Flexible metal oxide/N-doped graphene composite paper and preparation method and application thereof

A nitrogen-doped graphene and oxide technology, which is applied in the field of nanomaterial flexible devices, can solve the problems of easy falling off electrochemical performance and high resistance, and achieve the effects of reducing electron transfer resistance, low hydrothermal temperature and low pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Preparation

[0040] S1. Prepare 400ml of graphene oxide aqueous solution with a concentration of 0.5mg / ml. Under magnetic stirring conditions, add 16ml of 50wt% cyanamide aqueous solution dropwise. After the dispersion is uniform, put it in a water bath at 90°C for 24h. After the reaction is completed, filter and freeze-dry , grinding to obtain nitrogen-doped graphene;

[0041] S2. Measure 180ml of absolute ethanol, weigh 30mg of nitrogen-doped graphene, and after ultrasonic dispersion is uniform, add 2.25ml of TiCl with a concentration of 0.8mol / l dropwise under stirring conditions 4 / absolute ethanol solution, then dropwise add 4ml deionized water, stir for 90min, obtain uniformly dispersed nitrogen-doped graphene and TiCl 4 the dispersion liquid;

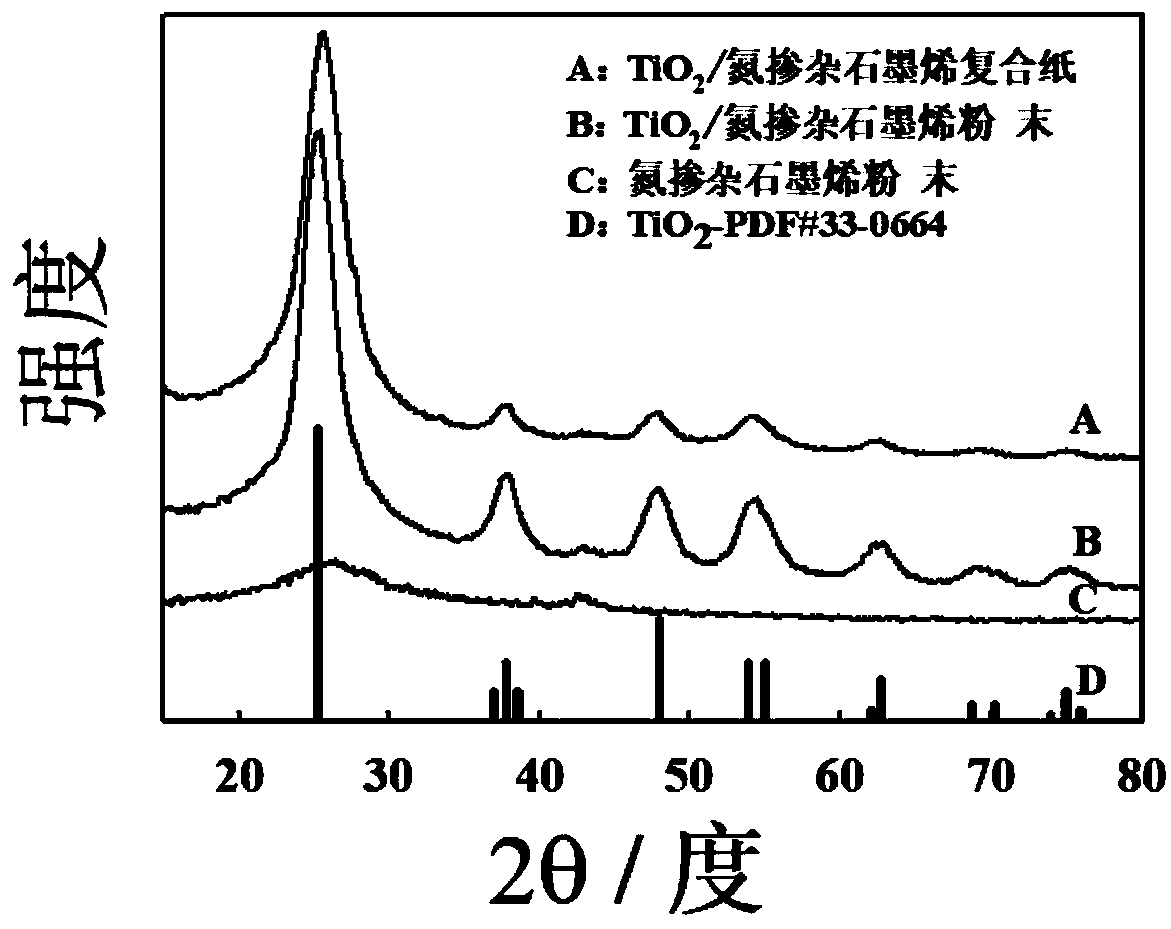

[0042] S3. Transfer the dispersion to a 200ml hydrothermal kettle, react at 120°C for 2 hours, cool to room temperature after the reaction, and then filter, dry, and grind to obtain powdered TiO 2 / Nitrogen-doped g...

Embodiment 2

[0048] 1. Preparation

[0049] S1. Prepare 200 mg of graphene oxide aqueous solution, add 5 g of urea aqueous solution dropwise under the condition of magnetic stirring, and after the dispersion is uniform, bathe in 80°C water bath for 30 hours. After the reaction is completed, filter, freeze-dry, and grind to obtain nitrogen-doped graphene;

[0050] S2. Measure 180ml of absolute ethanol, weigh 30mg of nitrogen-doped graphene, and after ultrasonic dispersion is uniform, add 6ml of FeCl with a concentration of 0.5mol / l dropwise under stirring conditions 3 / methanol solution, then dropwise add 8ml deionized water, stir for 100min, obtain uniformly dispersed nitrogen-doped graphene and FeCl 3 the dispersion liquid;

[0051] S3. Transfer the dispersion to a 200ml hydrothermal kettle, react at 130°C for 1.5h, cool to room temperature after the reaction, and then filter, dry, and grind to obtain powdered Fe 2 o 3 / Nitrogen-doped graphene composite materials;

[0052] S4. Measure...

Embodiment 3

[0057] 1. Preparation

[0058] S1. Prepare 200mg of graphene oxide aqueous solution, add 16ml of melamine aqueous solution dropwise under the condition of magnetic stirring, after the dispersion is uniform, put it in a water bath at 140°C for 1 hour, after the reaction is completed, filter, freeze-dry, and grind to obtain nitrogen-doped graphene;

[0059] S2. Measure 180ml of absolute ethanol, weigh 30mg of nitrogen-doped graphene, and ultrasonically disperse evenly. Under stirring conditions, add 1ml of Sn(NO 3 ) 4 / dehydrated ethanol solution, then drop 2ml deionized water, stir for 120min, obtain uniformly dispersed nitrogen-doped graphene and Sn(NO 3 ) 4 the dispersion liquid;

[0060] S3. Transfer the dispersion to a 200ml hydrothermal kettle, react at 110°C for 12h, cool to room temperature after the reaction, and then filter, dry, and grind to obtain powdered SnO 2 / Nitrogen-doped graphene composite materials;

[0061] S4. Measure 1.5ml of graphene oxide with a con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com