Cathode material for graphene battery and preparation method thereof

A cathode material, graphene technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low specific capacity and poor cycle life, and achieve the effect of high specific capacity, improved cycle life, and large specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides above-mentioned a kind of preparation method for the cathode material of graphene battery, comprises the following steps:

[0034] a) In a vacuum environment in a vacuum glove box, add carbon black, titanium, platinum, tungsten, molybdenum, and lithium to the polyimide conductive adhesive and stir evenly, then smear it on the surface of the substrate, and dry it to obtain the primary cathode substrate material;

[0035] b) oxidizing the graphite into graphite oxide, and dispersing the graphite oxide in deionized medium, adding a reducing agent to obtain a pre-reduced graphene solution;

[0036] c) coating the pre-reduced graphene solution obtained in step b) on the surface of the primary cathode substrate, and performing laser irradiation and drying to obtain the cathode material for the graphene battery.

[0037] In the above technical scheme, by first coating the mixture of carbon black, titanium, platinum, tungsten, molybdenum, li...

Embodiment 1

[0044] Weigh 5g of particle size as 300 mesh flake graphite and 2gNaNO 3 For relaxation, add 120mL of concentrated sulfuric acid and place in an ice-water bath for stirring. After 30min, add 20g of KMnO 4 , after reacting for 60 minutes, move it into a warm water bath at 40°C and continue to react for 30 minutes, then slowly add 230mL deionized water, and keep the reaction temperature at 98°C, stir for 5 minutes, add an appropriate amount of hydrogen peroxide until no bubbles are generated, filter while hot, and use deionized Wash with water and 5% hydrochloric acid several times until neutral, and after centrifugation, fully dry in a vacuum oven at 60°C to obtain graphite oxide.

Embodiment 2

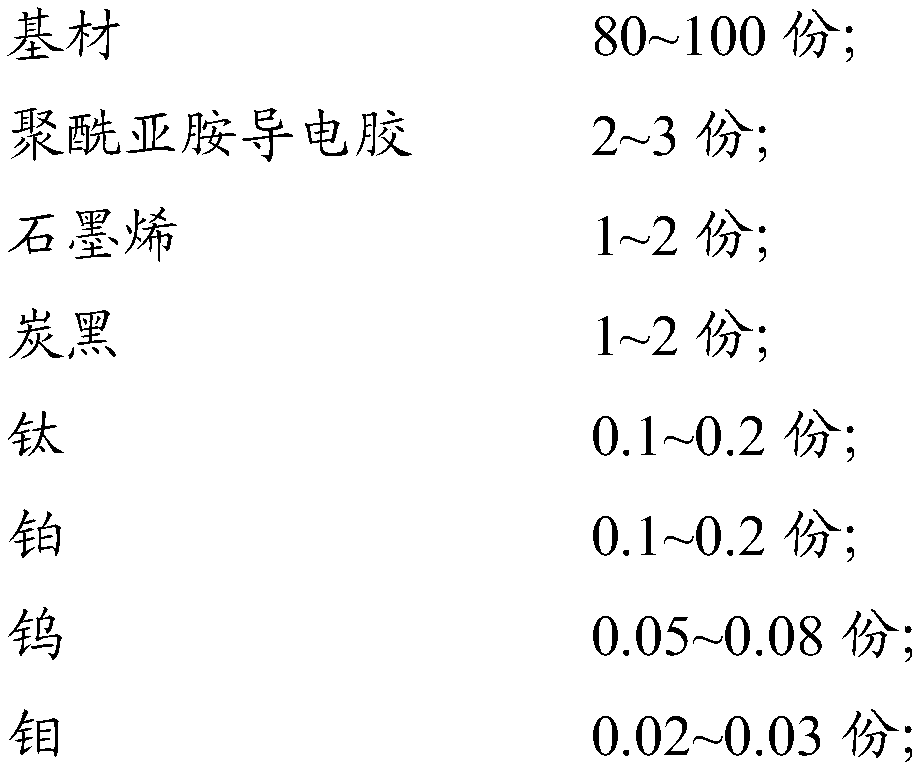

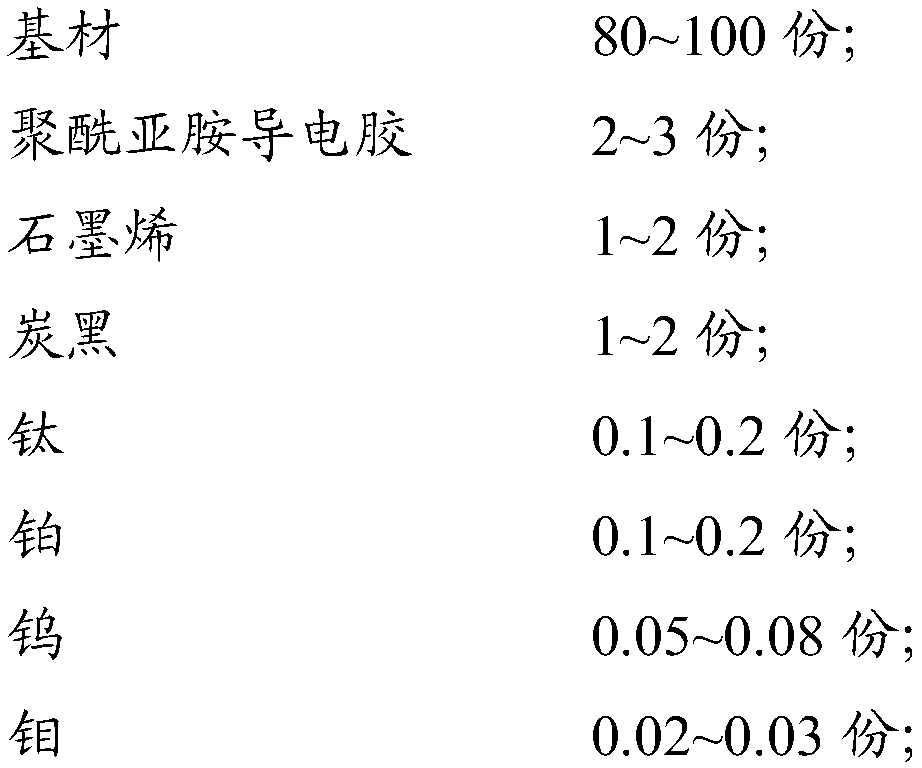

[0046] For the cathode material of graphene battery, comprise the raw material of following parts by weight:

[0047]85g carbon rod, 2.2g polyimide conductive glue, 1g carbon black, 0.12g titanium, 0.11g platinum, 0.07g tungsten, 0.026g molybdenum, 0.13g lithium;

[0048] A preparation method for a cathode material of a graphene battery, comprising the following steps:

[0049] a) In a vacuum environment in a vacuum glove box, add carbon black, titanium, platinum, tungsten, molybdenum, and lithium to the polyimide conductive adhesive and stir evenly, then smear it on the surface of the carbon rod, and obtain the primary cathode base after drying. material;

[0050] B) disperse in the graphite oxide that 1.5g embodiment 1 makes in deionization, add reducing agent, obtain pre-reduced graphene solution;

[0051] c) coating the pre-reduced graphene solution obtained in step b) on the surface of the primary cathode substrate, and performing laser irradiation and drying to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com