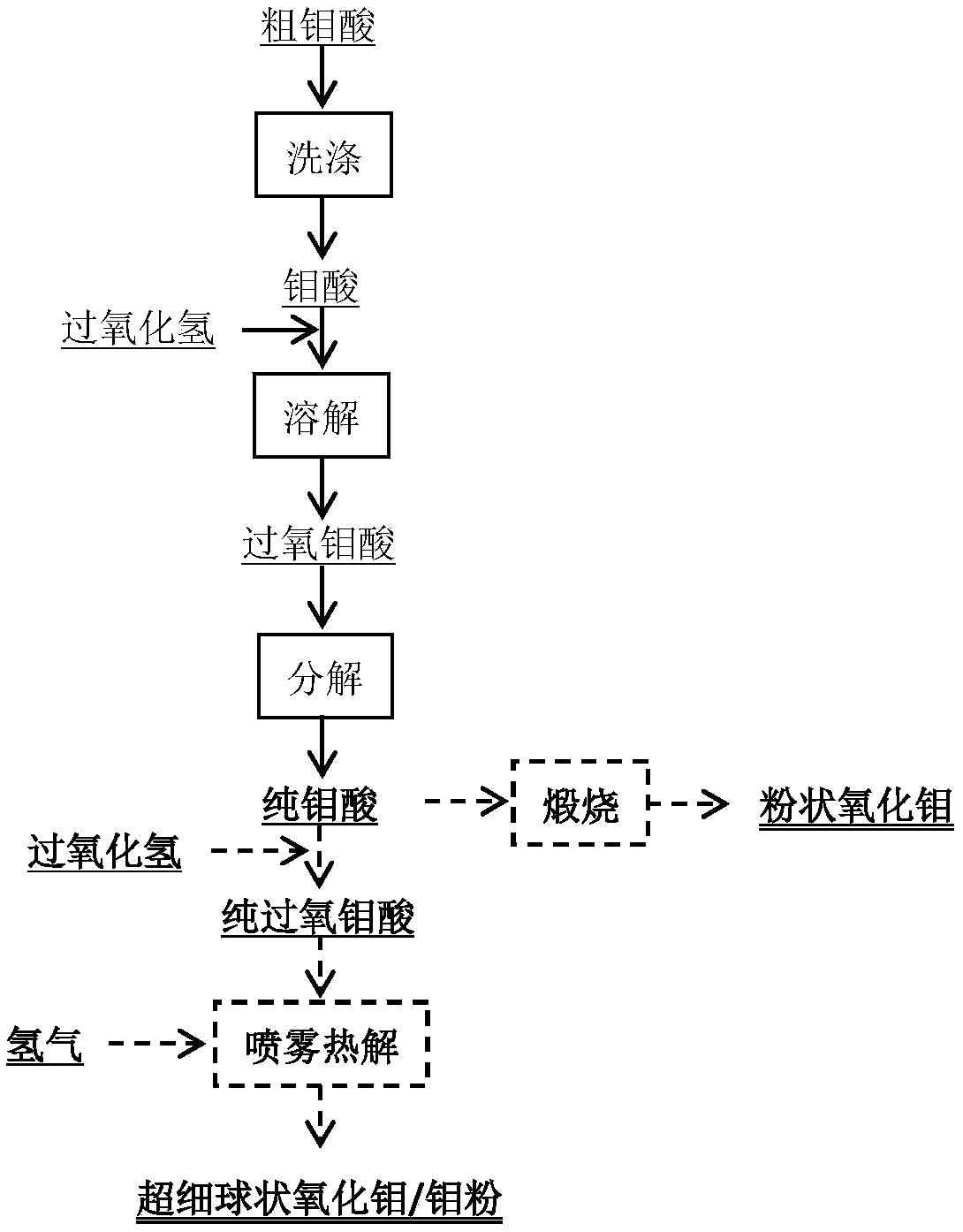

Method for extracting molybdenum from crude molybdic acid and preparing molybdenum product

A technology of molybdenum acid and products, which is applied in the field of extracting molybdenum and preparing molybdenum products, can solve the problems of high cost, many procedures, and long molybdenum product process, and achieve the effects of increasing product added value, shortening the process flow, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] First, the sodium molybdate solution was acid-precipitated to obtain crude molybdic acid with a Mo content of 48%.

[0034] A method for extracting molybdenum from crude molybdic acid and preparing a molybdenum product, comprising the steps of:

[0035] (1) The crude molybdic acid with the Mo content of 48% is added to the hydrogen peroxide solution of 30% for dissolving, the controlled reaction temperature is 35° C., and the reaction time is 0.5 hour. After the reaction is completed, it is filtered to obtain Insoluble slag and peroxymolybdic acid solution;

[0036] (2) directly heating the peroxomolybdic acid that step (1) obtains to 90 DEG C, until peroxomolybdic acid is completely decomposed and desorbed molybdic acid;

[0037] (3) after step (2) gained molybdic acid is washed, again molybdic acid is joined in concentration and is dissolved in the hydrogen peroxide solution of 30%, and control reaction temperature is 35 ℃, and the reaction times is 0.5 hour; Obtaine...

Embodiment 2

[0041] First, molybdenite is decomposed under oxygen pressure to obtain crude molybdic acid with a Mo content of 46.5%.

[0042] A method for extracting molybdenum from crude molybdic acid and preparing a molybdenum product, comprising the steps of:

[0043] (1) adding the crude molybdic acid with a Mo content of 46.5% to a hydrogen peroxide solution with a concentration of 28% for dissolving, controlling the reaction temperature to be 15° C., and the reaction time to be 2.0 hours, after the reaction is completed, obtain an insoluble slag by filtering and peroxomolybdic acid solution;

[0044] (2) pass into SO in the peroxymolybdic acid solution that step (1) obtains 2 And control the pH value of the solution to be 1.5, until the complete decomposition of molybdic acid peroxymolybdic acid;

[0045] (3) after step (2) gained molybdic acid is washed, again molybdic acid is joined in concentration and is dissolved in the hydrogen peroxide solution of 28%, and control reaction tem...

Embodiment 3

[0048] First, the sodium molybdate solution is acid-decomposed to obtain crude molybdic acid with a Mo content of 50%.

[0049] A method for extracting molybdenum from crude molybdic acid and preparing a molybdenum product, comprising the steps of:

[0050] (1) adding the above-mentioned thick molybdic acid with a Mo content of 50% into a hydrogen peroxide solution of 30% for dissolving, controlling the reaction temperature to be 25° C., and the reaction time to be 1.0 hour, after the reaction is completed, the insoluble slag is obtained by filtration and peroxomolybdic acid solution;

[0051] (2) directly heating to 90 ℃ to the peroxomolybdic acid solution that step (1) obtains, until peroxomolybdic acid is completely decomposed and desorbed molybdic acid;

[0052] (3) After the molybdic acid obtained in step (2) is washed, it is mixed with a mass concentration of 30% hydrogen peroxide solution for 1 h at a temperature of 40° C. to obtain a pure peroxomolybdic acid solution;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com