification rate produced by each group

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

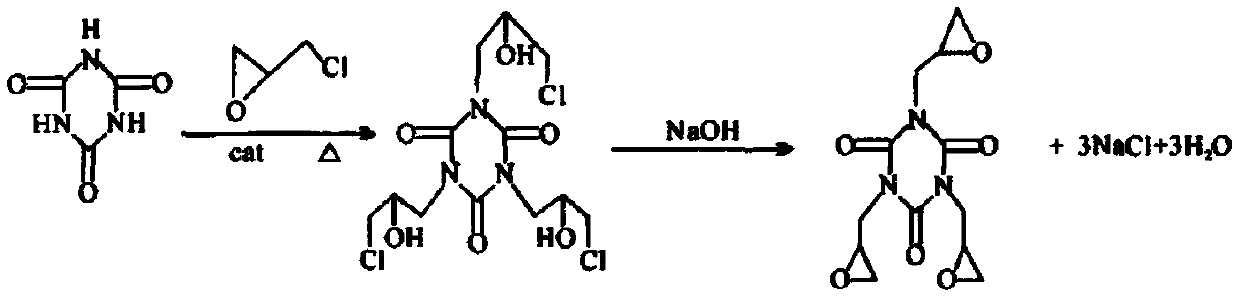

The invention belongs to the technical field of chemical preparations, and particularly relates to a preparation method for electronic-grade triglycidyl isocyanurate. The method specifically comprisesthe following steps: uniformly mixing cyanuric acid, epoxy chloropropane, organic strong base and water, reacting for 1.5 h at 75-80 DEG C; heat-insulating for 1 h at 100 DEG C; in vacuum, 35-40 DEGC, adding sodium hydroxide; vacuum-unloading, removing a solid phase, adding clear water to mother liquor, stewing and removing superstratum saline water; in vacuum, 60-70 DEG C, evaporating a part ofepoxy chloropropane from the substratum mother liquor; placing a distilled material in a crystallization kettle, stirring, at 8-10 DEG C, and removing a liquid phase; decompressing the solid phase, and microwave-drying, to obtain a final product. The catalyst is the organic strong base which does not contain halogen, and the final product has not a halide ion residue. A cyclization process is alkalified in vacuum, so epoxy chloropropane hydrolysis caused by alkaline water and a by-product produced by TGIC cycle opening are avoided. The technical scheme of the preparation method is used, so the product quality is apparently improved, the product cost and the energy consumption are greatly reduced, and the environment is friendly.

Description

technical field [0001] The invention belongs to the technical field of preparation of chemical preparations, and in particular relates to a new method for preparing electronic-grade triglycidyl isocyanurate. Background technique [0002] Triglycidyl isocyanurate (TGIC), chemical name tris(2,3-epoxypropyl)-s-triazine-2,4,6-(1H-3H-5H)-trione, is a A heterocyclic organic compound, because it contains three epoxy groups and a triazine ring structure, has high functionality, reactivity and excellent chemical stability, and is widely used as an excellent curing agent for thermosetting powders It is an irreplaceable curing agent in the coating industry, especially in printed circuit boards (PCB). Due to the stable triazine ring structure in the TGIC molecular structure, the TGIC powder coating has good heat resistance and weather resistance. At the same time, the amide group in the triazine ring makes it easy to crystallize into crystals, which is suitable for large-scale industri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07D405/14

CPCC07D405/14

Inventor 洪昭雷吴锡成王建坤

Owner HUANGSHAN JINFENG INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com