Environment-friendly cross-linked polyvinyl chloride waterproof coiled material and preparation method thereof

A cross-linked polyvinyl chloride and waterproof membrane technology, which is applied in the field of waterproof membranes, can solve problems such as low tensile strength, poor durability, and poor wear resistance, and achieve improved weather resistance, chemical resistance, and heat treatment dimensional change rate Small, to avoid the effect of gel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

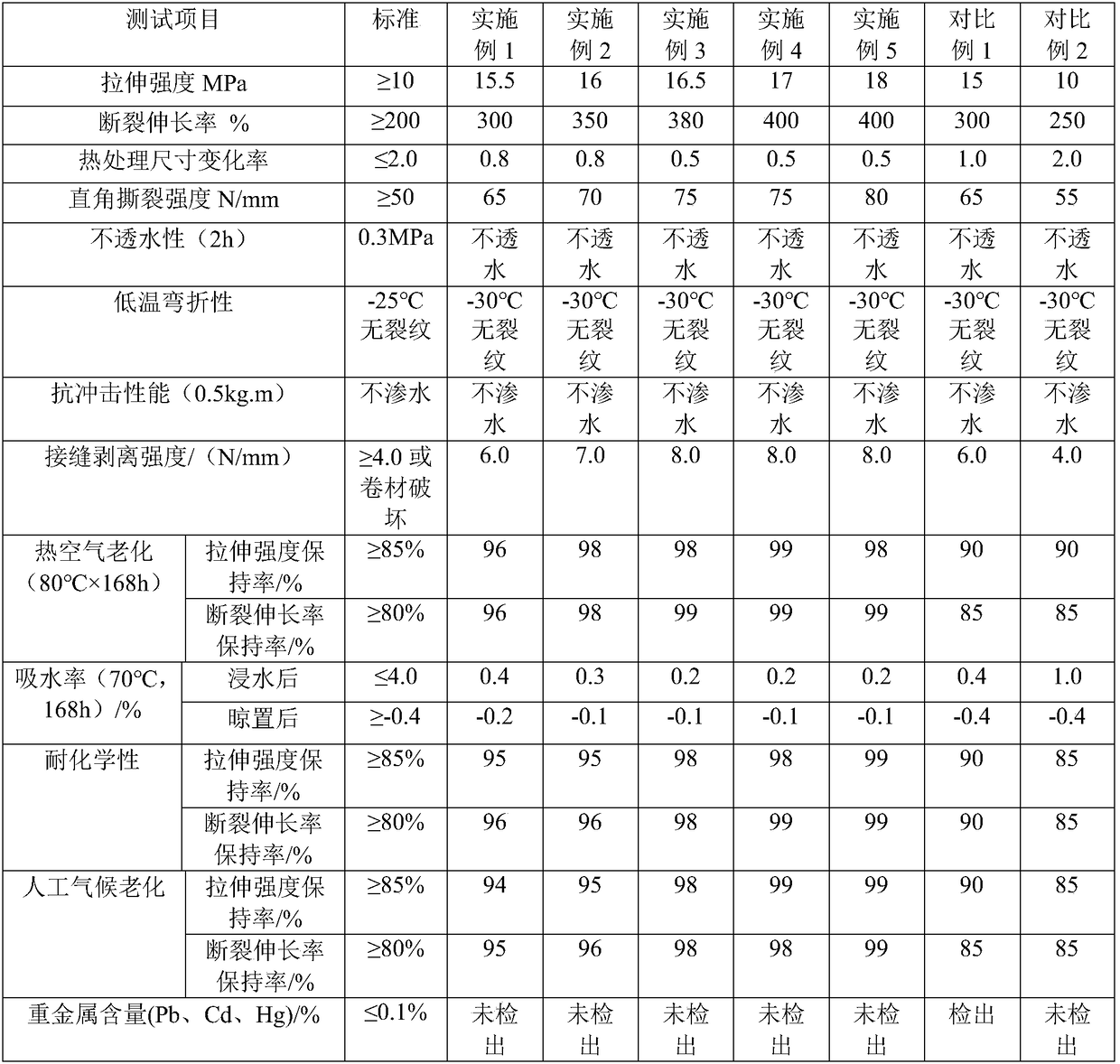

Examples

Embodiment 1

[0050] An environment-friendly cross-linked polyvinyl chloride waterproof membrane, the preparation process of which is as follows:

[0051](1) Kneading: 10 parts of polyvinyl chloride powder (SG-3), 10 parts of ethylene-vinyl acetate (Va=60%), 5 parts of dipropylene glycol dibenzoate (DPGDB), 5 parts of vinyl triethoxy 2 parts of base silane, 1 part of antioxidant 1010, 1 part of antioxidant 168, 5 parts of dimethyl tin, 10 parts of clay, and 1 part of light stabilizer 2020 were added to the high-speed kneader and kneaded, and the temperature in the kneader was controlled at 85°C, the kneading time is 5 minutes; 10 parts of nano-zinc oxide and 5 parts of silane coupling agent KH-550 are evenly added into the high-speed kneader, and the kneading temperature in the kneader is kept at 85°C, and kneading at constant temperature for 1 minute, the kneading process The internal pressure of the middle kneader is 0.4±0.1MPa;

[0052] (2) Extrusion cross-linking: After mixing evenly, ...

Embodiment 2

[0055] An environment-friendly cross-linked polyvinyl chloride waterproof membrane, the preparation process of which is as follows:

[0056] (1) Kneading: 20 parts of polyvinyl chloride powder (SG-2), 30 parts of ethylene-carbon monoxide copolymer (ECO), 5 parts of dipropylene glycol dibenzoate (DPGDB), 2 parts of vinyl triethoxysilane 10102 parts, 10102 parts of antioxidant, 1 part of antioxidant 168, 3 parts of dimethyl tin, 2 parts of Ca / Zn composite heat stabilizer, 20 parts of clay, 2.5 parts of light stabilizer 2020 were added to the high-speed kneader and kneaded, The temperature in the kneader is controlled at 85°C, and the kneading time is 5 minutes; 10 parts of nano zinc oxide and 1 part of titanate coupling agent NDZ-201 are evenly added to the high-speed kneader, and the kneading temperature in the kneader is kept at 85°C , kneading at constant temperature for 1 minute, and the pressure inside the kneader during the kneading process is 0.4±0.1MPa;

[0057] (2) Ext...

Embodiment 3

[0060] An environment-friendly cross-linked polyvinyl chloride waterproof membrane, the preparation process of which is as follows:

[0061] (1) Kneading: 35 parts of polyvinyl chloride powder (SG-3), 30 parts of ethylene-vinyl acetate (Va=60%), 10 parts of dipropylene glycol dibenzoate (DPGDB), 10 parts of vinyl triethoxy 1.5 parts of base silane, 10102 parts of antioxidant, 1 part of antioxidant 168, 5 parts of dioctyltin, 25 parts of clay, and 3 parts of light stabilizer 2020 were added to the high-speed kneader and kneaded. The temperature in the kneader was controlled at 85 ° C. The kneading time is 5 minutes; 10 parts of nano-zinc oxide and 3 parts of silane coupling agent KH-560 are evenly added to the high-speed kneader, and the kneading temperature in the kneader is kept at 85°C, and kneading at a constant temperature for 1 minute. During the kneading process, the kneader The internal pressure is 0.4±0.1MPa;

[0062] (2) Extrusion cross-linking: After mixing evenly, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com