Water-based, flame-retardant, thermal-insulation and self-cleaning coating for steel structures and preparation method of coating

A thermal insulation and self-cleaning technology, applied in the direction of anti-fouling/underwater coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of high cost, environmental pollution, difficult anti-corrosion performance, etc., achieve low cost, convenient construction, The effect of easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

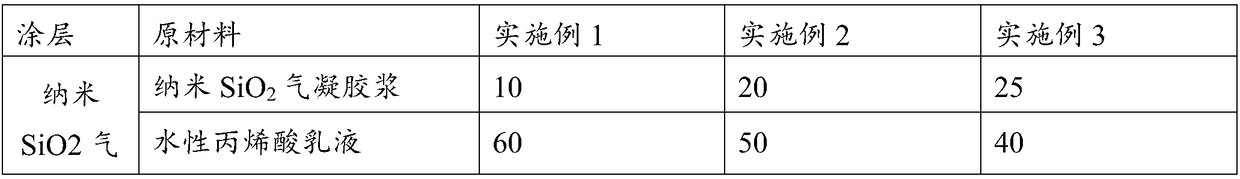

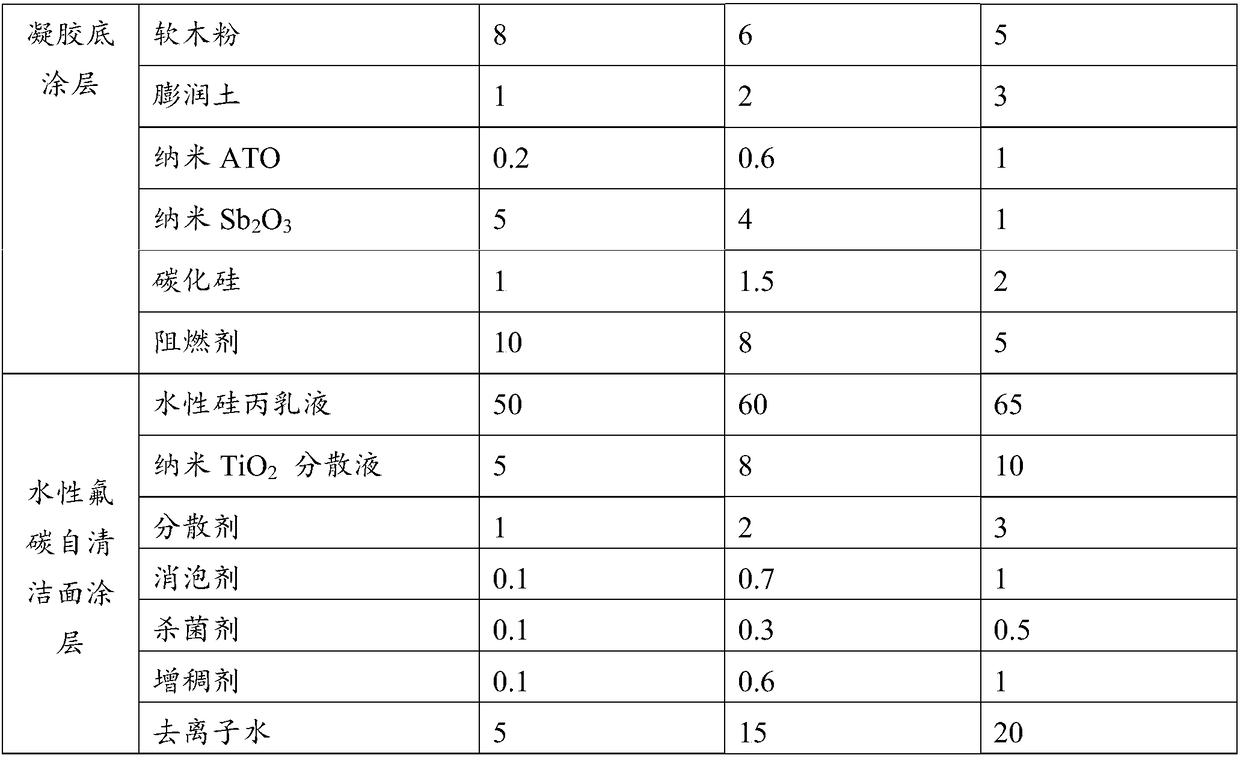

Examples

preparation example Construction

[0051] The present invention also provides a method for preparing a water-based steel structure with flame-retardant heat-insulating self-cleaning coating, comprising the following steps:

[0052] Step S110: preparing an aqueous acrylic emulsion.

[0053] In some preferred embodiments, the preparation of aqueous acrylic emulsion comprises the following steps:

[0054] Step S111: After mixing deionized water, emulsifier, initiator and pH buffering agent, the temperature is raised to 65-75° C. to form a first mixed solution;

[0055] Step S112: Mix the acrylate monomer, the organosilicon monomer, the hydrolysis inhibitor and the first mixed solution evenly, then raise the temperature to 70-85° C., and keep it warm for 2-3 hours to form a second mixed solution;

[0056] Step S113: cooling the second mixed solution to below 45°C, adjusting the pH to 7-8 with triethylamine, and obtaining the aqueous silicon-acrylic emulsion after discharging;

[0057] The water-based silicone acr...

Embodiment 1

[0068] According to the mass parts of Example 1 in Table 1, the water-based exterior wall thermal insulation self-cleaning coating is prepared, and its preparation method is as follows:

[0069] The first step: prepare water-based acrylic emulsion, comprising the following steps:

[0070] 1) In a four-necked round-bottom flask equipped with a stirring rod, a thermometer, a condenser tube, and a constant pressure funnel, add 41 g of deionized water, 4 g of sodium dodecylbenzenesulfonate, 0.2 g of ammonium persulfate and 0.2 g of sodium bicarbonate g, warming up to 65°C, stirring at 200 rpm;

[0071] 2) Mix 35g of butyl acrylate monomer, 4g of hydroxyethyl methacrylate, 10g of vinyltrimethoxysilane, and 2g of propylene glycol, put them in a constant pressure funnel, drop them into the above-mentioned four-necked flask at a constant speed, and add dropwise After completion, the temperature was raised to 70° C., and the reaction was kept for 3 hours;

[0072] 3) After the reacti...

Embodiment 2

[0076] According to the mass parts of embodiment 2 in table 1, prepare water-based external wall thermal insulation self-cleaning coating, its preparation method is as follows:

[0077] The first step: prepare water-based acrylic emulsion, comprising the following steps:

[0078] 1) In a four-necked round-bottomed flask equipped with a stirring rod, a thermometer, a condenser, and a constant pressure funnel, add 50 g of deionized water, 6 g of octylphenol polyoxyethyl ether, 0.4 g of sodium bisulfite and 0.3 g of sodium bicarbonate g, heat up to 75°C, and stir at 200 rpm.

[0079] 2) Mix 30g of butyl propacrylate monomer, 20g of methyl methacrylate, 5g of hydroxyethyl methacrylate, 2g of vinyltriethoxysilane, and 5g of propylene glycol, place in a constant pressure funnel, and drop at a constant speed Add it into the above-mentioned four-neck flask. After the dropwise addition is completed, the temperature is raised to 85° C., and the reaction is kept for 2 hours.

[0080] 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com