Halogen-free low-smoke flame-retardant cable material and preparation method thereof

A low-smoke flame-retardant and cable material technology, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve problems such as hazards, a large amount of toxic smoke, and the reduction of mechanical properties of cable materials, so as to block conduction and inhibit Open flame generation, avoiding the effects of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

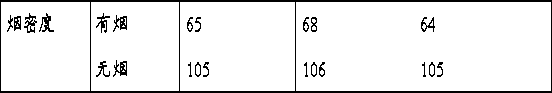

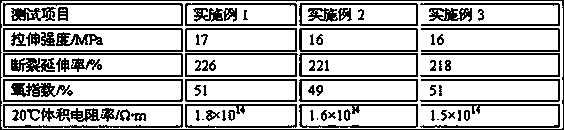

Embodiment 1

[0039] A halogen-free low-smoke flame-retardant cable material, comprising the following raw materials by weight: 82 parts of polyvinyl chloride, 2 parts of a mixture of molybdenum oxide and copper oxide, 8 parts of expandable graphite, lemon modified by polyvinyl butyral 6 parts of triethyl acid, 18 parts of a mixture of perlite and talc, 2 parts of a mixture of hindered phenol antioxidants: thioester antioxidants=1:2.

[0040] Weigh the raw materials according to the number of parts of the composition ratio; put the accurately weighed polyvinyl chloride, plasticizer, and filler into the mixer and mix for 8 minutes, and then add the weighed smoke suppressant and the Expanded graphite and antioxidant, continue to add to the mixer and stir until the mixing is complete; mix the above-mentioned homogeneously mixed raw materials in a kneader at 100°C for 8 minutes to obtain a homogeneous mixture; add the obtained homogeneous mixture to the twin screw The extruder is plasticized, extr...

Embodiment 2

[0043] A halogen-free low-smoke flame-retardant cable material, comprising the following raw materials: 75 parts by weight of polyvinyl chloride, 4 parts of a mixture of ammonium molybdate and chromium oxide, 10 parts of expandable graphite, modified by polyvinyl butyral 8 parts of triethyl citrate, 20 parts of a mixture of perlite, light calcium carbonate and talc, 3 parts of a mixture of hindered phenol antioxidants: thioester antioxidants=1:3.

[0044] Weigh the raw materials according to the number of parts of the composition ratio; put the accurately weighed polyvinyl chloride, plasticizer and filler into the mixer and mix for 10 minutes, and then add the weighed smoke suppressant and the Expanded graphite and antioxidant, continue to add to the mixer and stir until the mixing is complete; mix the above-mentioned homogeneously mixed raw materials in a kneader at 110°C for 8 minutes to obtain a homogeneous mixture; add the obtained homogeneous mixture to the twin screw The ex...

Embodiment 3

[0047] A halogen-free low-smoke flame-retardant cable material, comprising the following raw materials by weight: 90 parts of polyvinyl chloride, 0.5 parts of a mixture of molybdenum oxide, iron oxide, and zinc oxide, 5 parts of expandable graphite, modified by polyvinyl butyral 3 parts of epoxy octyl stearate, 16 parts of a mixture of kaolin, talc and light calcium carbonate, 1 part of a mixture of hindered phenol antioxidants: thioester antioxidants=1:2.

[0048] Weigh each raw material according to the composition ratio; put the accurately weighed polyvinyl chloride, plasticizer, and filler into the mixer and mix for 5 minutes, and then add the weighed smoke suppressant, Expanded graphite and antioxidant, continue to add to the mixer and stir until the mixing is complete; mix the above-mentioned homogeneously mixed raw materials in a kneader at 90°C for 6 minutes to obtain a homogeneous mixture; add the obtained homogeneous mixture to the twin screw The extruder is plasticized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com