ZnO/Ag2O photocatalysis composite material, as well as preparation method and application thereof

A composite material and photocatalytic technology, which is applied in the field of preparation of metal oxide semiconductor photocatalytic composite materials, can solve the problems of difficult recovery of by-products, long reaction time, high-temperature calcination, etc., and achieve excellent photocatalytic activity, catalytic performance improvement, Reduce the effect of compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: ZnO / Ag with a mass ratio of 10% silver oxide 2 Preparation of O composites

[0023] (1) 20g of sodium nitrate, 7.5g of zinc nitrate hexahydrate, and 0.29g of silver nitrate are mixed in an agate mortar, ground for 15 minutes until evenly mixed, and spread on the bottom of the agate mortar to obtain a premix;

[0024] (2) Add 2.069g of sodium hydroxide to the pre-mixture, grind for 25 minutes to mix evenly, and obtain the crude product;

[0025] (3) The crude product is washed with deionized water, then filtered and dried to obtain ZnO / Ag with 10% silver oxide mass proportion 2 O composite materials.

Embodiment 2

[0026] Example 2: ZnO / Ag with a mass ratio of 30% silver oxide 2 Preparation of O composites

[0027] (1) 20g of sodium nitrate, 7.5g of zinc nitrate hexahydrate, and 0.88g of silver nitrate are mixed in an agate mortar, ground for 25 minutes until evenly mixed, and spread on the bottom of the agate mortar to obtain a premix;

[0028] (2) Add 2.21g of sodium hydroxide to the premixture, grind for 25 minutes to mix evenly, and obtain the crude product;

[0029] (3) The crude product is washed with deionized water, then filtered and dried to obtain ZnO / Ag with a mass ratio of 30% silver oxide 2 O composite materials.

Embodiment 3

[0030] Example 3: ZnO / Ag with a mass ratio of 50% silver oxide 2 Preparation of O composites

[0031] (1) 20g of sodium nitrate, 7.5g of zinc nitrate hexahydrate, and 1.47g of silver nitrate are mixed in an agate mortar, ground for 15 minutes until evenly mixed, and spread on the bottom of the agate mortar to obtain a premix;

[0032] (2) Add 2.35g of sodium hydroxide to the premixture, grind for 25 minutes to mix evenly, and obtain the crude product;

[0033] (3) The crude product is washed with deionized water, then filtered and dried to obtain ZnO / Ag with 50% silver oxide mass proportion 2 O composite materials.

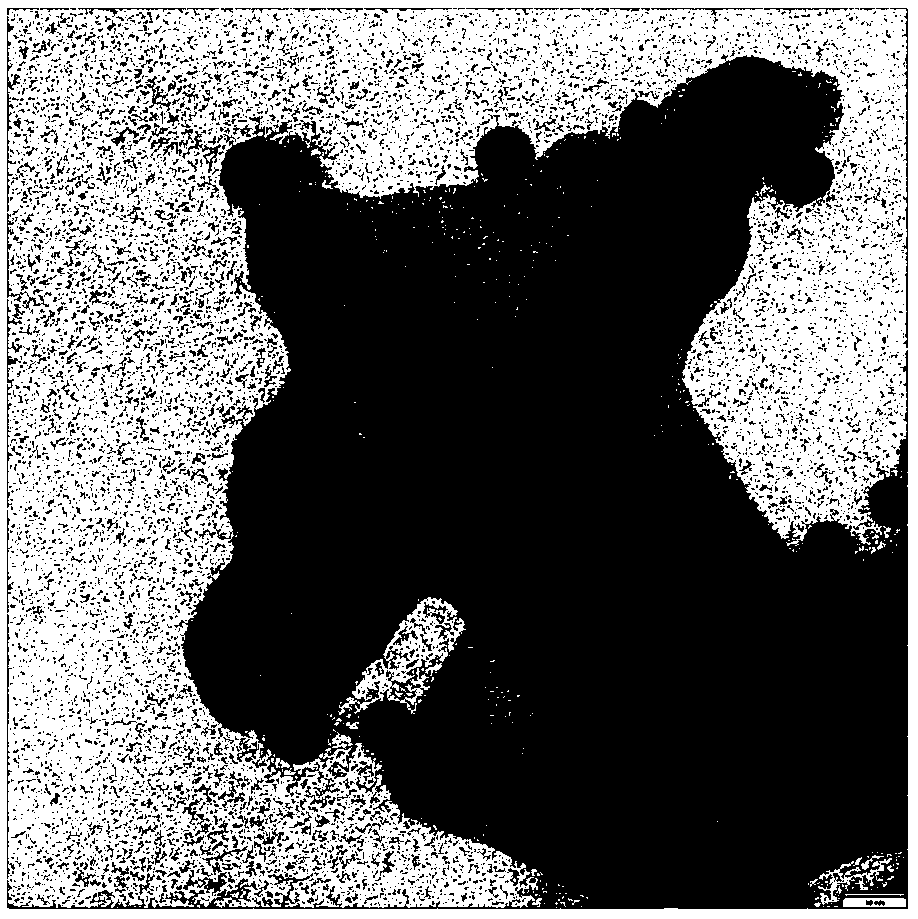

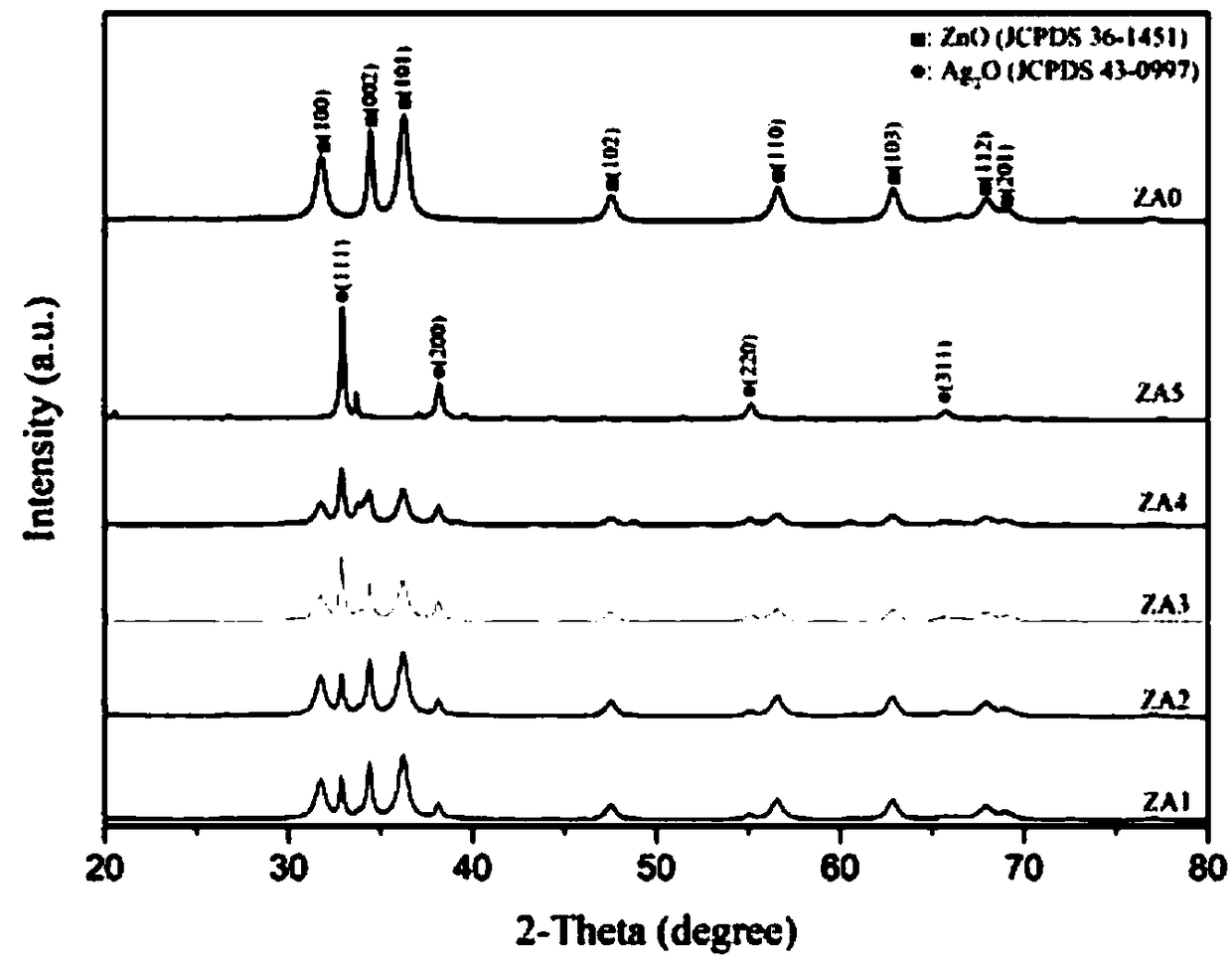

[0034] Its TEM picture is as follows figure 1 As shown, we can see from the figure that the black Ag with a diameter of about 10nm 2 O particles are attached to the ZnO flakes.

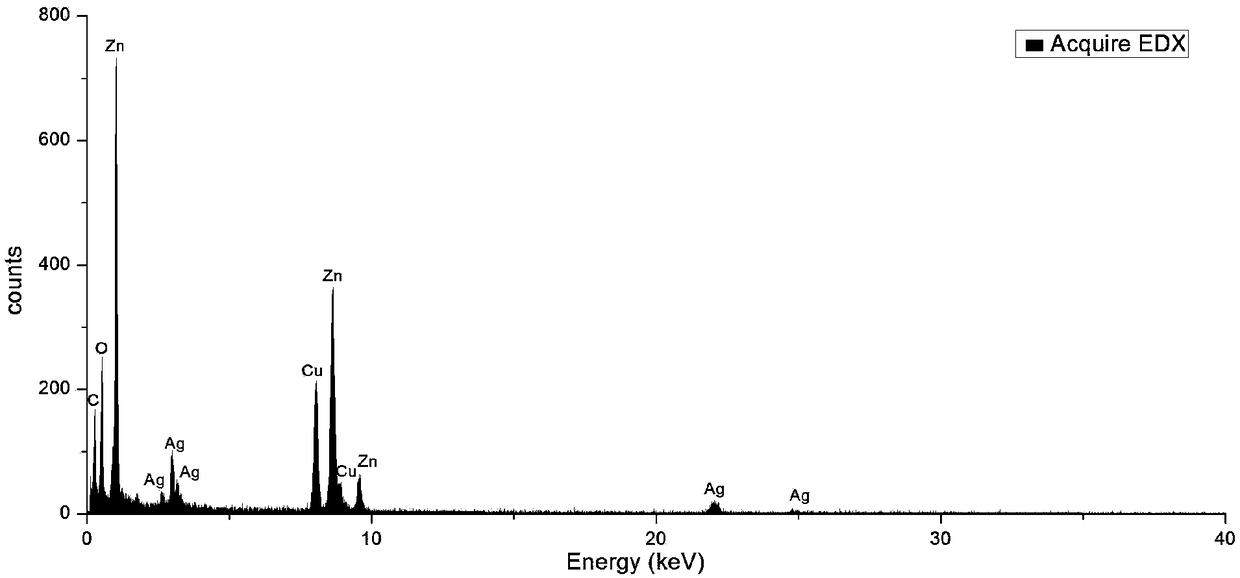

[0035] Its EDX diagram is as follows figure 2 Shown, from the figure we can see that the final product ZnO / Ag that embodiment 3 obtains 2 The O composite material is composed of Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice parameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com